Detecting soot during real time operation in diesel engine lubricant

a technology of real-time operation and diesel engine, which is applied in the direction of vehicle position/course/altitude control, process and machine control, instruments, etc., can solve the problems of engine lubricant oil contamination, increase in the rate of soot blowing past the engine piston rings, and inability to effectively perform the function of engine lubrican

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

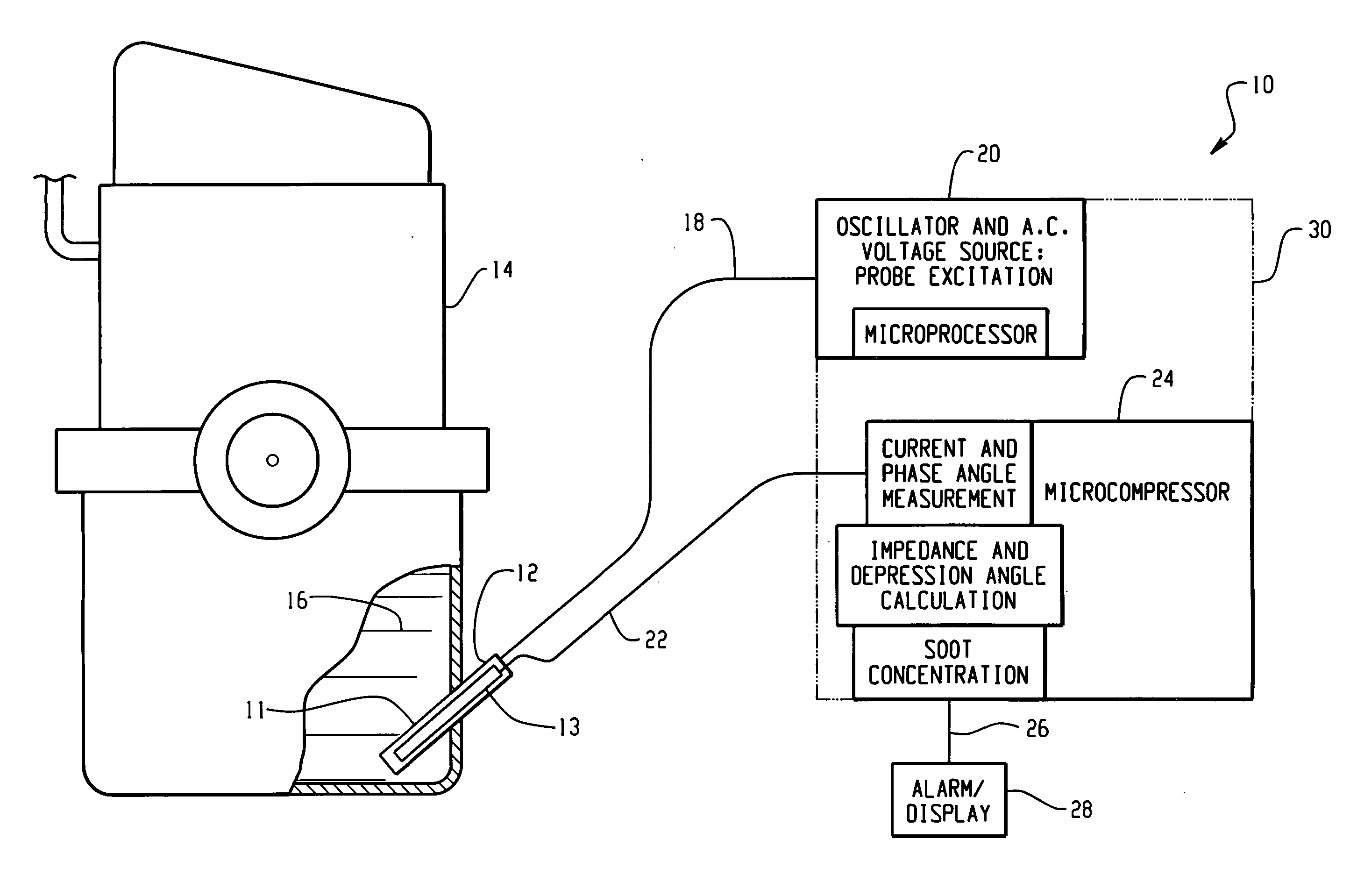

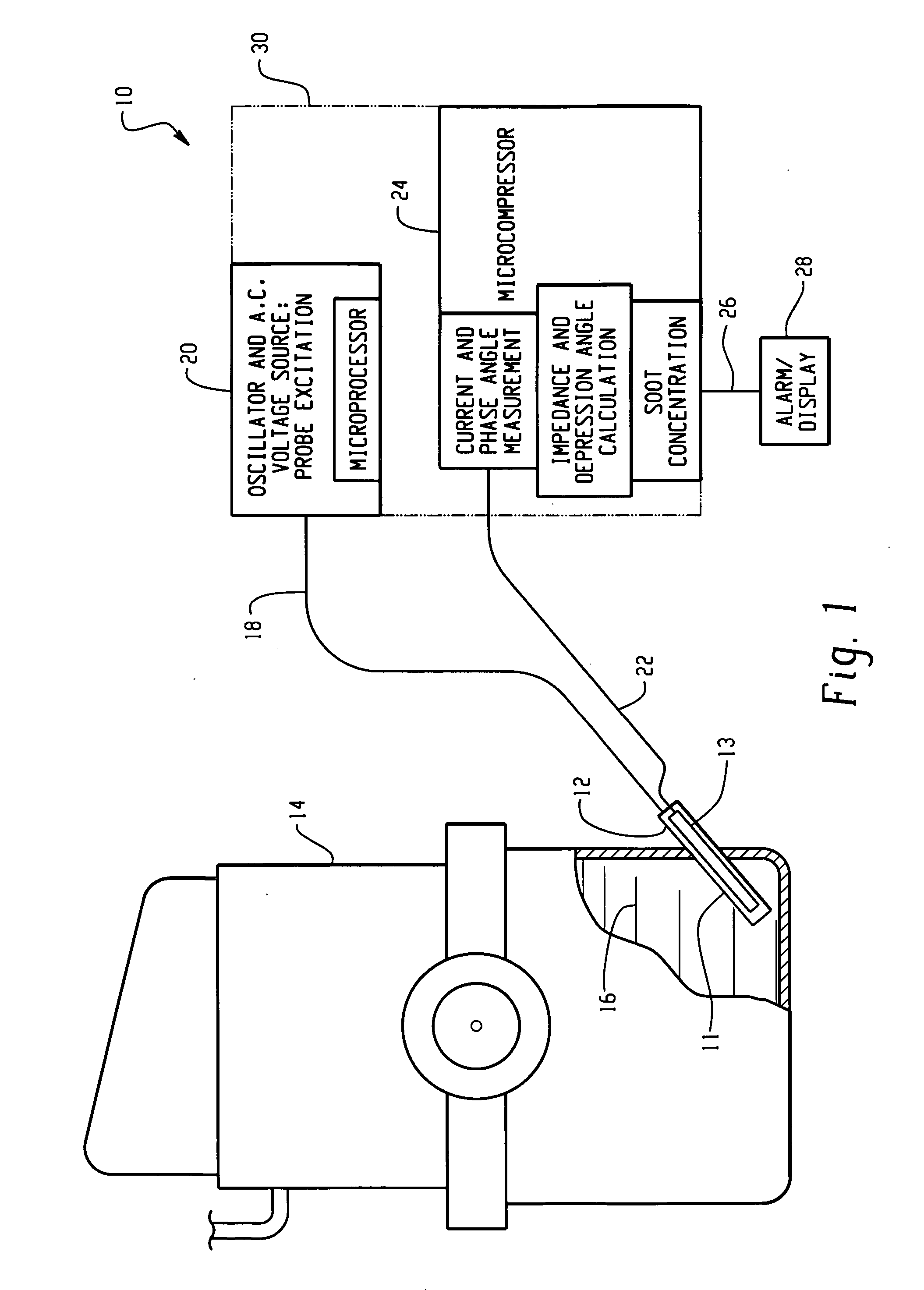

[0010] The system of the present invention is indicated generally at 10 and includes a probe 12 inserted into the crankcase or sump of a diesel engine 14 filled with lubricant to a level indicated at 16. The probe may have any suitable electrode configuration; however, in the present practice of the invention it has been found satisfactory to use a pair of concentric tubularly configured concentric electrodes denoted by reference numerals 11, 13 in FIG. 1. This probe may be configured as set forth in co-pending application Ser. No. 10 / 060,107 filed Jan. 31, 2002, entitled “Probe Assembly For Fluid Condition Monitor And Method Of Making Same” and assigned to the assignee of the present application.

