Universal pneumatic-snake apparatus & method

a technology of pneumatic snakes and universal cylinders, which is applied in water installations, lavatory sanities, construction, etc., can solve the problems of adding more of a dirty water mess, and achieve the effects of convenient cutting through and loosening, effective and efficient, and adaptable and convenien

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

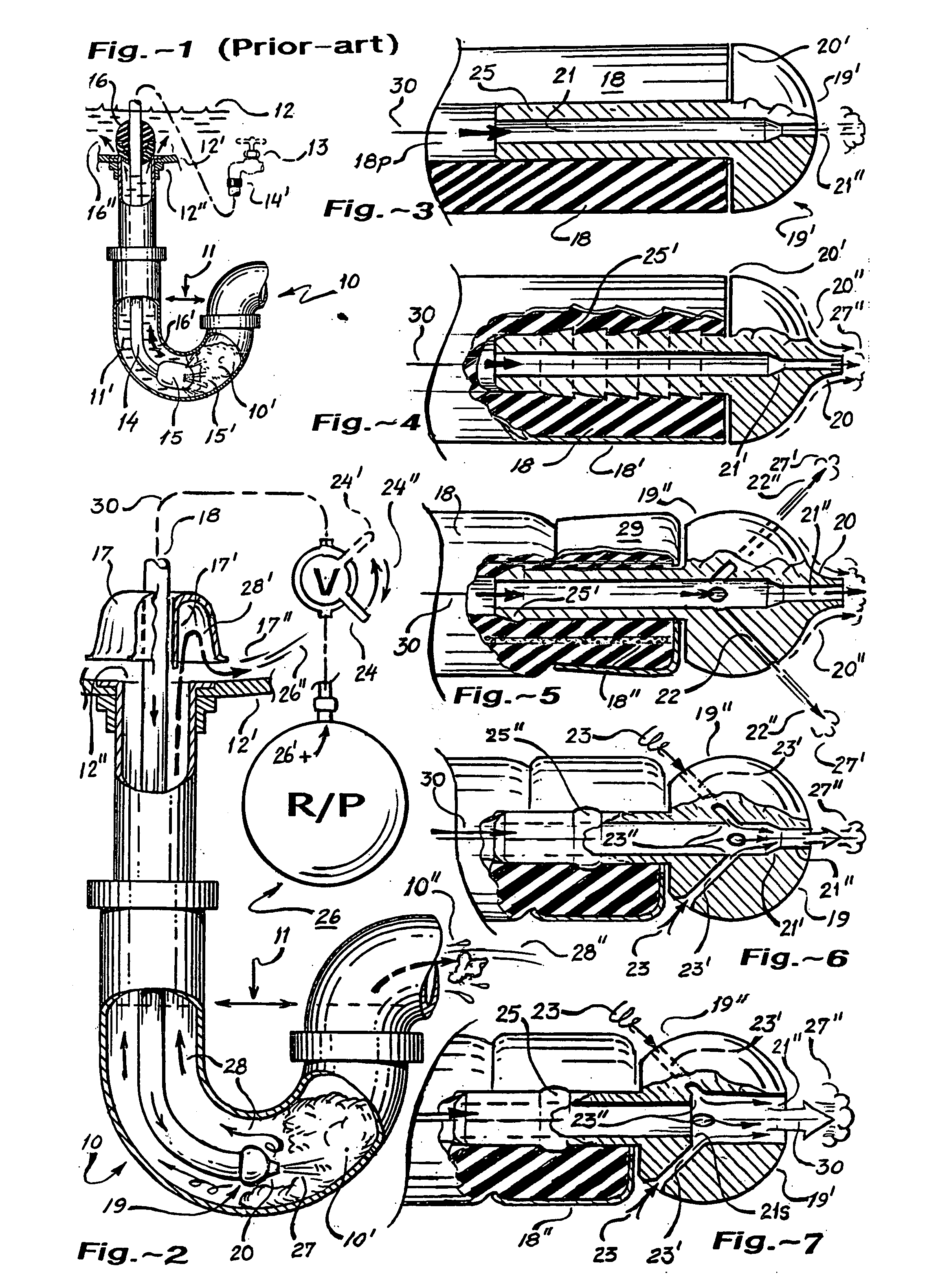

[0034] The foregoing and still other objects of this invention will become fully apparent, along with various advantages and features of novelty residing in the present embodiments, from study of the following description of the variant generic species embodiments and study of the ensuing description of these embodiments. Wherein indicia of reference are shown to match related matter stated in the text, as well as the claims section annexed hereto; and accordingly, a better understanding of the invention and the variant uses is intended, by reference to the drawings, which are considered as primarily exemplary and not to be therefore construed as restrictive in nature; wherein:

