Skate boot

a technology for skate boots and boot soles, applied in footwear, domestic applications, other domestic objects, etc., can solve the problems of long and complex manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

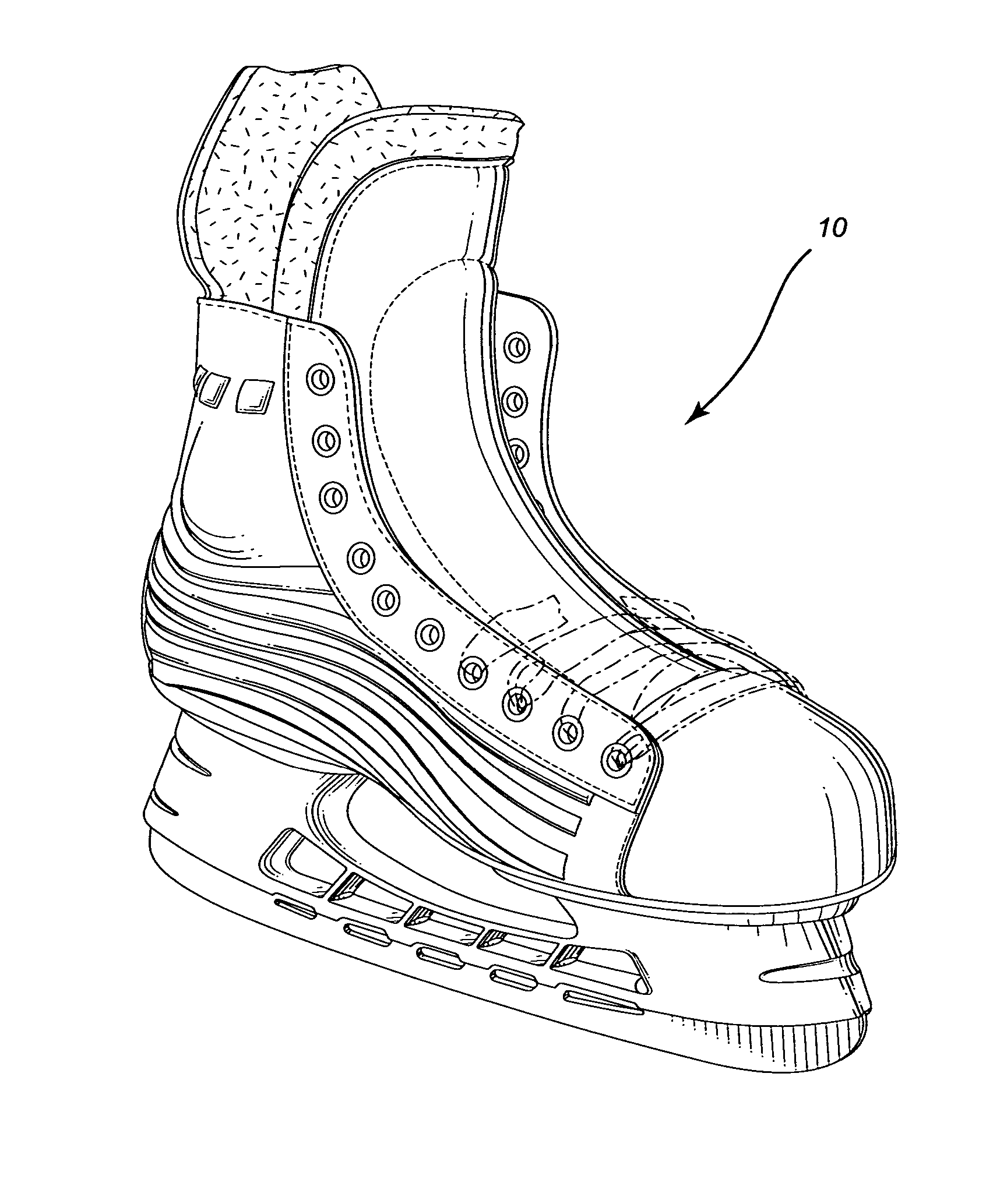

[0031] A skate boot manufactured in accordance with the present invention is illustrated generally by reference numeral 10 in FIG. 13.