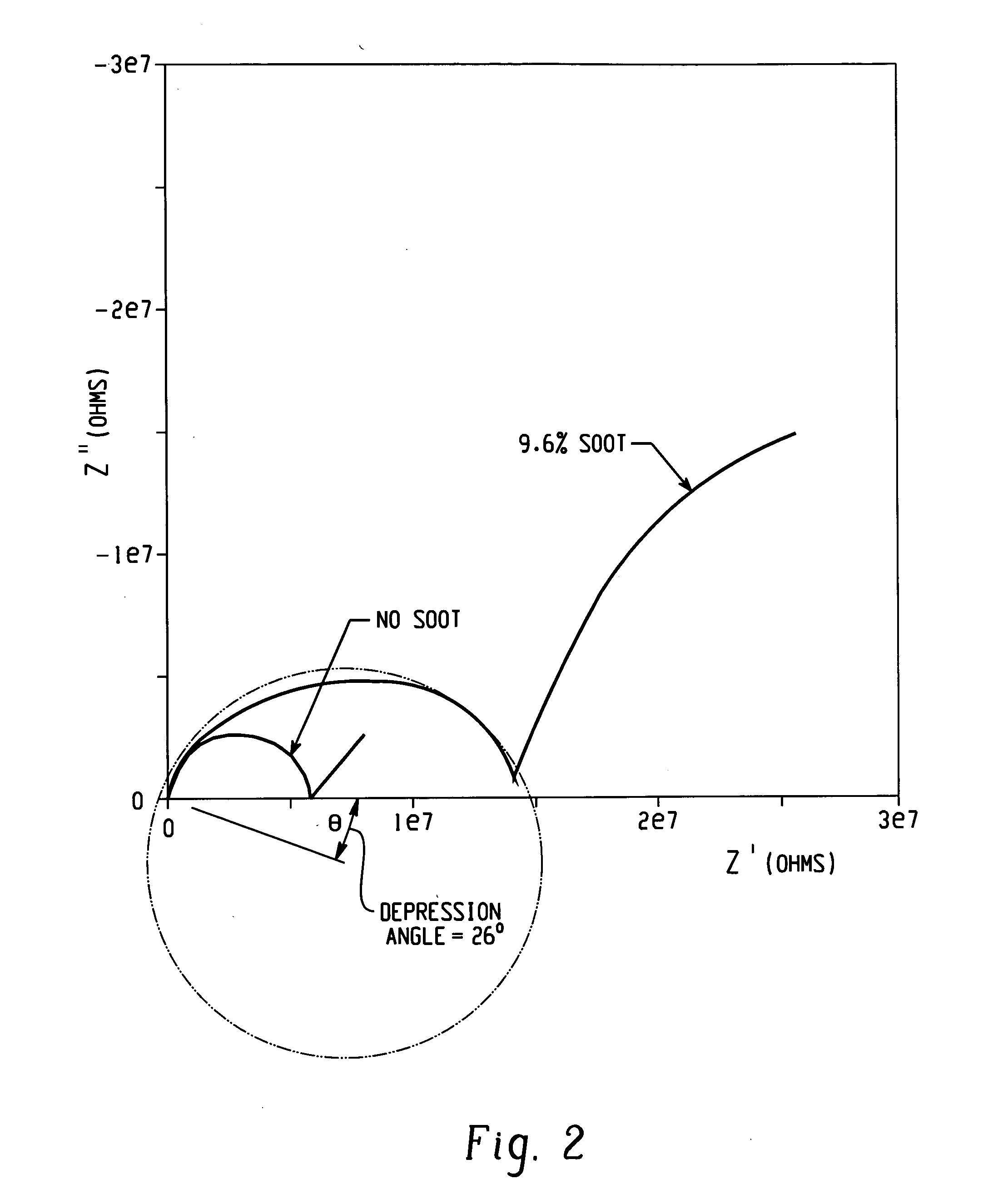

[0011] The probe 12 has one electrode excited along line 18 with a relatively low voltage AC current from a controller 20 which may include an oscillator and microprocessor for providing a relatively low voltage source of AC current to the probe. The probe current measured by connection th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequencies | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com