Vibratory concrete float

a technology of vibrating concrete and float, which is applied in the direction of portable power tools, roads, constructions, etc., can solve the problems of increasing finishing time, ineffectively reaching all the areas of the concrete surface, and cumbersome closing up the edges with a hand float, so as to reduce the finishing time and efficiently close up the concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following detailed description illustrates the invention by way of example and not by way of limitation. The description clearly enables one skilled in the art to make and use the invention, describes several embodiments, adaptations, variations, alternatives, and uses of the invention, including what is presently believed to be the best mode of carrying out the invention.

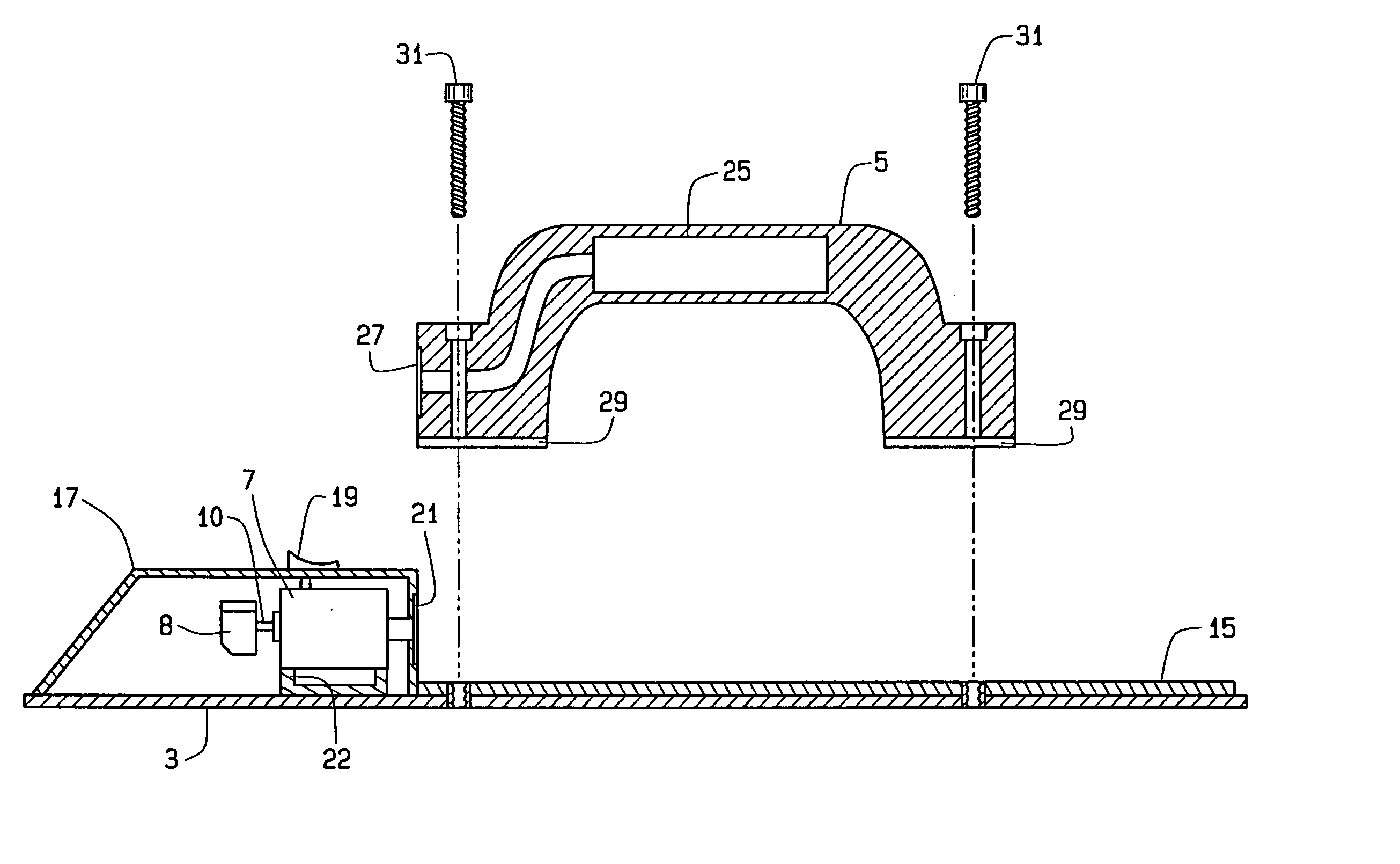

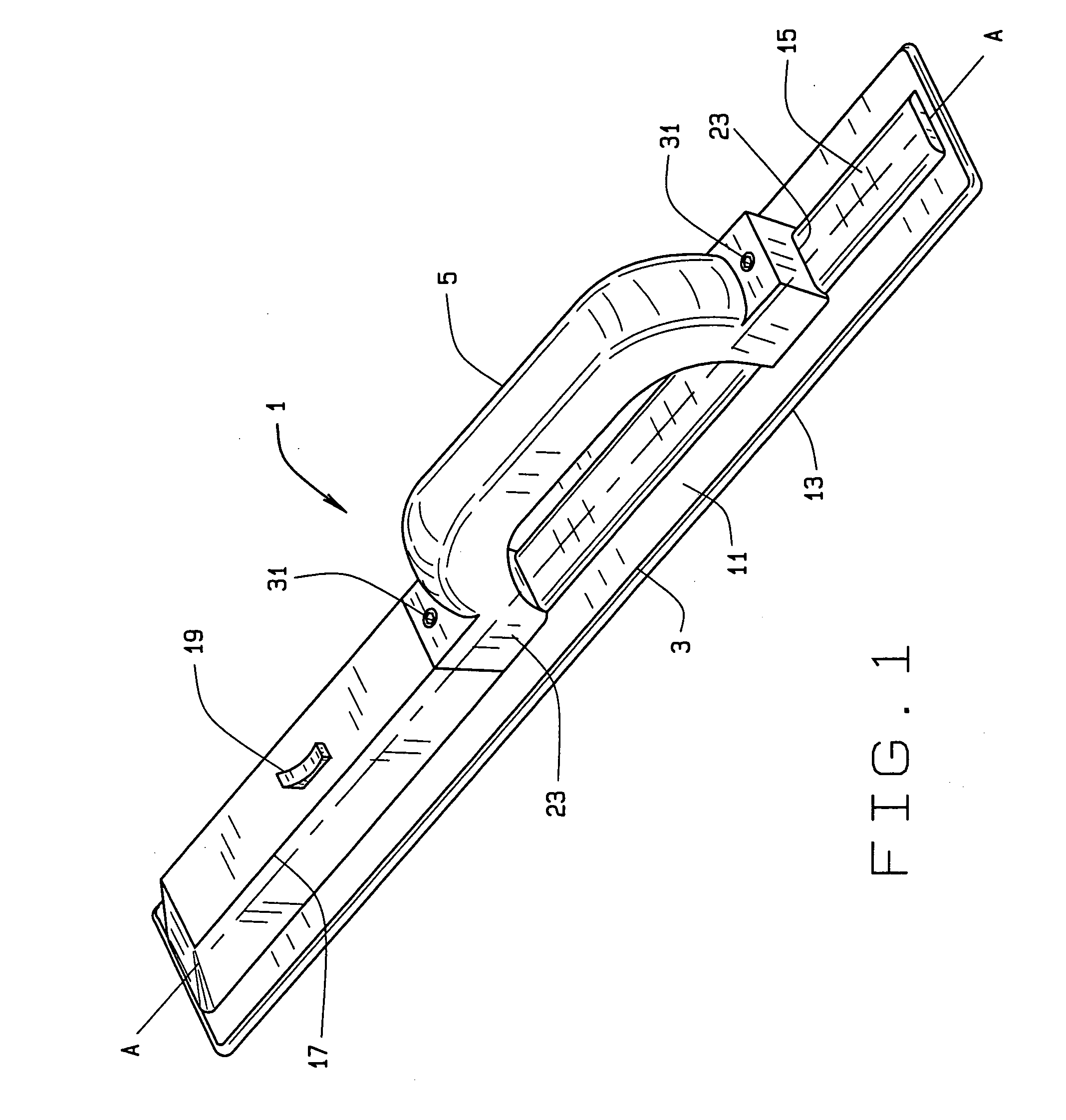

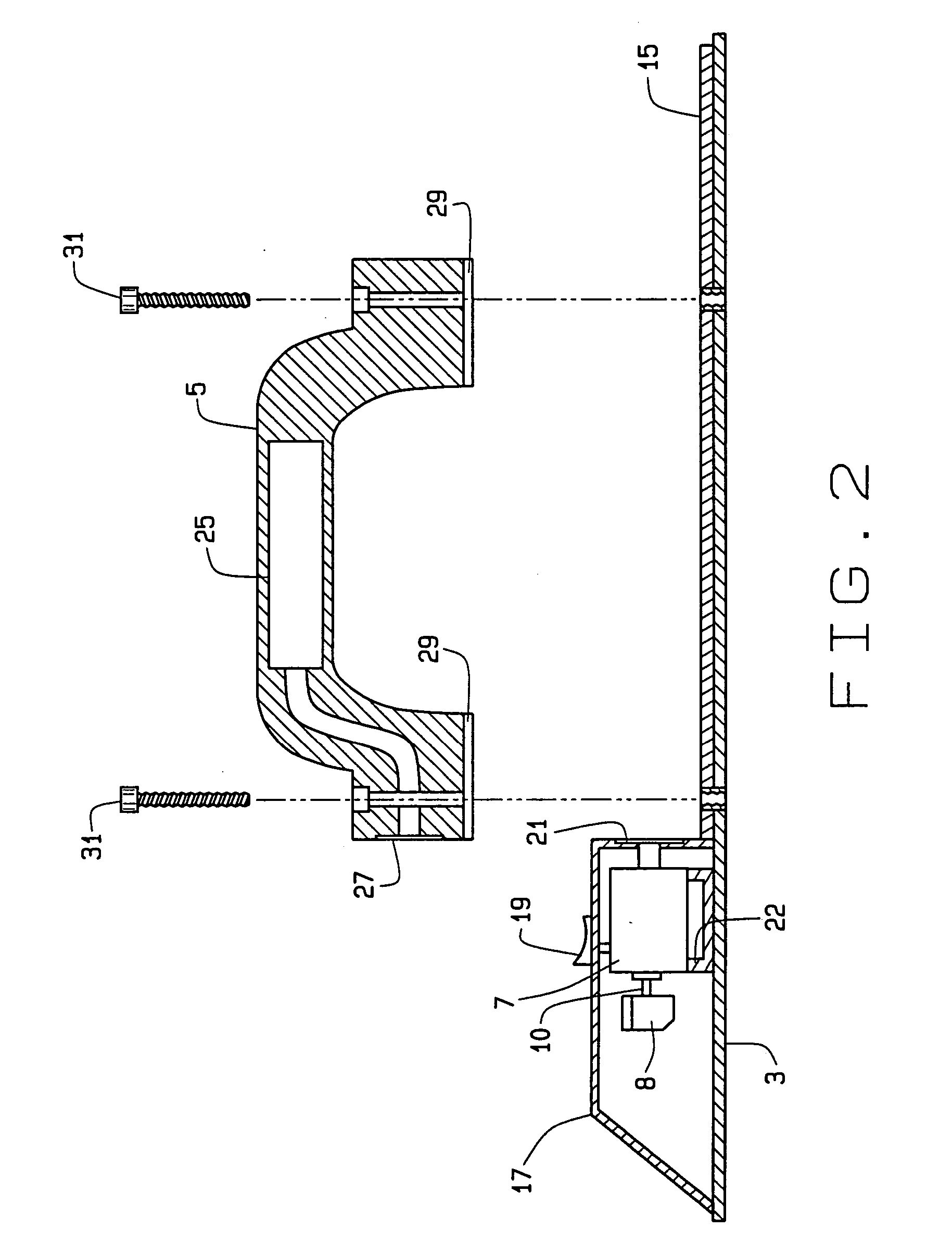

[0015] As shown in FIGS. 1-2, an embodiment of the present invention, generally referred to as a vibratory concrete float 1, includes a body 3 secured to a removable handle 5 and a vibrator motor 7.

[0016] The body 3 is a generally rectangular plate having a bottom surface 9, a top surface 11, and a peripheral edge 13. In one embodiment, the body or plate 3 is preferably made of magnesium, but other materials such as aluminum, steel, plastic, or even wood may be used. For example, a magnesium plate 3 about 3 inches wide and about 16 inches long having a thickness of about ⅜ inch has worked well. A raise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com