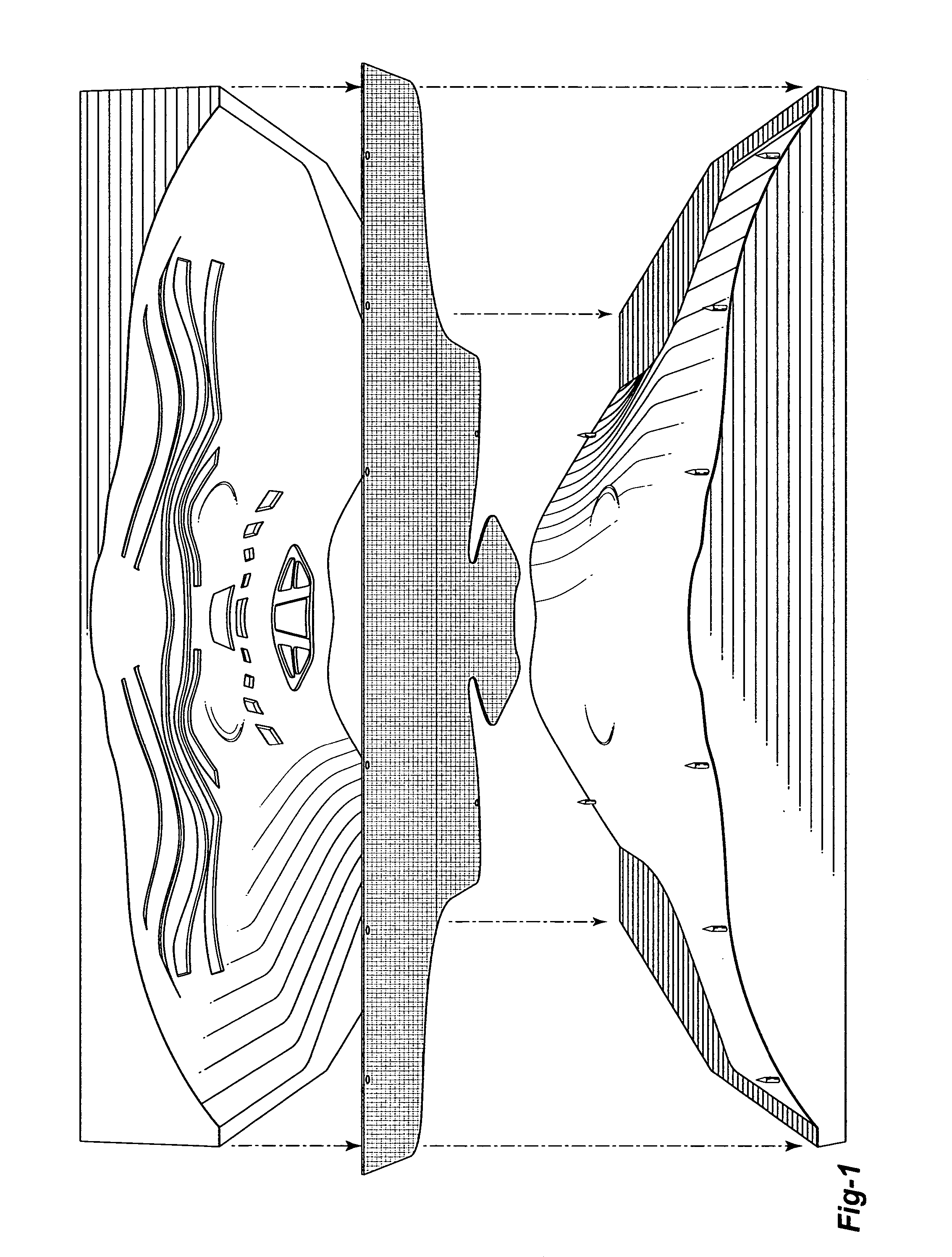

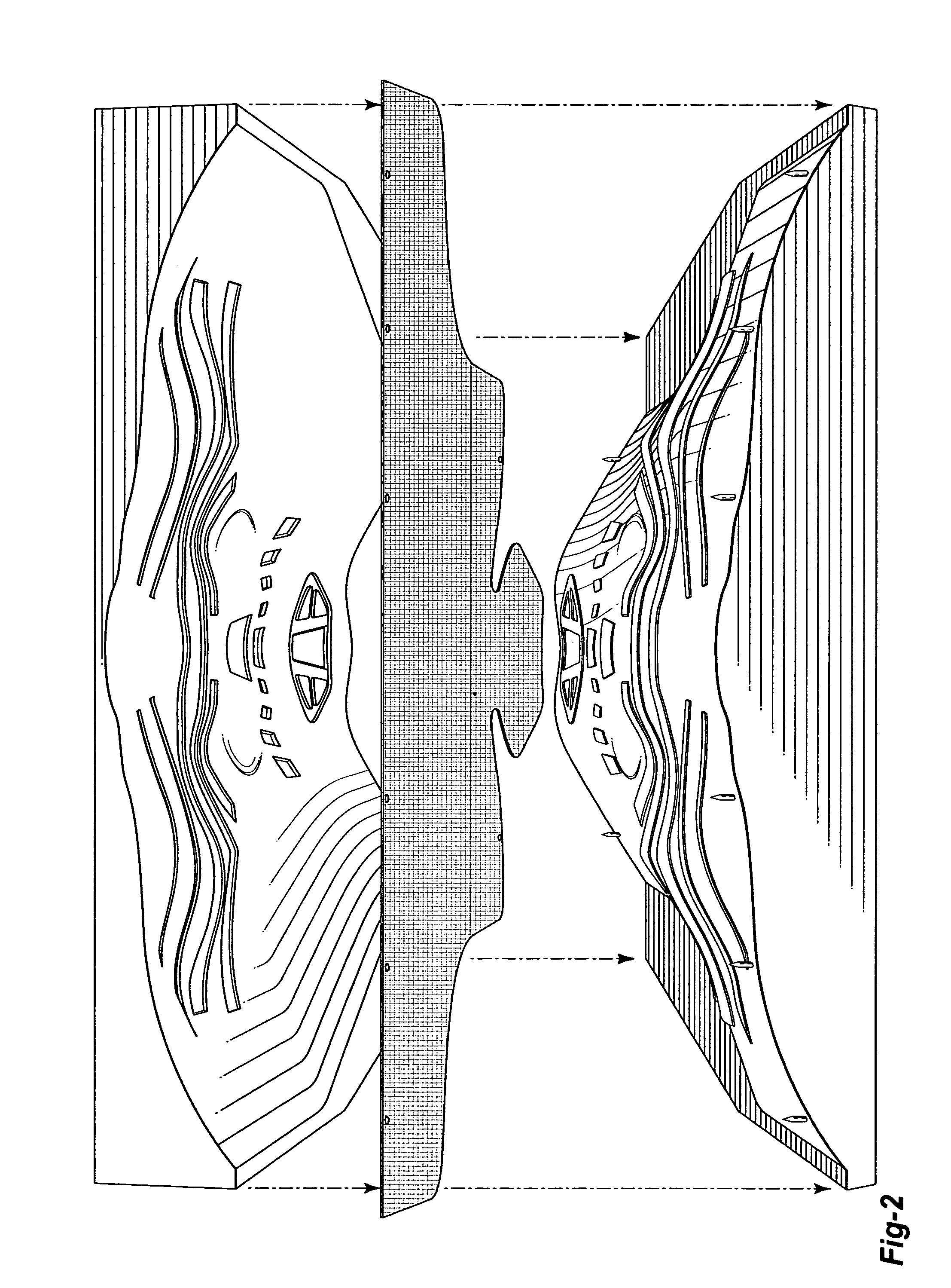

[0032] Referring to FIG. 11, skate boot 10 comprises an upper 12 for enclosing a human foot. Upper 12 comprises an outer shell 14 and an inner lining 16 mounted inside outer shell 14. Outer shell 14 illustrated in FIGS. 5 to 11 is for use in a skate boot for a right foot.

[0033] Outer shell 14 is molded of synthetic material. More particularly, outer shell 14 is made by thermo-pressured molding of a suitable thermoforming material initially in uniform thickness sheet form such as a pre-cut sheet having a desired contour, the sheet being made of thermoforming materials such as those sold under the trade-mark MEGABIX® (a core of extruded SURLYN®, a backing of SONTARA® and a hot melt coating; thickness of 0.95 mm), FORMO500® (non woven polyester with a core of extruded polyolefinic, stiffening layers of synthetic latex on each side and an ethylene vinyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com