Methods of well stimulation and completion

a well stimulation and well technology, applied in the field of improved methods for well stimulation and completion, can solve the problems of inability to achieve the desired flowback of proppant or formation fines with formation fluid, complex and potentially unstable fracture geometries, and damage to valves, instruments, and other production equipmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

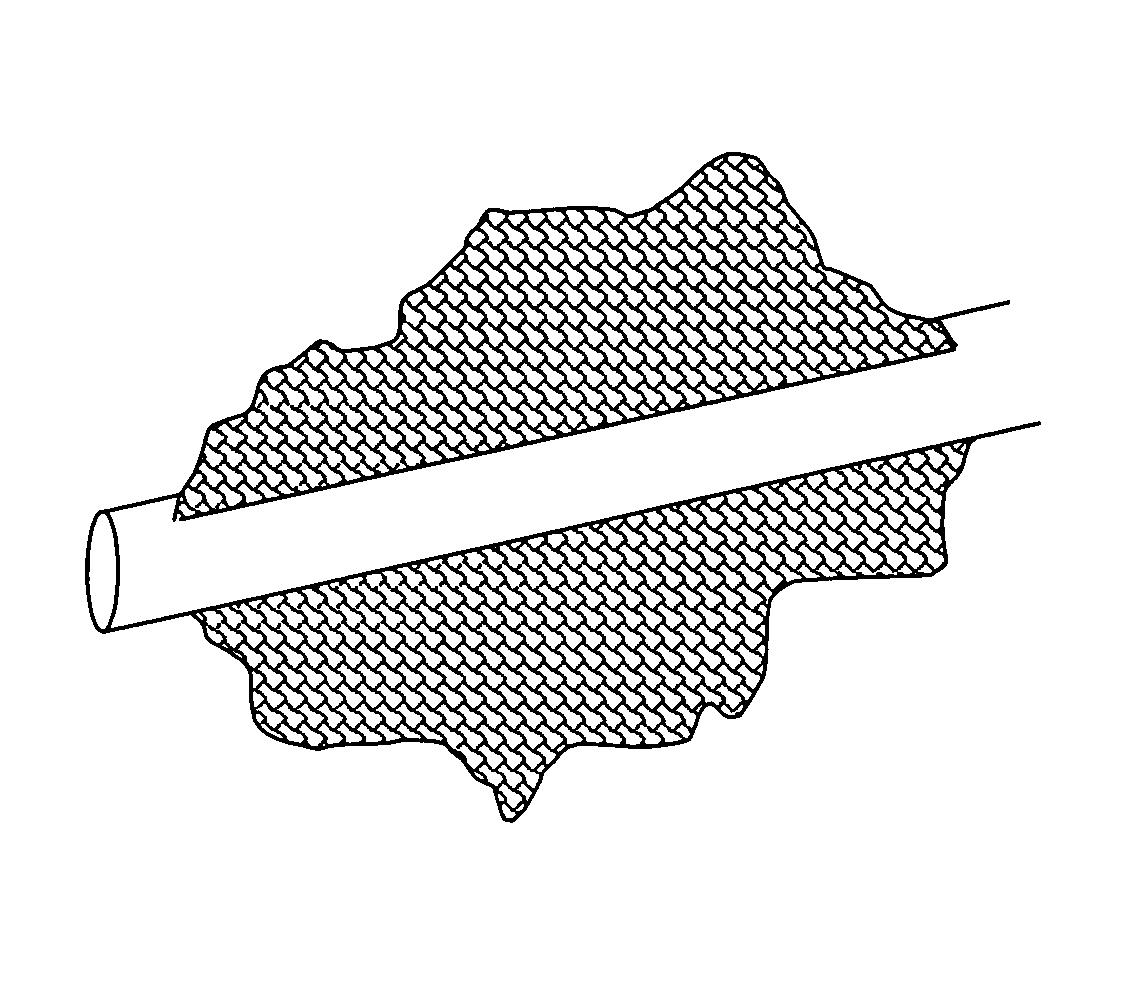

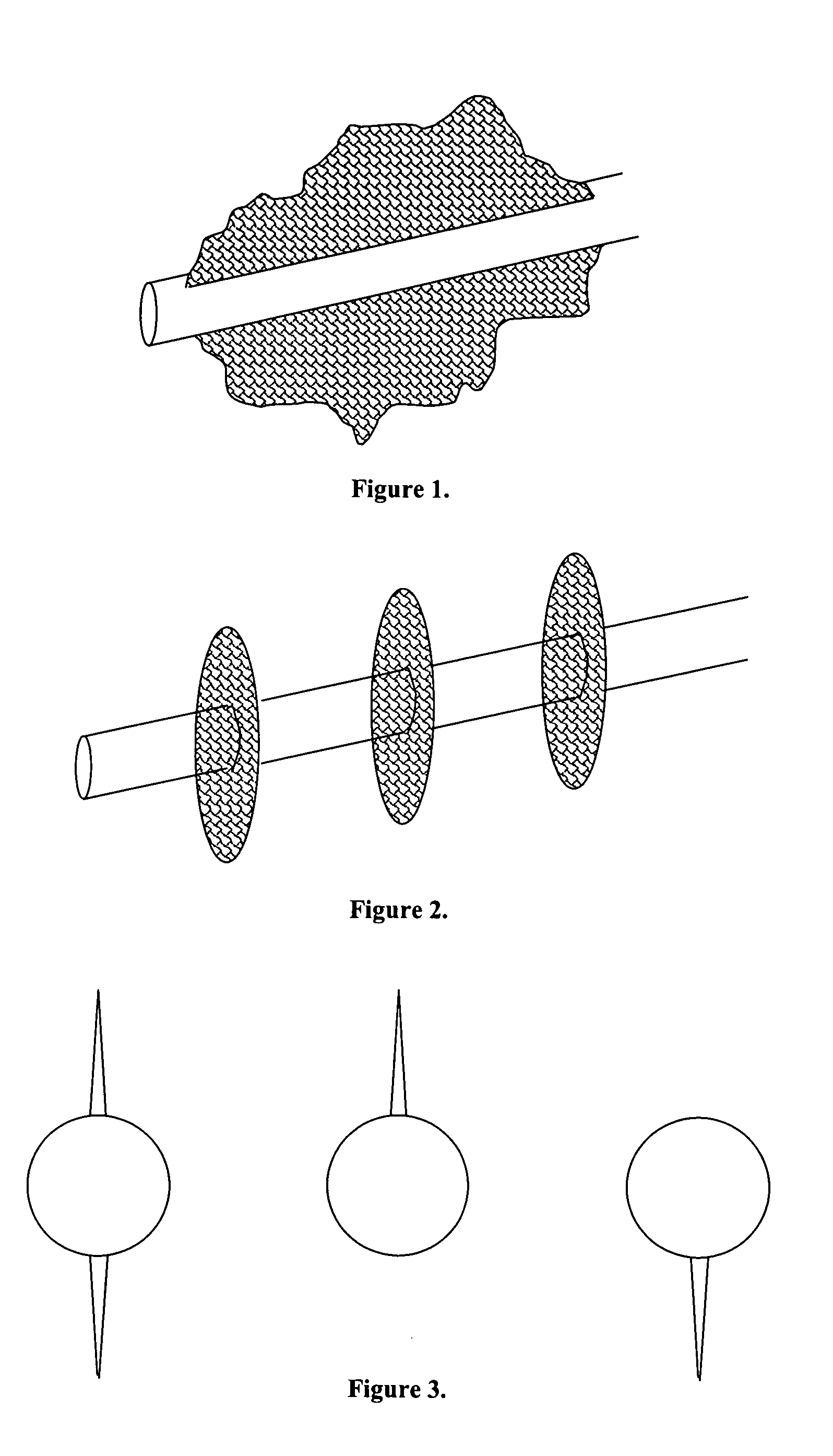

[0014] The present invention relates to improved methods for well stimulation and completion. More particularly, the present invention relates to methods of stimulating and completing well bores while controlling formation sand migration and proppant flowback.

[0015] Some embodiments of the present invention provide methods of stimulating hydrocarbon production and controlling particulate migration comprising the steps of (1) hydraulically fracturing a formation, (2) placing proppant coated with a tackifying agent into the far-well bore area of the fracture and then (3) placing an agent capable of controlling particulate flowback into the near-well bore area. The agent capable of controlling particulate flowback may be either proppant coated with curable resin or screen sized to control the flowback of the proppant coated with a tackifying agent in the well bore. Placing proppant coated with tackifying agent into the far-well bore area acts, inter alia, to help control the migration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com