Type B bulk bag with liner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

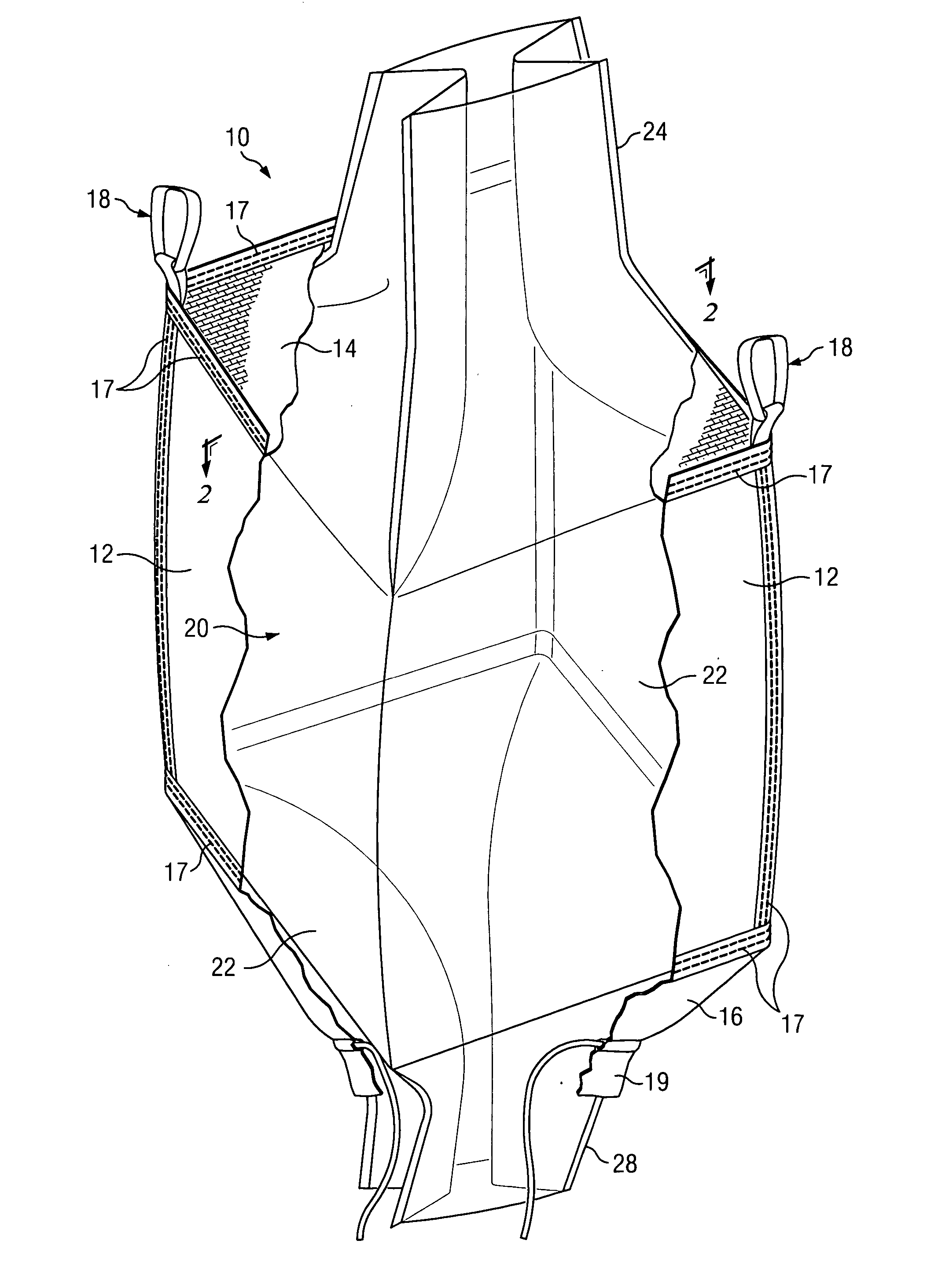

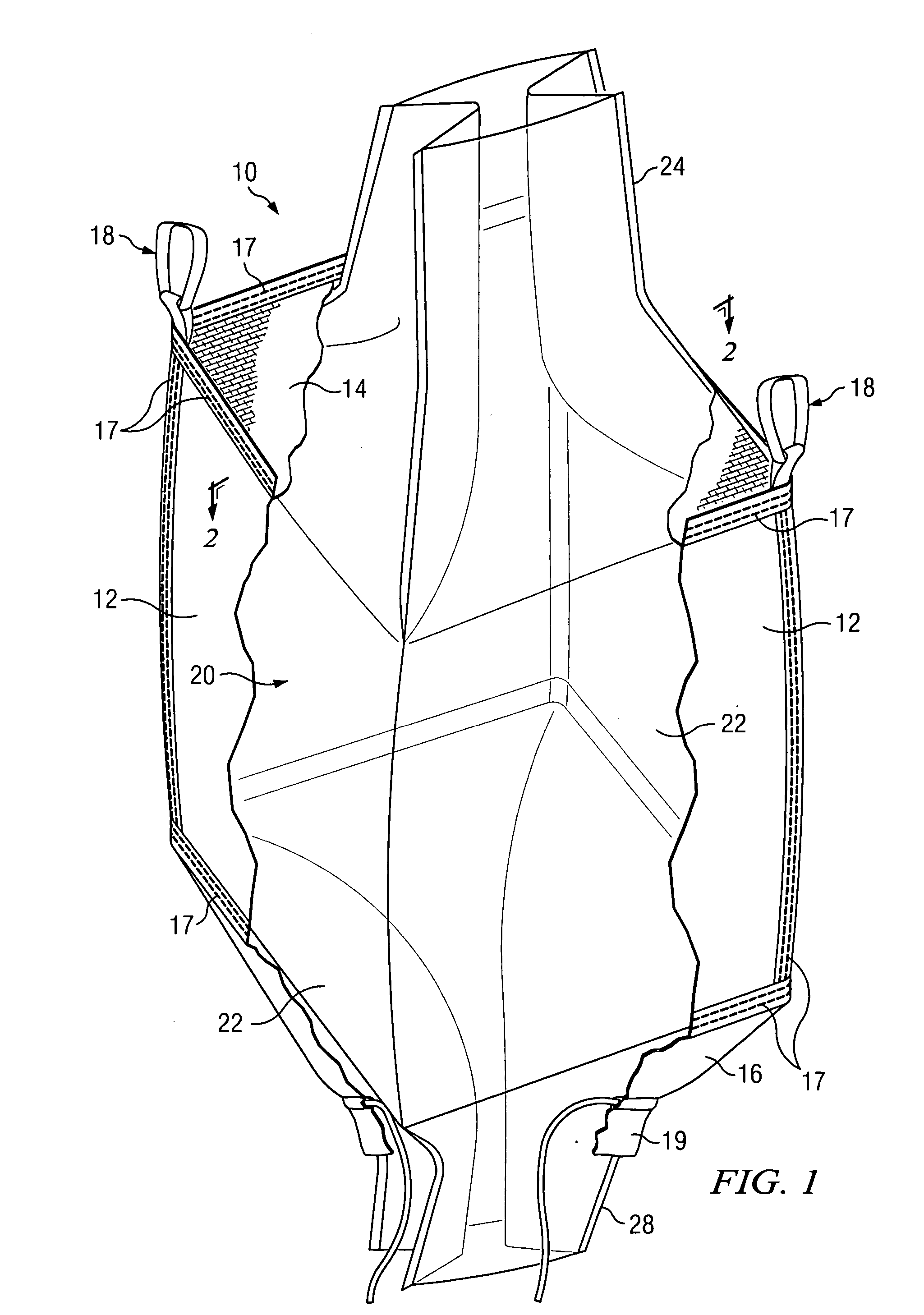

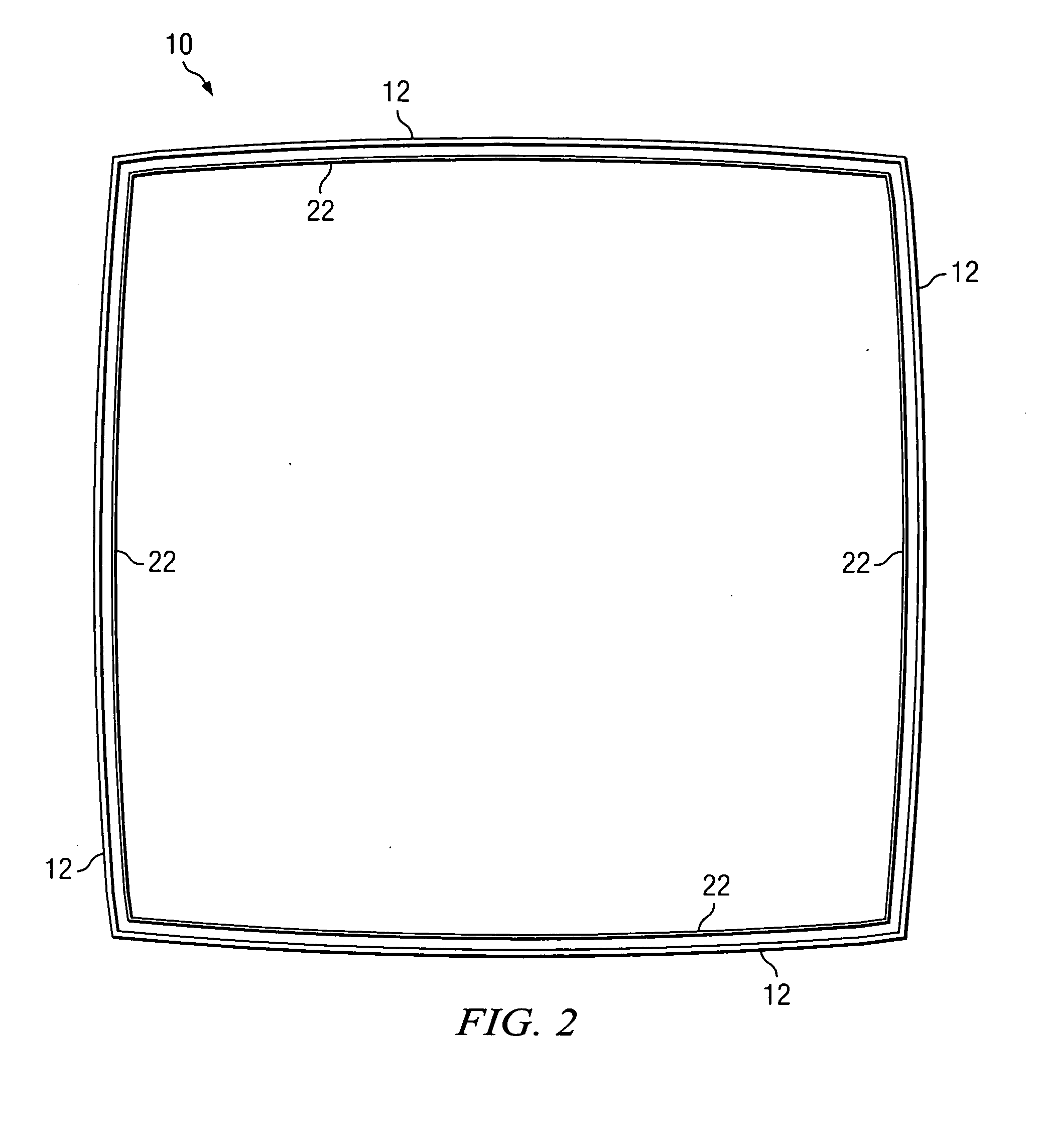

[0011] Referring now to the Drawings, and particularly to FIG. 1 thereof, there is shown a bulk bag 10 incorporating the present invention. The bulk bag 10 comprises four side walls 12, a top wall 14, and a bottom wall 16. However, as will be readily understood by those skilled in the art, the present invention is equally applicable to tubular bulk bags, U-panel bulk bags, and numerous other bulk bag constructions all of which are well known in the art.

[0012] The side walls 12, the top wall 14, and the bottom wall 16 comprising the bulk bag 10 are all formed from woven polypropylene fabric. More specifically, the side walls 12, the top wall 14, and the bottom wall 16 are formed from conventional 5 ounce per square yard uncoated woven polypropylene fabric. The side walls 12, the top wall 14, the bottom wall 16, and the other components of the bulk bag 10 are joined one to another by sewing along sew lines 17 in the conventional manner. Conventional lift loops 18 may be provided at t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mass | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com