[0035]FIG. 1, is a semi-diagrammatic side / elevation-view of the “prior-art” hydraulic-snake apparatus and system, serving to demonstrate the problems inherent in the use of water as the jet-thrust blasting medium; thereby exacerbating the water-flooding situation;

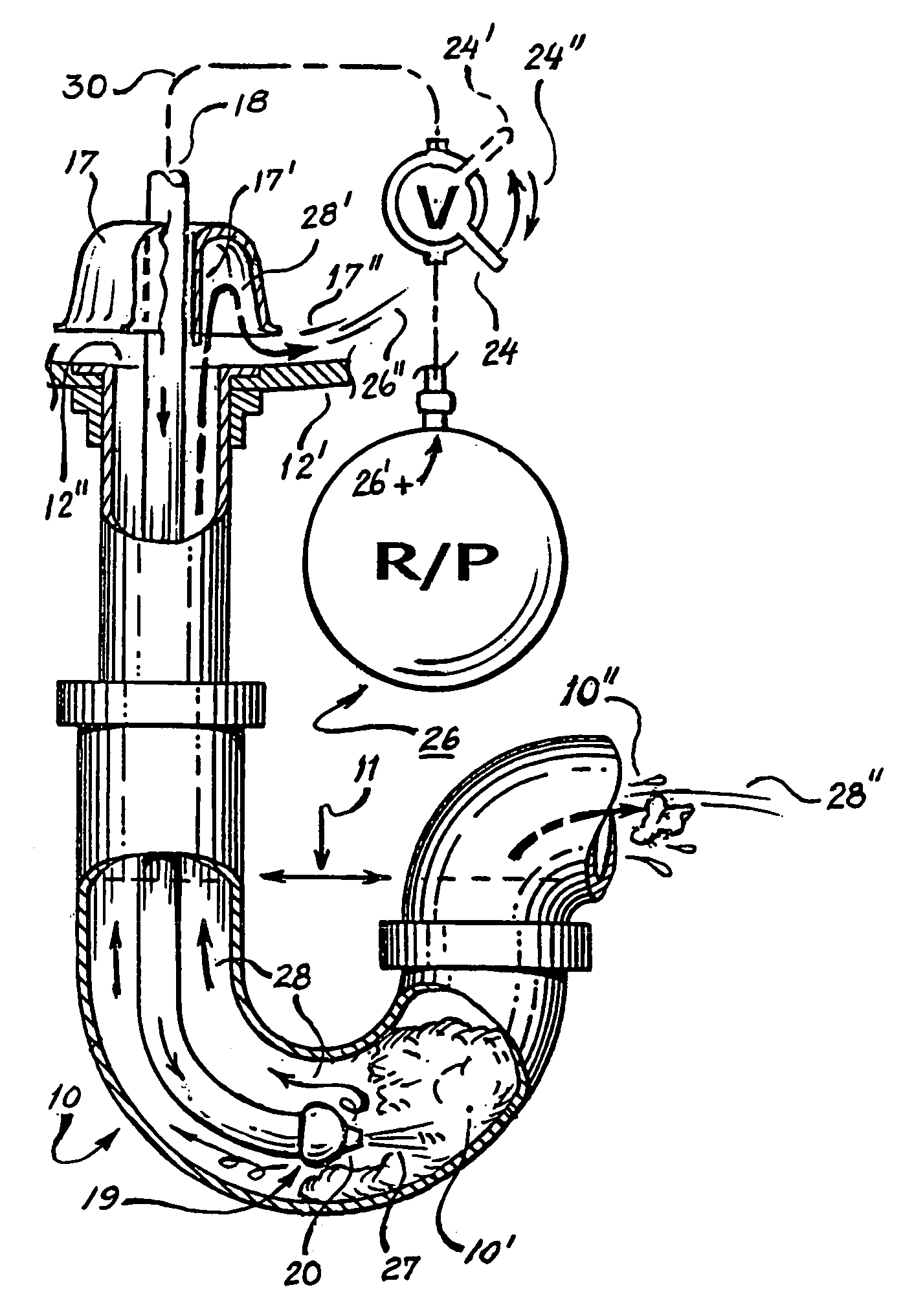

[0036]FIG. 2, is a semi-diagrammatic side / ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com