Tool case

a tool and case technology, applied in the field of tool cases, can solve the problems that the socket of a ratchet wrench is especially difficult to remove from the cavity of a tool with a smooth outer surface, and achieve the effect of convenient and convenient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

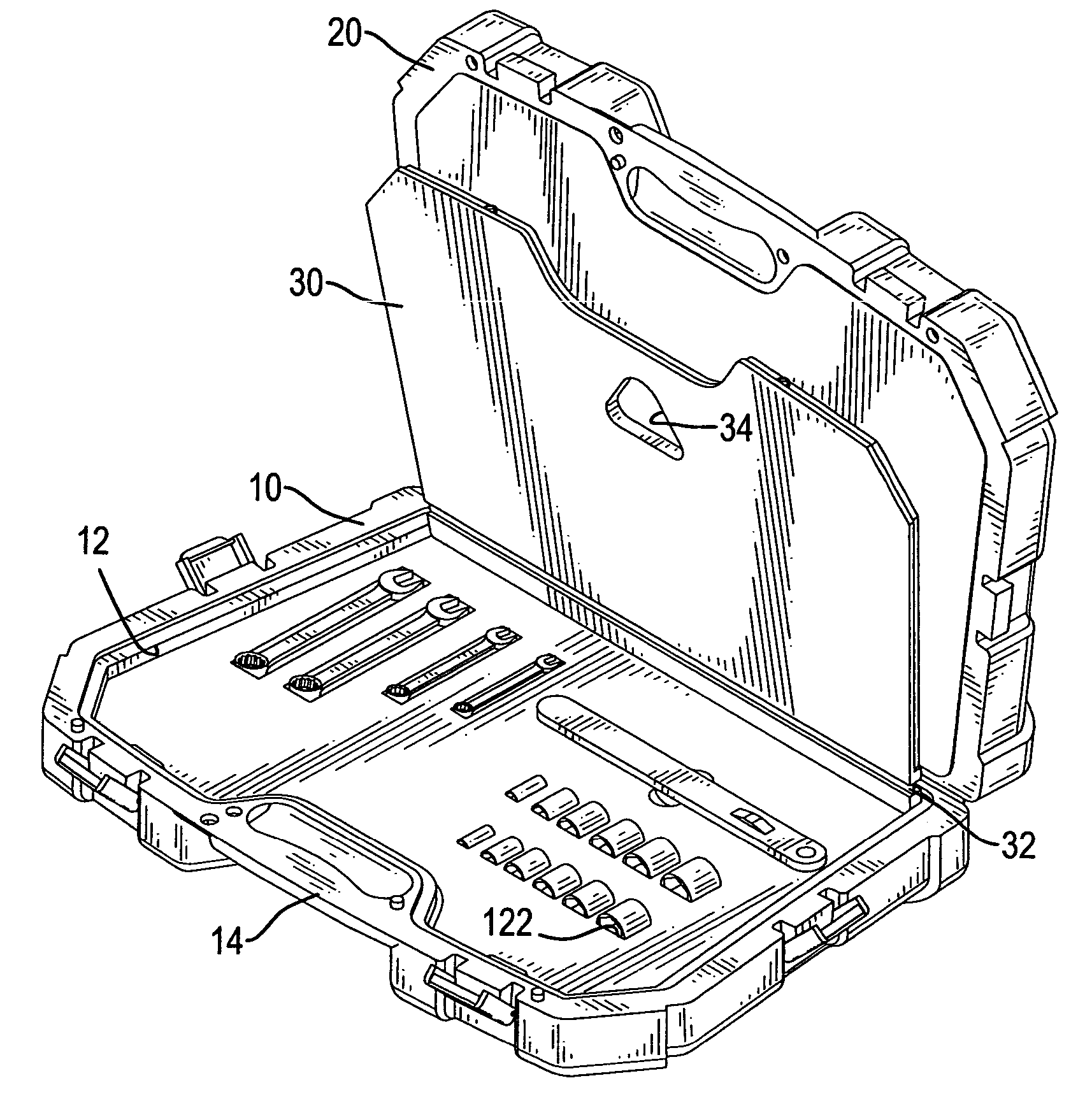

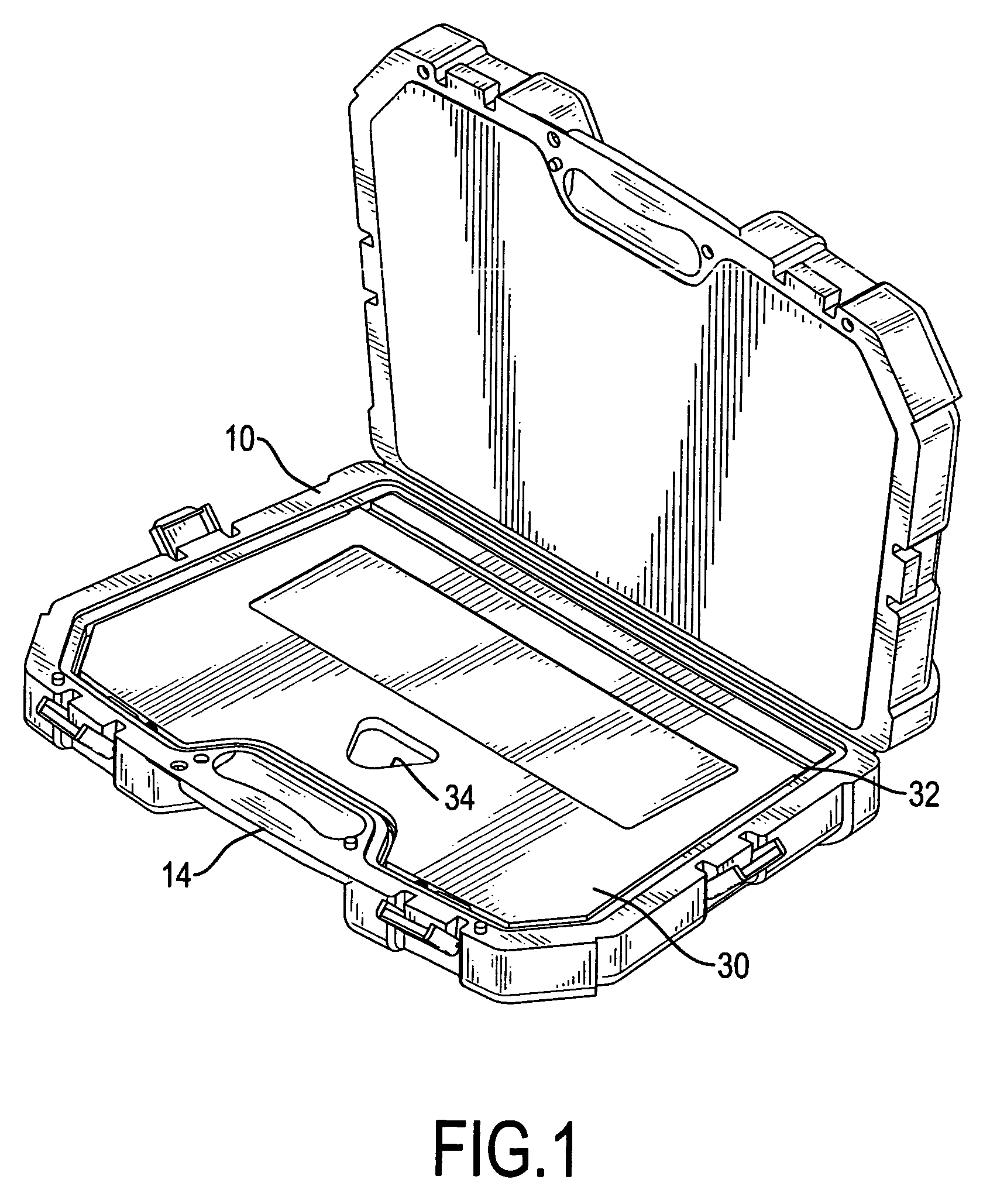

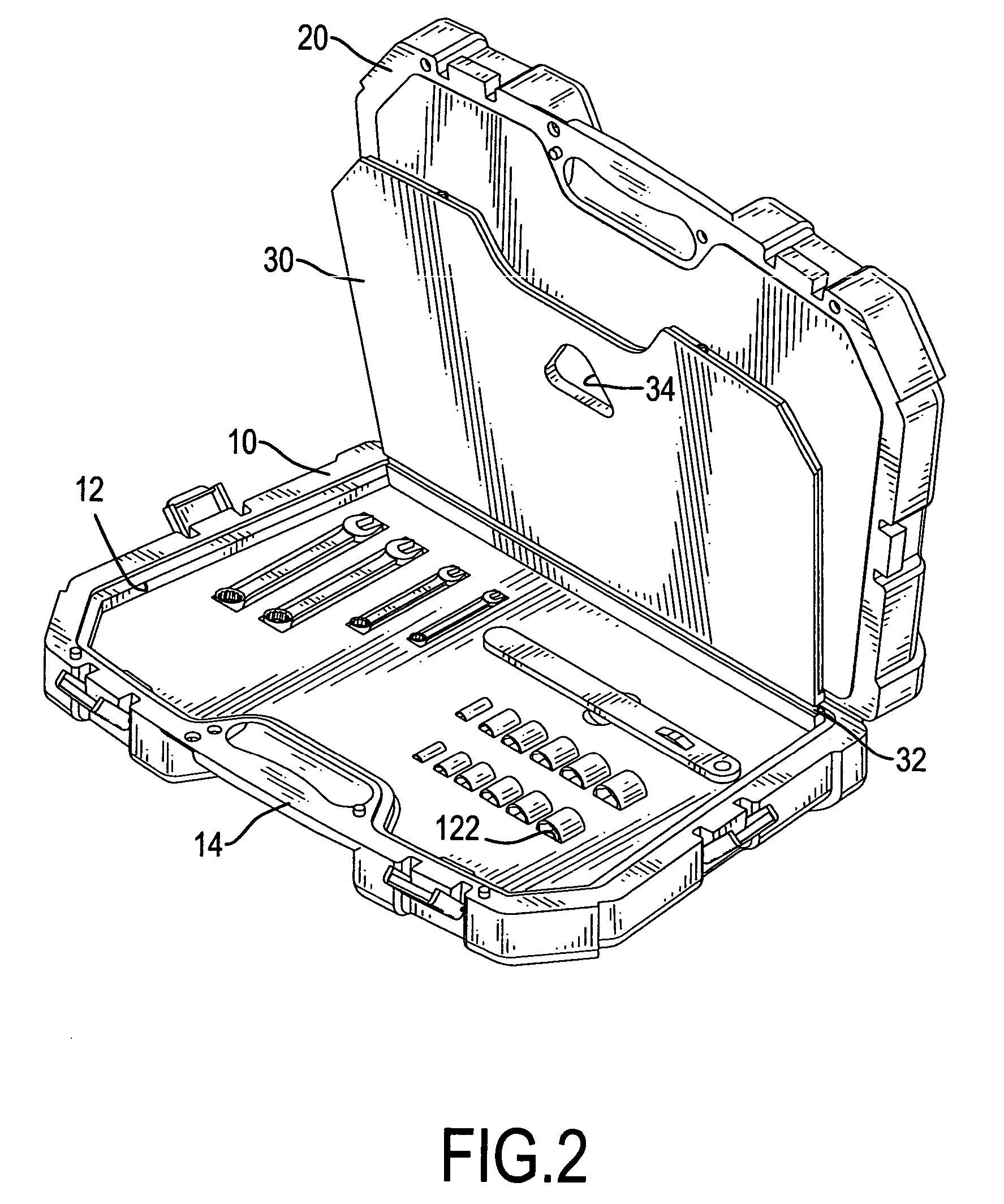

[0016] With reference to FIGS. 1 to 3, a tool case in accordance with the present invention comprises a body (10), a cover (20), a first baffle (30), a positioning device (not numbered). The body (10) has a top (not numbered), a recess (12), multiple cavities (122) and a handle (14). The recess (12) is defined in the top and has an inner surface (not numbered) and a bottom (not numbered). The cavities (122) are defined in the bottom of the recess (12) to hold tools (not numbered). the handle (14) is formed on the body (10) for a user to conveniently carry the tool case. The cover (20) is pivotally attached to the body (10).

