Colored contact lens having very natural appearance

a contact lens and very natural technology, applied in the field of colored contact lenses, can solve the problems of lens not reaching commercial success, unnatural appearance of lens,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

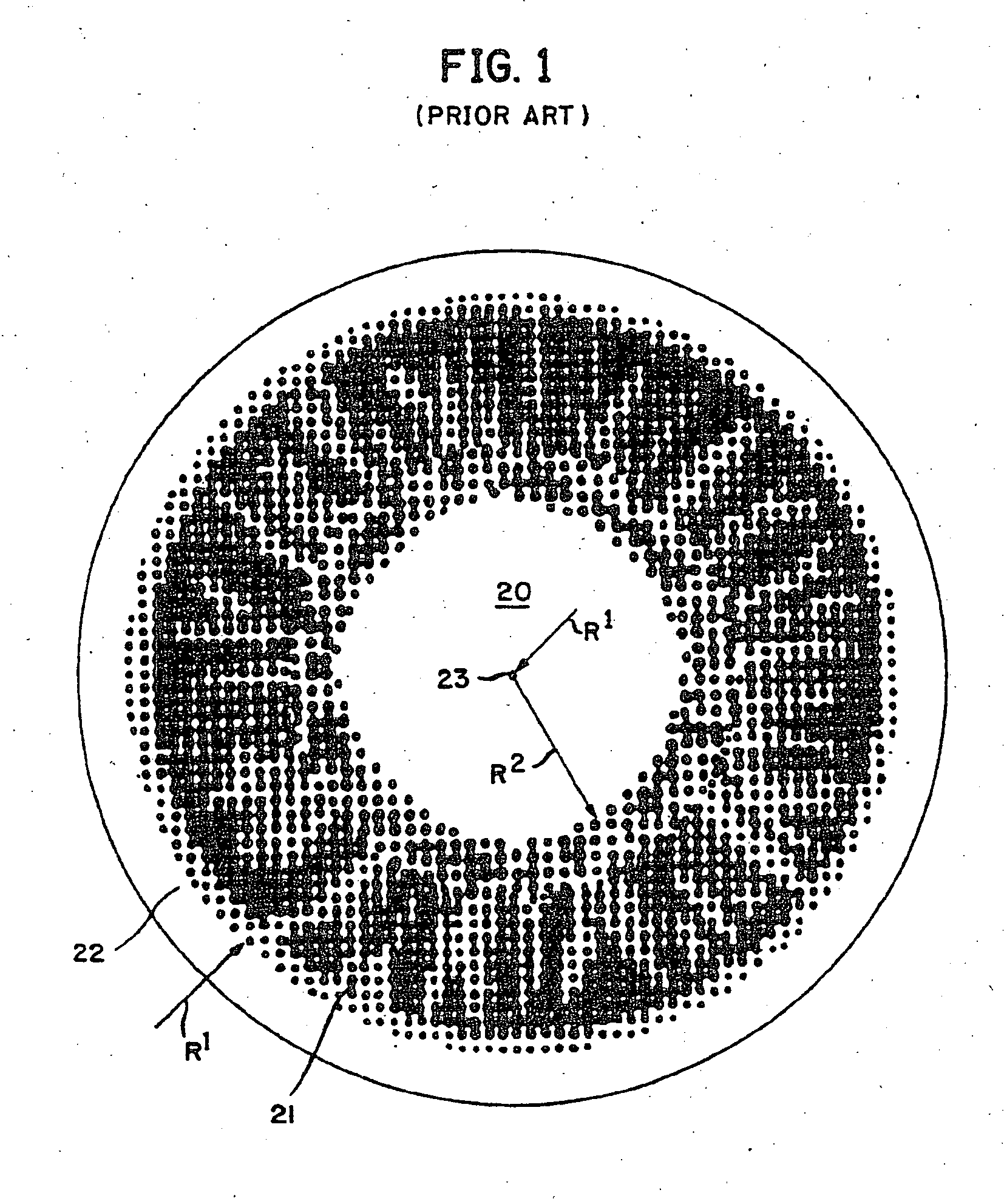

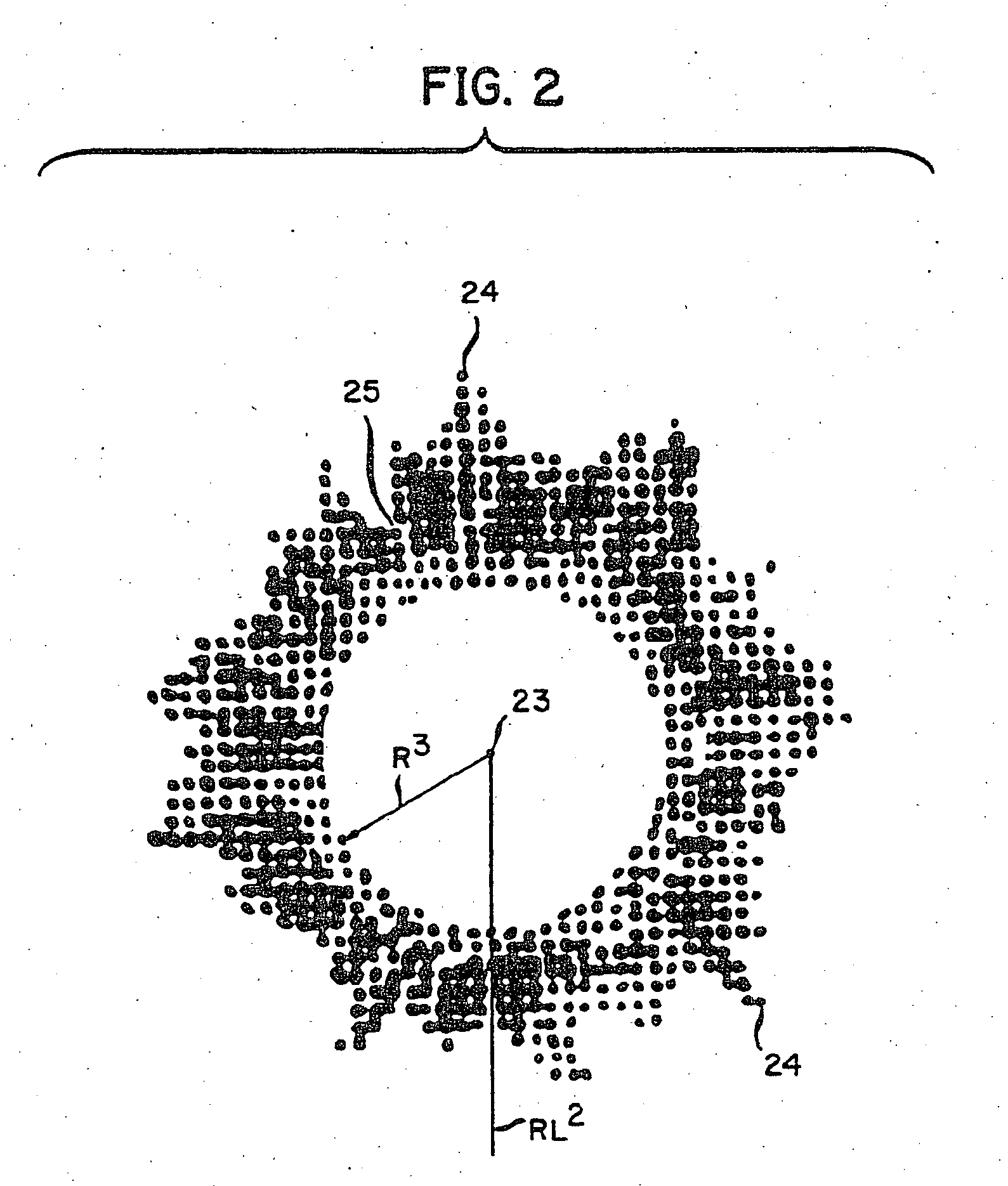

[0033] A hydrophilic lens made of hydroxyethyl methacrylate, ethoxy ethyl methacrylate, and methacrylic acid as shown in U.S. Pat. No. 4,668,240 is printed on its front, convex side with ink of a first shade containing pigment, binding polymer made from the same monomers used to form the lens, hexamethylene diisocyanate and solvent. The printed pattern is shown in FIG. 1. It covers most of the iris section, having an annular form, with an outer radius R1 of about 5.2 mm and an inner radius R2 of about 2.2 mm. After the ink has cured, the first pattern is overprinted with the pattern shown in FIG. 2 having a different shade than the pattern of FIG. 1. To accomplish this second printing, it is highly preferable to have the centers 23 of the patterns overlap. However, it is not necessary to rotationally align the