Medical vacuum aspiration device

a vacuum aspiration and medical technology, applied in the direction of suction devices, intravenous devices, suction drainage containers, etc., can solve the problems of difficult cleaning and sterilization of mvas, parts are easily misplaced or lost when disassembled, and the material chosen for the components of mva may be susceptible to degradation and/or damage, etc., to achieve convenient cleaning and sterilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

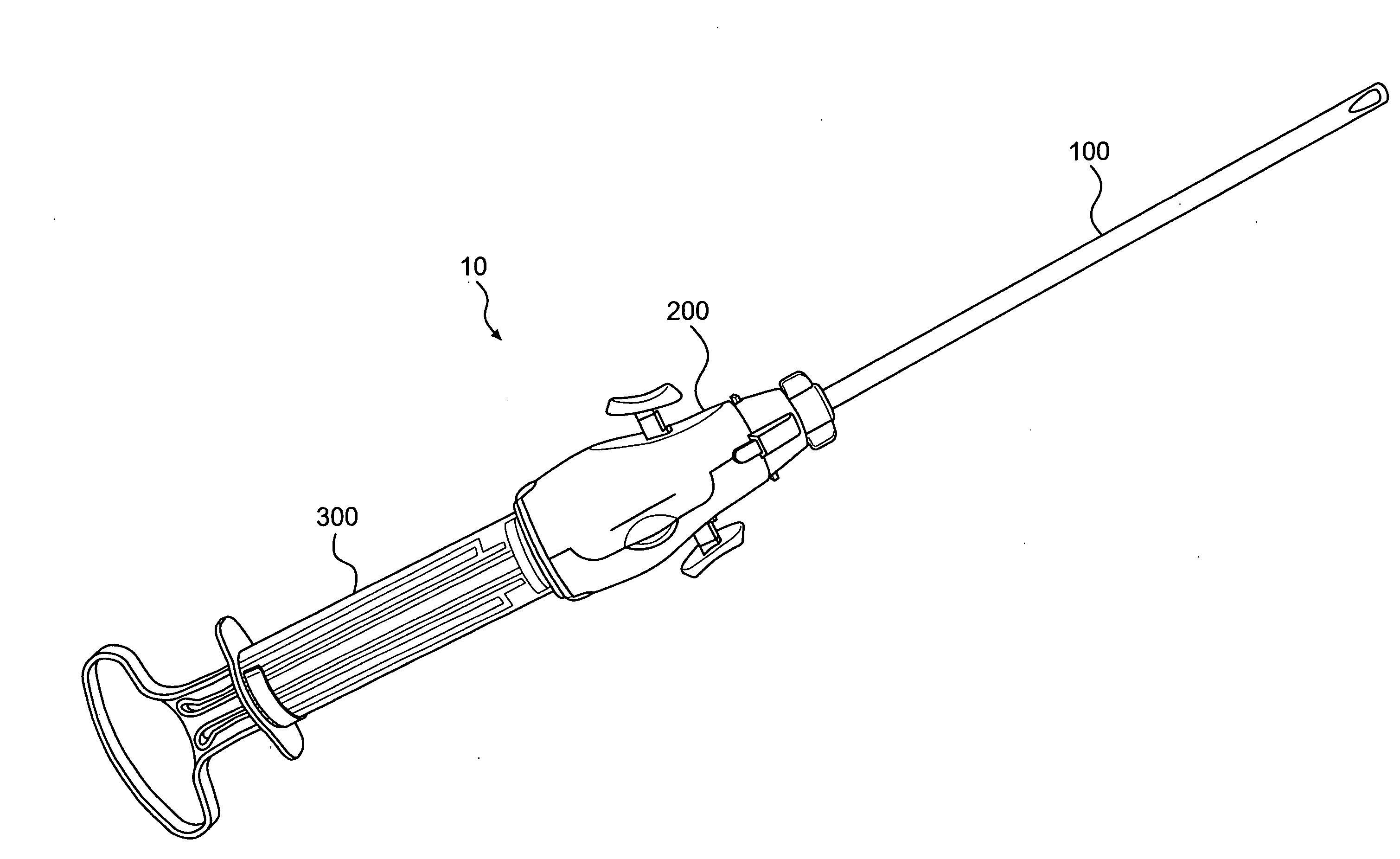

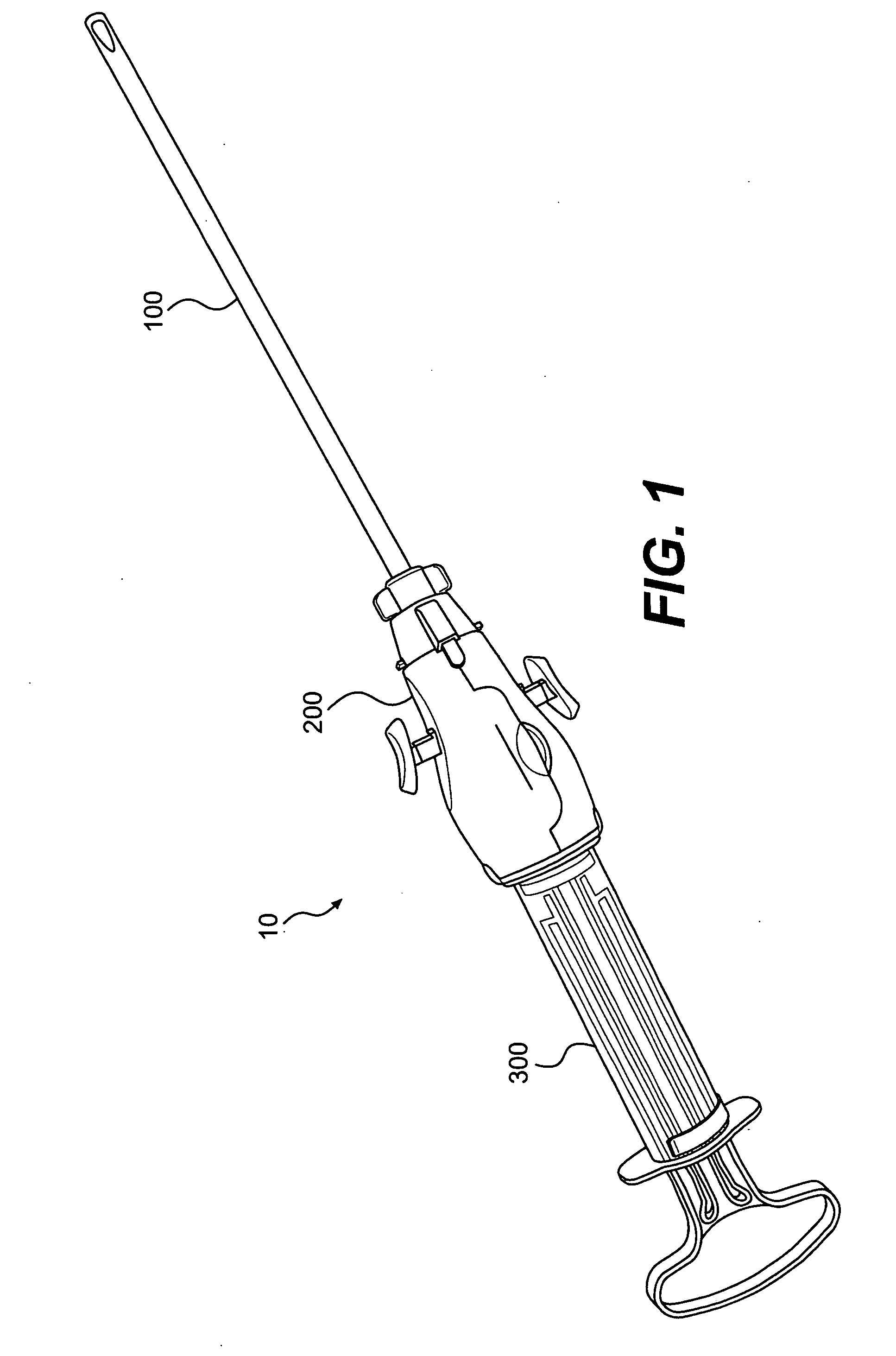

[0026]FIG. 1 illustrates an exemplary embodiment of a medical vacuum aspiration device (MVA) 10. The MVA 10 may include a cannula 100, a valve 200, and an aspirator cylinder 300. The cannula 100 removably connects to a first opening of valve 200 and the aspirator cylinder 300 removably connects to a second opening of the valve 200. The valve 200 opens and closes fluid communication between the cannula 100 and the aspirator cylinder 300.