[0017] The first baffle (30) is pivotally attached to the body (10) with a pivot pin (not numbered) and is selectively received in the recess (12). The first baffle (30) covers the cavities (122) in the body (10), has a board (not numbered), a resilient connector (32) and a hole (34). The board has edges (not numbered) and a thickness and is pivotally attached to ...

second embodiment

[0020] With reference to FIG. 4, the tool case in accordance with the present invention has a cover (20′) with a top (not numbered), a recess (not numbered), multiple cavities (not shown) and a handle (not numbered). The recess has a bottom and is defined in the top of the cover (20′). The multiple cavities (not shown) defined in the bottom of the recess to hold tools. The handle is formed on the cover and corresponds to the handle formed on the body. The cover is pivotally attached to the body at an edge away from the handle.

[0021] A second baffle (40) is pivotally attached to the cover (20′) with a pivot pin and is selectively received in the recess in the cover (20′). The second baffle (40) corresponds to the cavities in the cover (20′) to hold the tools in the cavities. The second baffle (40) has a structure the same as the first baffle (30) on the body (10) and comprises a board (not numbered), a resilient connector (not numbered) and a hole (not numbered). A second positioning...

third embodiment

[0022] With reference to FIG. 5, the tool case in accordance with the present invention has two body baffle (30′) pivotally attached to the body (10) and corresponding respectively to two groups of cavities (122) in the body (10). The body baffles (30′) may be made optionally of a transparent material. Accordingly, a person can see the tools stored in the cavities (122) through the body baffled (30′) and open the appropriate body baffle (30′) to retrieve a desired tool.

[0023] In an alternative embodiment of the tool case in accordance with the present invention, two cover baffles (not shown) can be mounted on the cover (20) when cavities (not shown) are defined in the cover (20) for storing tools.

[0024] With reference to FIG. 6, because the baffle (30″) can be held in position relative to the body (10′) to hold the tools in the cavities, the baffle (30″) can serve as a cover. Therefore, attaching a cover (20) to the body (10) as described in the first embodiment of the tool case is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com