High profile composition shingles for roofs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

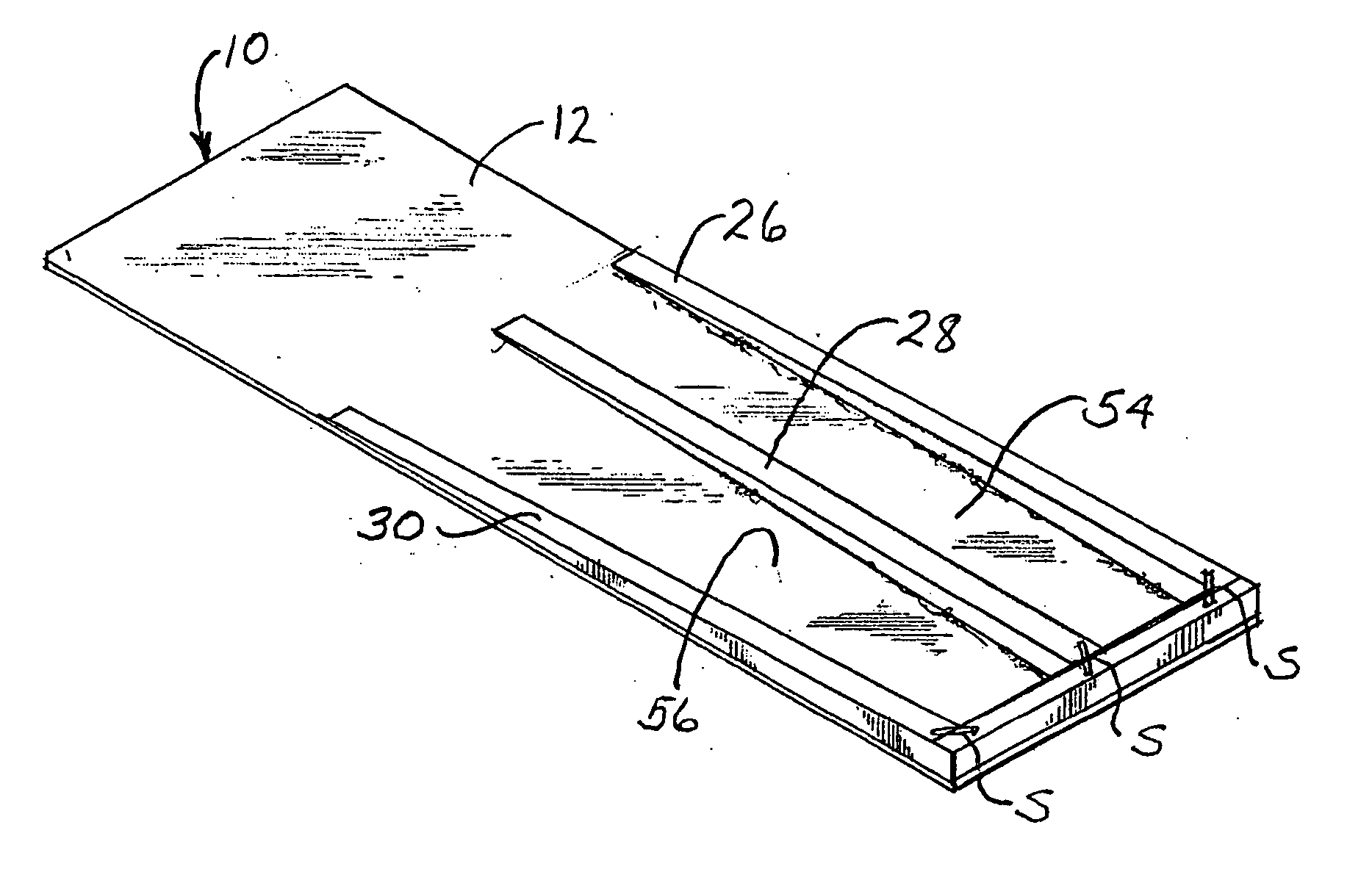

Image

Examples

Embodiment Construction

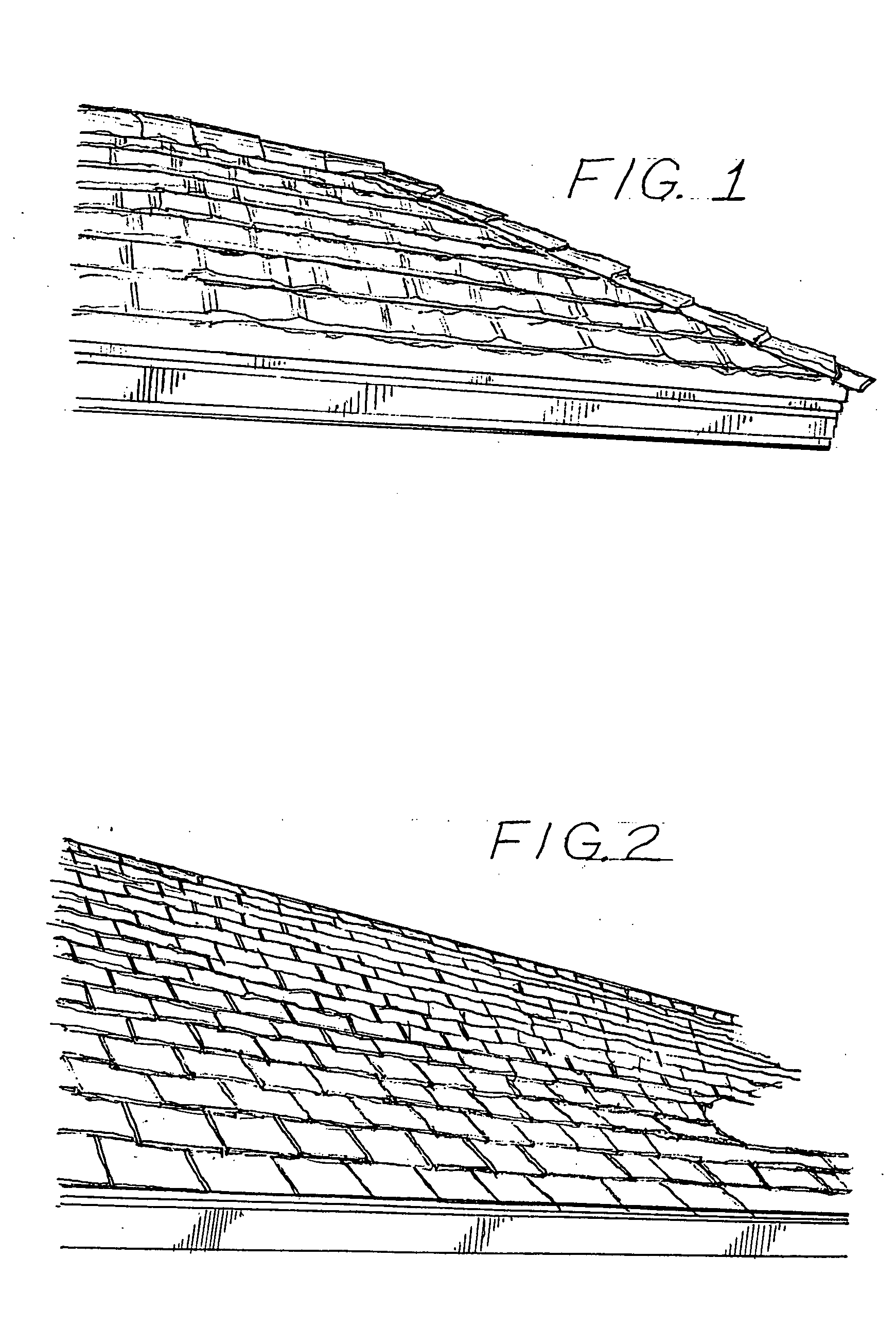

[0036]FIGS. 1 and 2 of this application are perspective views of two types of existing roofing materials which are man-made and are designed to simulate, in the case of FIG. 1, wood shake shingles marked by their irregularity and gaps that produce deep, regular shadows, as are illustrated in FIG. 1. The shingles of FIG. 1 are of cementitious material, which is significantly heavier than normal wood shakes but do provide effective roofing with no danger of flammability, as is a real problem for wood shakes.

[0037] In FIG. 2, simulated slate shingles made of cementitious material are shown having a depth noted by the shadows, even in the face of direct sunlight. This roof is greater in cost than normal composition roofs and comparable to some slate roofs.