patterns of FIGS. 1 and 2. That is, after the FIG. 1 pattern is printed on the lens, the rotation of the lens or the pad used in printing the pattern of FIG. 2 about lens cent...

example 2

[0044] A contact lens is printed first with the pattern of FIG. 3 and then with the pattern of FIG. 2 in a second shade. When using these two patterns, centers 23 of both patterns are in alignment and in addition the patterns are rotationally aligned so that radial lines RL1 and RL2 coincide. The following color combinations are currently preferred:

EXAMPLEFIG. 3 PATTERNFIG. 2 PATTERN2AInk No. 1 (Blue)Ink No. 2 (Hazel)2BInk No. 3 (Green)Ink No. 2 (Hazel)2CInk No. 4 (Brown)Ink No. 5 (Yellow Brown)2DInk No. 1 (Blue)Ink No. 6 (Misty Gray)2EInk No. 6 (Misty Gray)Ink No. 7 (Dark Gray)

EXAMPLE 3

[0045] Contact lenses are printed with the pattern of FIG. 4, then with the pattern of FIG. 5 in a second shade, and finally with the pattern of FIG. 6 in a third shade. Centers 23 of each pattern are aligned and patterns 4 and 5 are rotationally aligned along radial lines RL3 and RL4. As seen in FIGS. 4 and 5, the jagged border between the portions of the iris sections having the first and second ...

