Cordless chop saw

a cordless, chop saw technology, applied in the field of chop saws, can solve the problems of increasing labor and building costs, users not being able to use chop saws, and none of these options are availabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

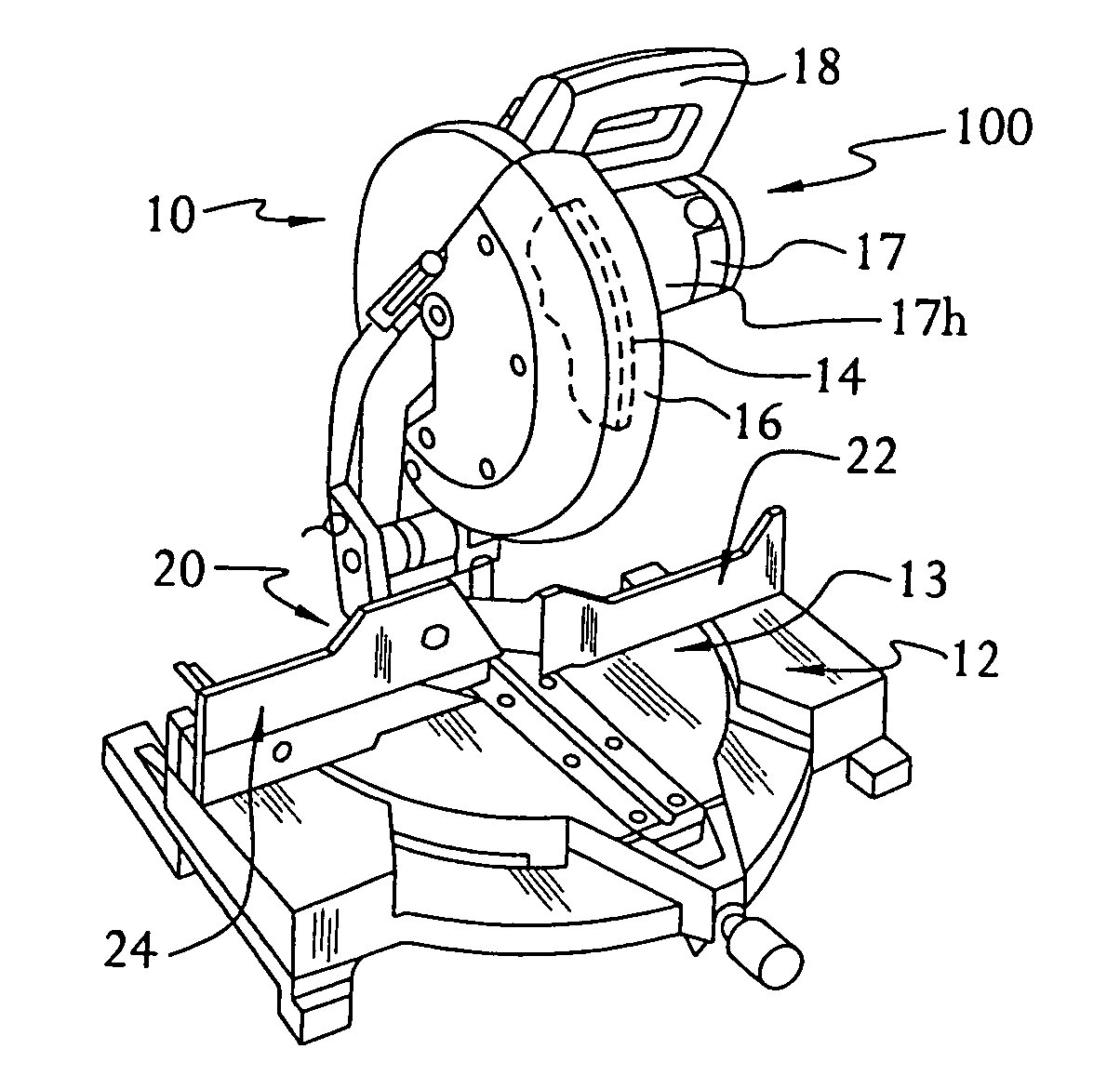

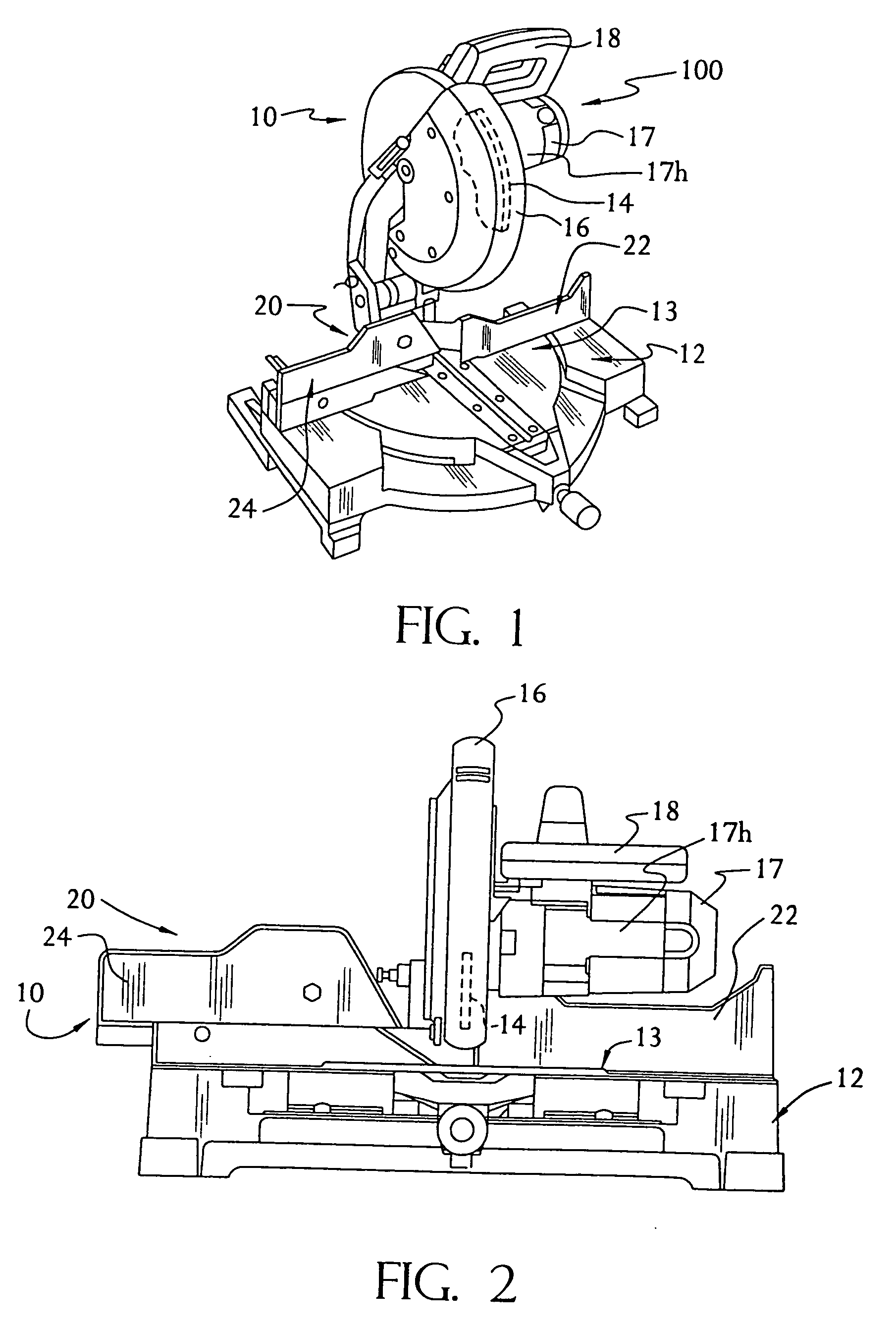

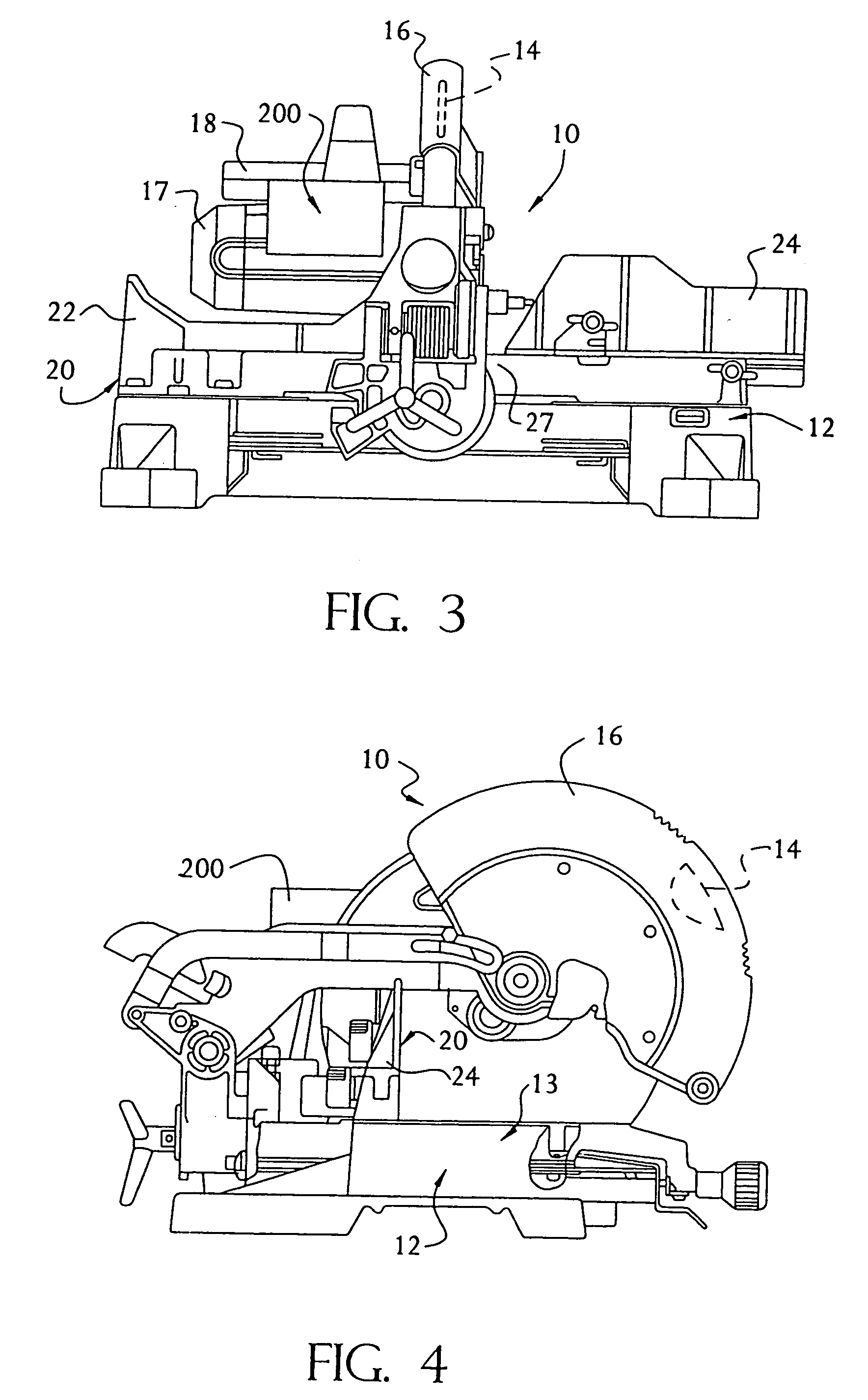

[0016] The invention is now described with reference to the accompanying figures, wherein like numerals designate like parts. FIGS. 1 through 4 illustrate an exemplary chop saw, which can be mitered. One skilled in the art will readily recognize from the following description that the principles of the invention are equally applicable to compound miter saws, sliding miter saws, non-mitering chop saws, etc.

[0017] The exemplary chop saw 10 according to the present invention typically includes a base 12, including a table 13, which is preferably rotatable about an axis perpendicular to the top surface plane of table 13. The saw 10 also includes a saw unit 100 pivotably attached to the table 13. The saw unit comprises a saw blade 14, at least partially enclosed by a blade guard 16 and driven by a motor 17, and a handle 18, which allows the operator to move the saw blade 14 and the blade guard 16 from a clear position free of a workpiece (not shown) to a downward cutting position with t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voltage | aaaaa | aaaaa |

| voltage rating | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com