Material mover having a fluid film reservoir

a material mover and fluid film technology, applied in the direction of wheelchair/patient conveyance, load securing, transportation items, etc., can solve the problems of patients who cannot by themselves sit up or move, it is difficult to move easily and practically an object, and the range of applications desiring an improved transportation device is vast, so as to facilitate keeping the patient centered, enhance safety, and widen the effect of width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

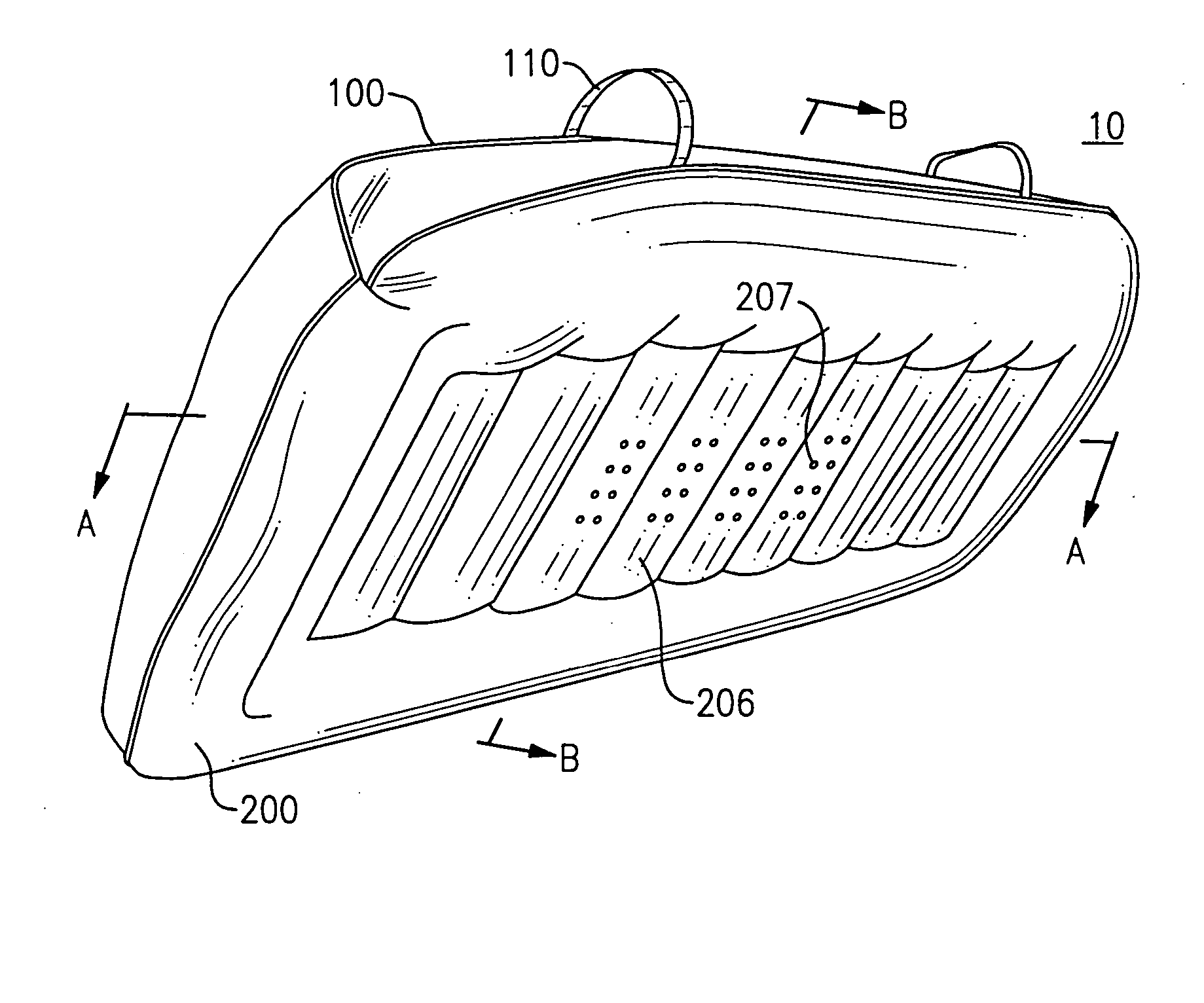

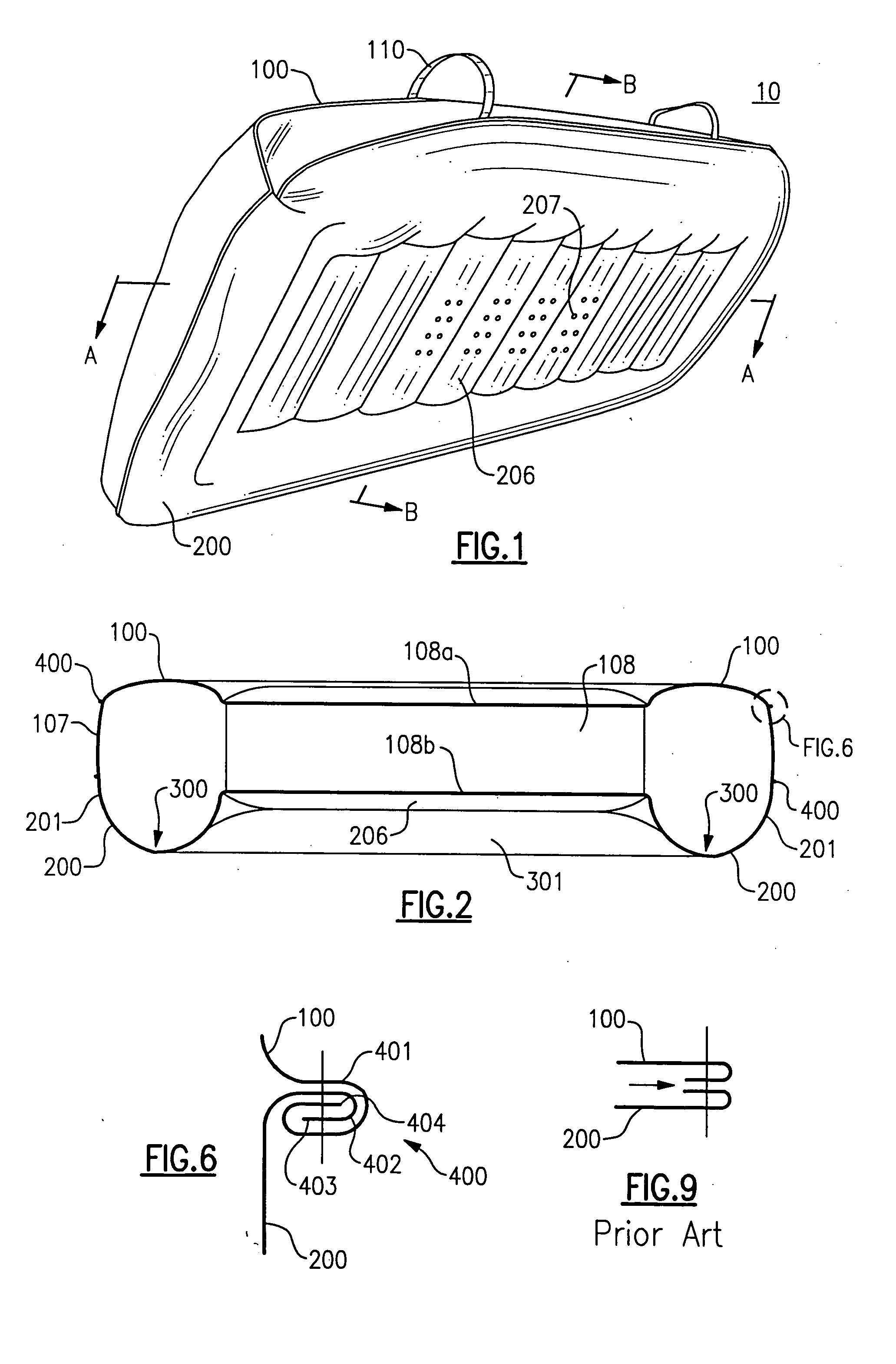

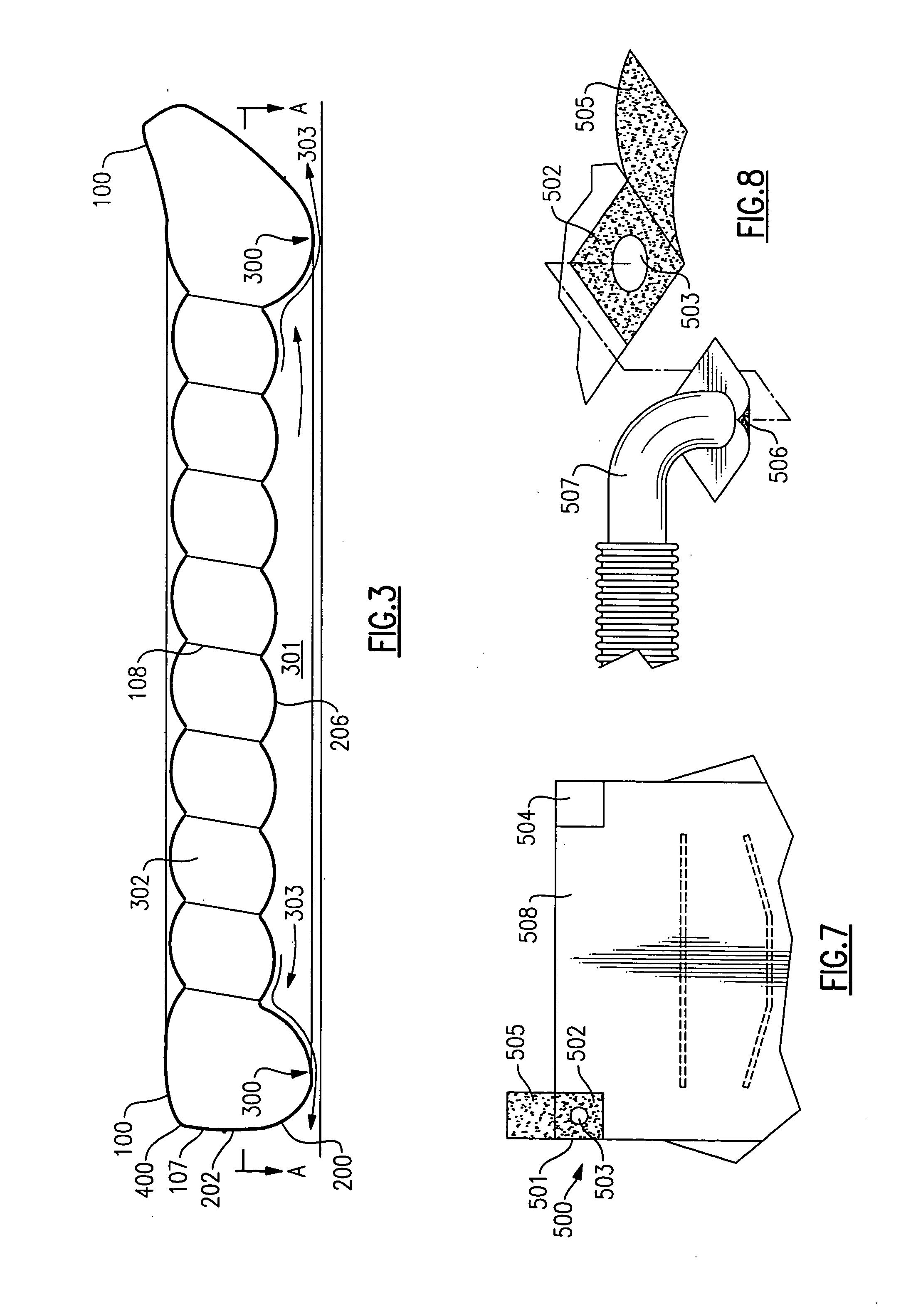

[0043]FIGS. 1-3 show a material mover 10 that includes a plenum chamber 302 (seen more clearly in FIG. 3), from which a fluid, such as air, oil, water or the like, exits through a plurality of orifices 207 to produce a fluid film 303 underneath at least a central portion of material mover 10. The plenum chamber 302 is defined by substantially rectangular top and bottom sheets 100 and 200, respectively, and perimeter side walls 107 connecting portions of the top and bottom sheets to one another.

[0044]FIGS. 4 and 5 show that portions of longitudinal edges 102 of top sheet 100 are connected to perimeter side walls 107, which, in turn, are connected to portions of longitudinal edges 201 of bottom sheet 200. The perimeter side walls 107 extend substantially the entire longitudinal length of lower and middle regions 106 and 105, respectively, of top sheet 100, and lower and middle regions 203 and 204, respectively, of bottom sheet 200. Lateral edges 103 are located in upper region 104 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com