[0038] Both the roofs in FIGS. 1 and 2 tend to be heavier than most composition roofs but do provide a reasonable replica of the appearance of wood shakes or slate roofs.

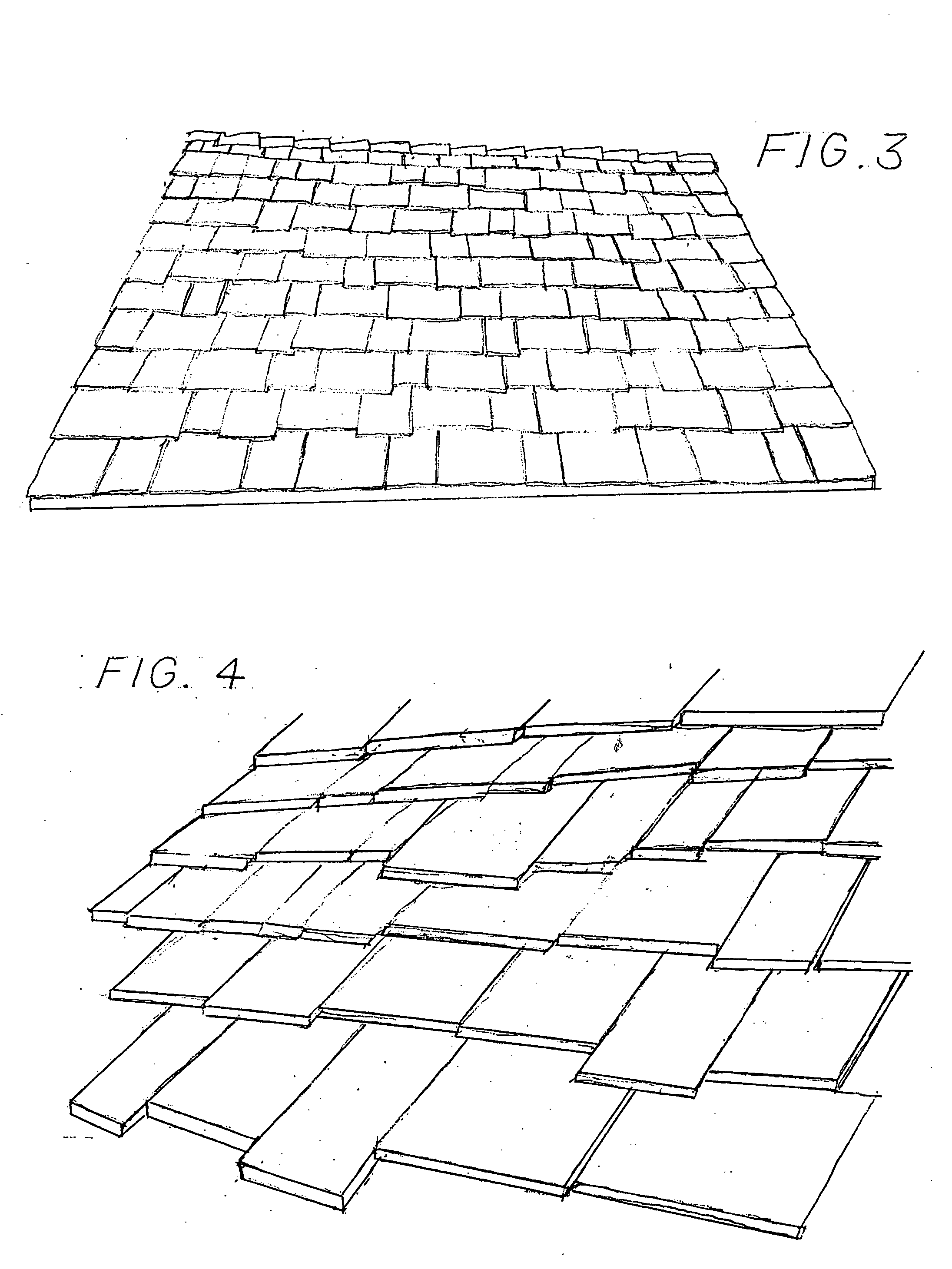

[0039]FIG. 3 shows a sample roof of this invention made totall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com