Protective structure of disc packaging

a protective structure and disc technology, applied in the direction of record information storage, packaged goods type, instruments, etc., can solve problems such as damage to discs, and achieve the effects of reducing disc packaging costs, simplifying protective structures, and simplifying structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] To enable a further understanding of the structural features and contents of the invention, the brief description of the drawings below is followed by the detailed description of a preferred embodiment.

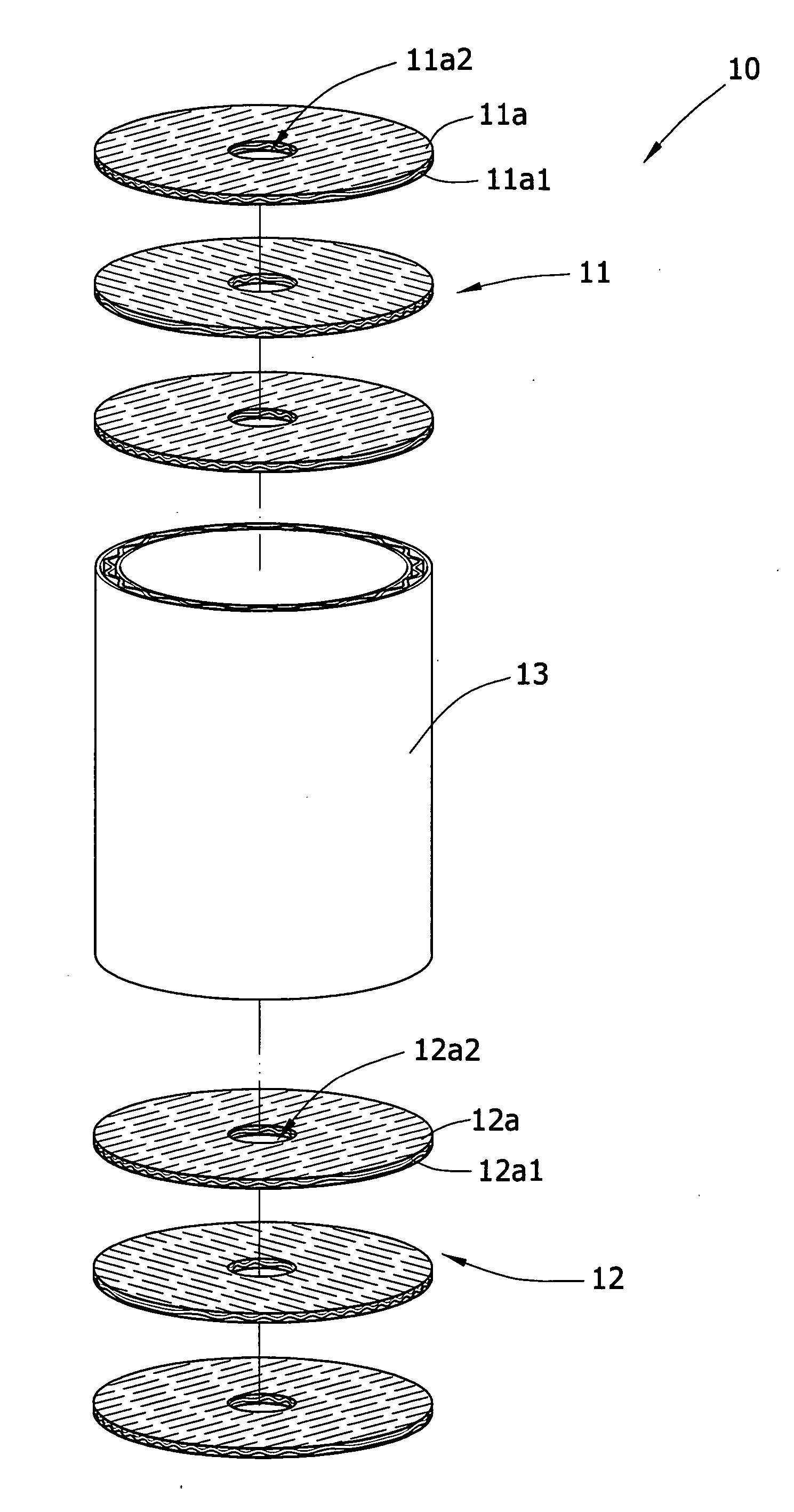

[0019] With reference to FIGS. 4, 5, 6 and 7, a protective structure 10 is composed of an upper lid 11, a lower lid 12 and a casing 13 placed on the top and the bottom sides and the perimeters of a pile of discs, wherein:

[0020] The upper and the lower lids 11 and 12 are respectively composed of at least two interlaced disc-shaped plates 11a and 12a, which are made of corrugated paper 11a1 or plastic corrugated sheet 12a1. When the upper and the lower disc-shaped plates 11a and 12a are disposed, the undulating buffer portions 11a1 and 12a1 are vertically stacked up, in addition, the sizes of the disc-shaped plates 11a and 12a are larger than those of the discs; moreover, the circle centers of said disc-shaped plates 11a and 12a set round holes each corresponding to the positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com