Cast-in-situ tongue-and-groove type outer wall post-cast strip protection structure and construction method

A technology of cast-in-place groove-and-groove protection structure, which is applied in infrastructure engineering, underwater structures, artificial islands, etc. It can solve the problems of waterproofing, backfilling, poor waterproofing effect, long waiting time, etc., and achieve waterproofing The effect is good, the safety hazard is small, and the protective structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

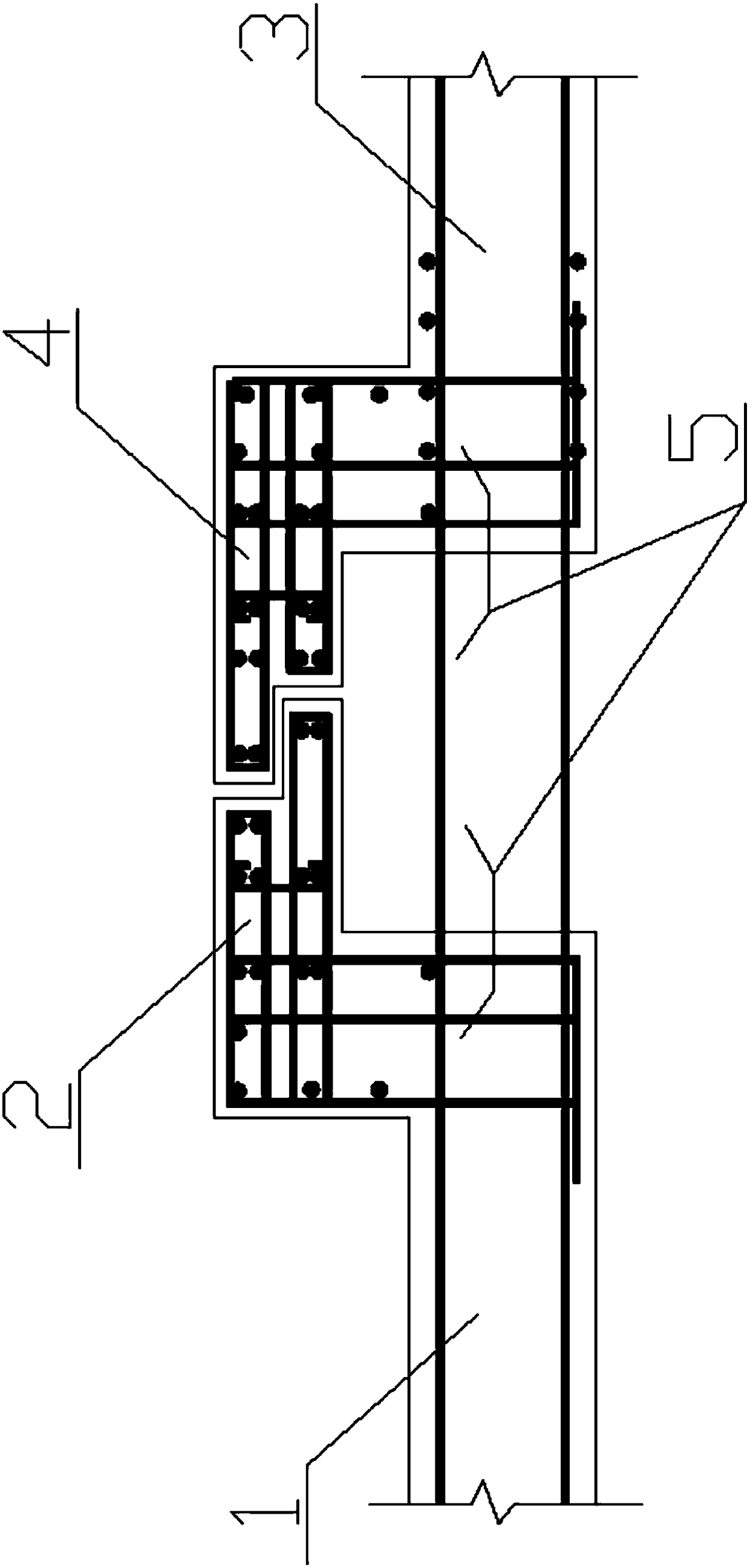

[0024] Such as figure 1 As shown, a cast-in-situ groove-and-groove outer wall post-cast belt protection structure of the present invention includes a left outer wall 10, a right outer wall 20, a left protective wall 30, a right protective wall 40 and a water-stop steel plate 50. The left outer wall The wall 10 and the right outer wall 20 are located on the same straight line, the ends of the two are separated and formed with a post-casting belt, the left protective wall 30 is fixedly connected to the end of the left outer wall 10, and the right protective wall 40 is connected to the end of the right outer wall 20 Fixed connection, the left protective wall 30 and the right protective wall 40 both extend to the same side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com