example 4

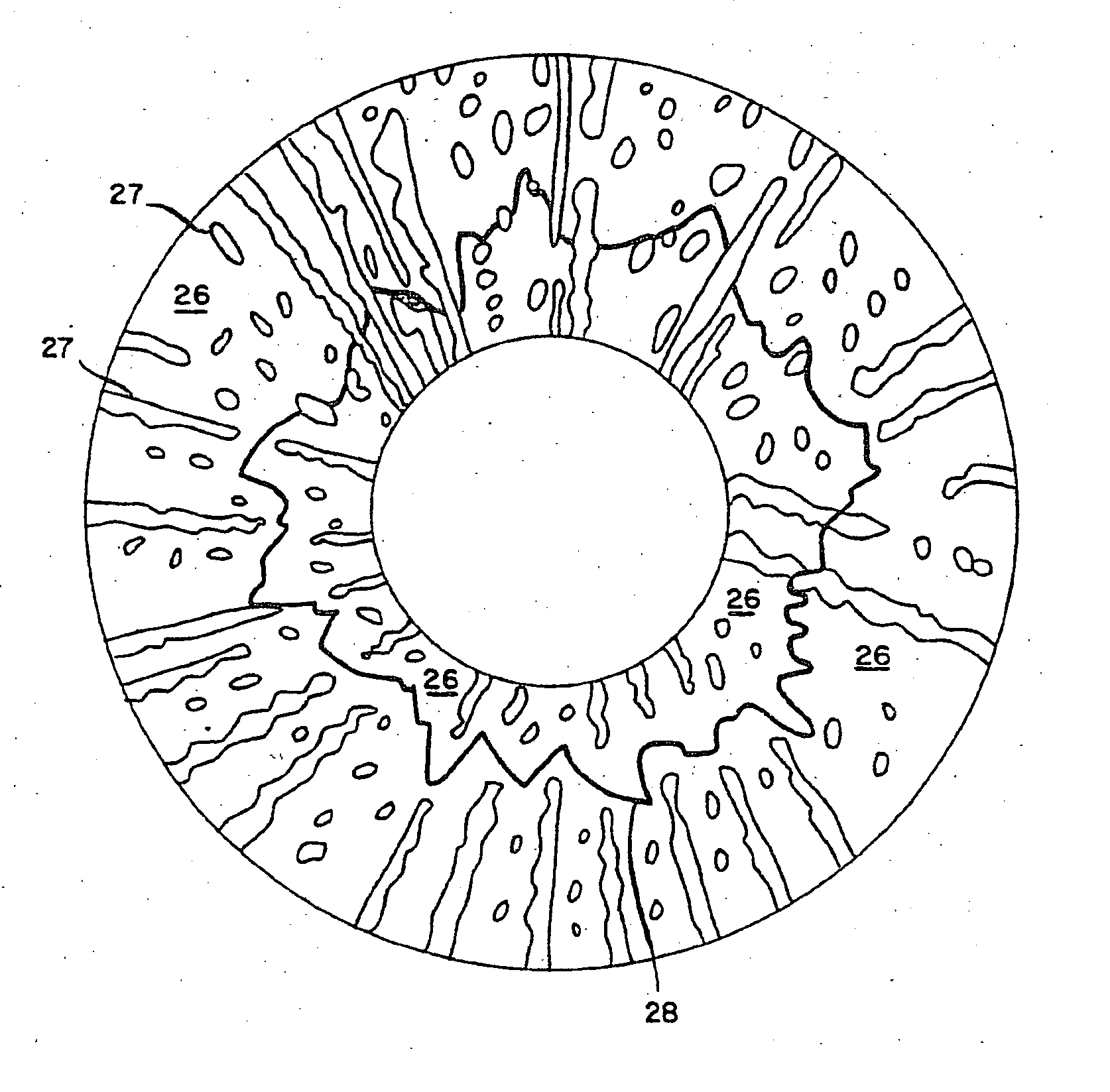

[0048] Prepare a lens in accordance with the second aspect of this invention by using the patterns of FIG. 7. In FIG. 7, an opaque iris section 26 has non-opaque elements 27 (only a few of which are labeled). The non-opaque elements of FIG. 7 are roughly radially elongated areas and dots. The opaque area has a first section of a first shade and a second inner section of a second shade different from the first shade, separated by jagged border 28.

EXAMPLE 5

[0049] Prepare a lens in accordance with the third aspect of the invention by using the patterns of FIG. 8. The iris section of the lens is opaque. An outer section 29 has a first shade and an inner section 30 has a second shade. Jagged border 31 separates sections 29 and 30.

[0050] Although lenses in accordance with Examples 4 and have not been produced, it is believed that they would achieve a far more natural appearance than the same lenses having a single color. Yet preparing lenses in accordance with these two embodiments is m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| inner radius R2 | aaaaa | aaaaa |

| inner radius R2 | aaaaa | aaaaa |

| outer radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com