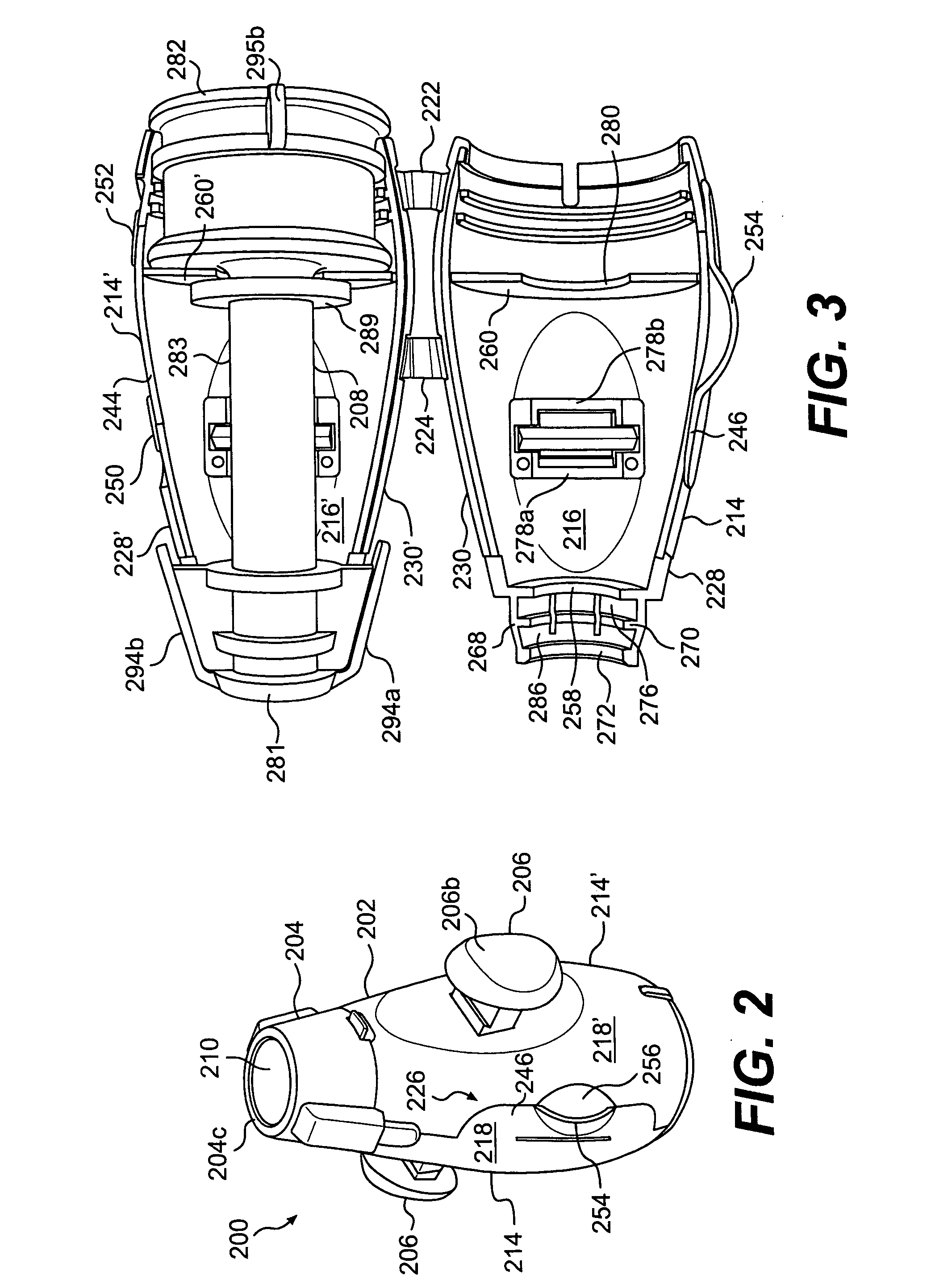

[0027] Referring to FIGS. 2 and 3, the valve 200 may include a housing 202, a cap 204, buttons 206, and a fluid conduit 208. The housing 202 includes first and second fluid openings 210, 212 into which the cannula 100 and the aspirator cylinder 300, respectively, are inserted. The housing 202 can be opened to permit access to and removal of the fluid conduit 208. As shown in FIG. 3, an interior of housing 202 receives at least part of the fluid conduit 208. According to one embodiment, each end of the fluid conduit 208 extends outward beyond the resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com