Cushioning conversion system and method

a conversion system and cushioning technology, applied in the field of cushioning conversion system, can solve the problems of low skill level of packers (or operators), existing systems are labor intensive and time-consuming, and the need for low cost may preclude the use of low cost, so as to reduce the amount of necessary void filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

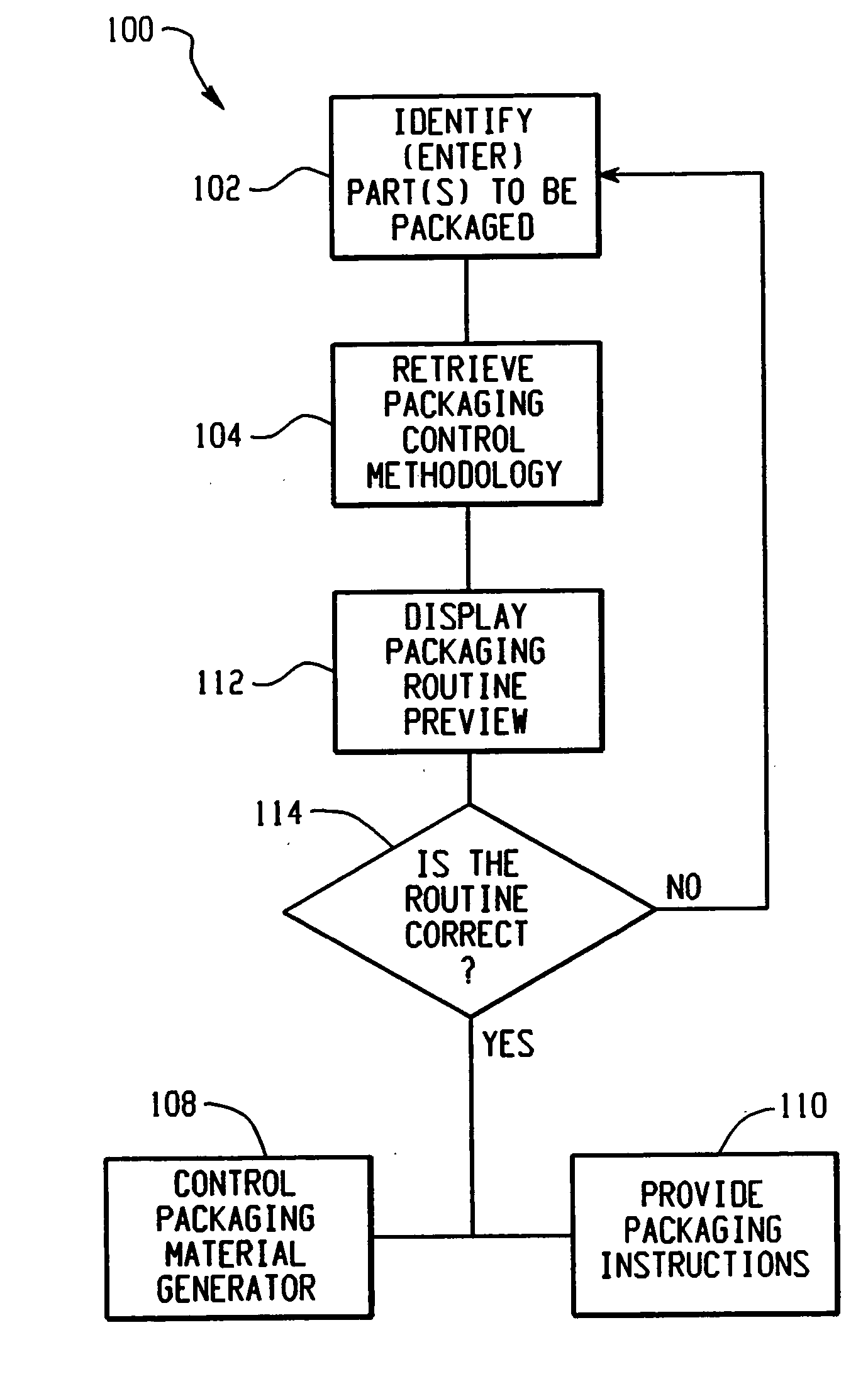

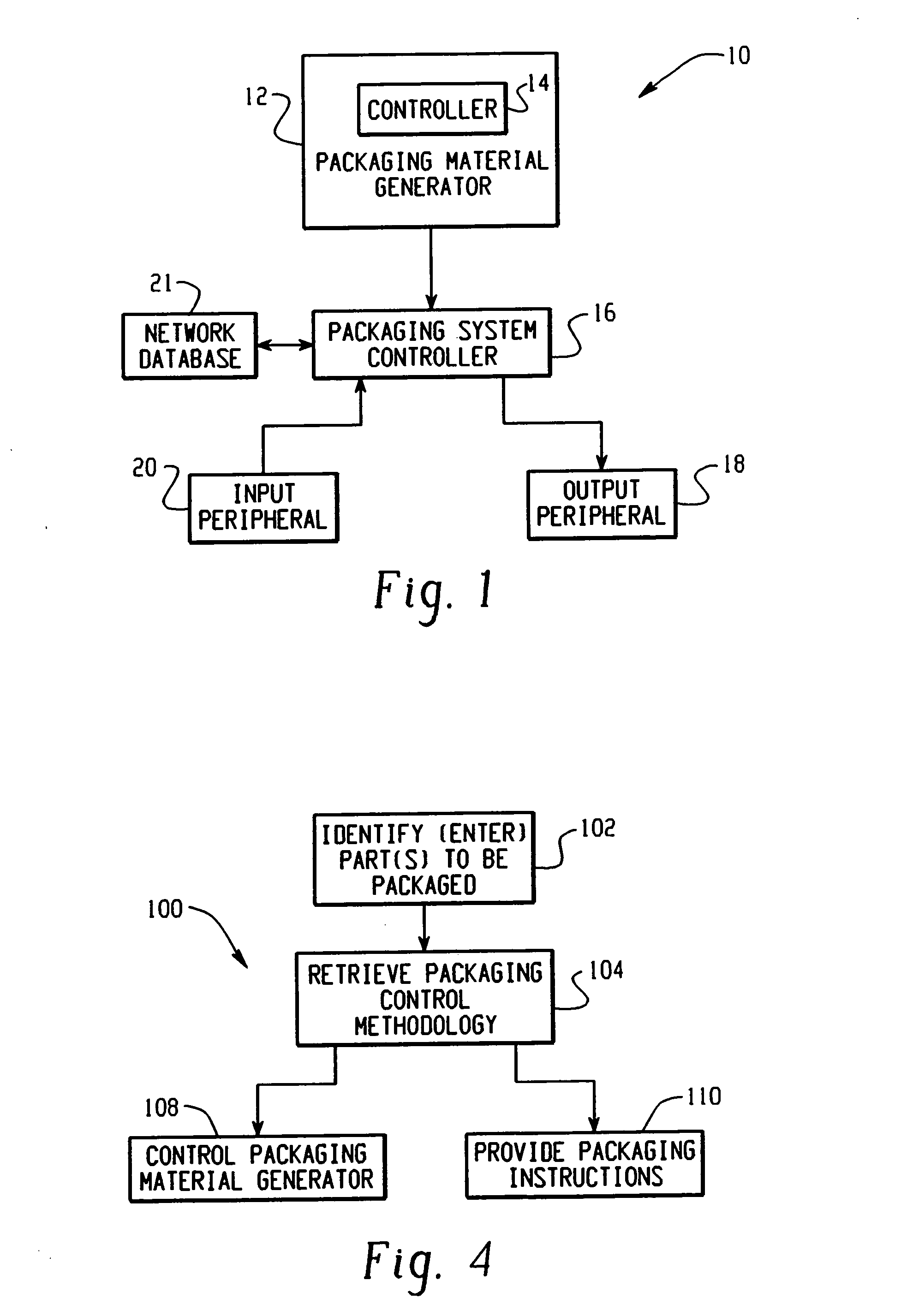

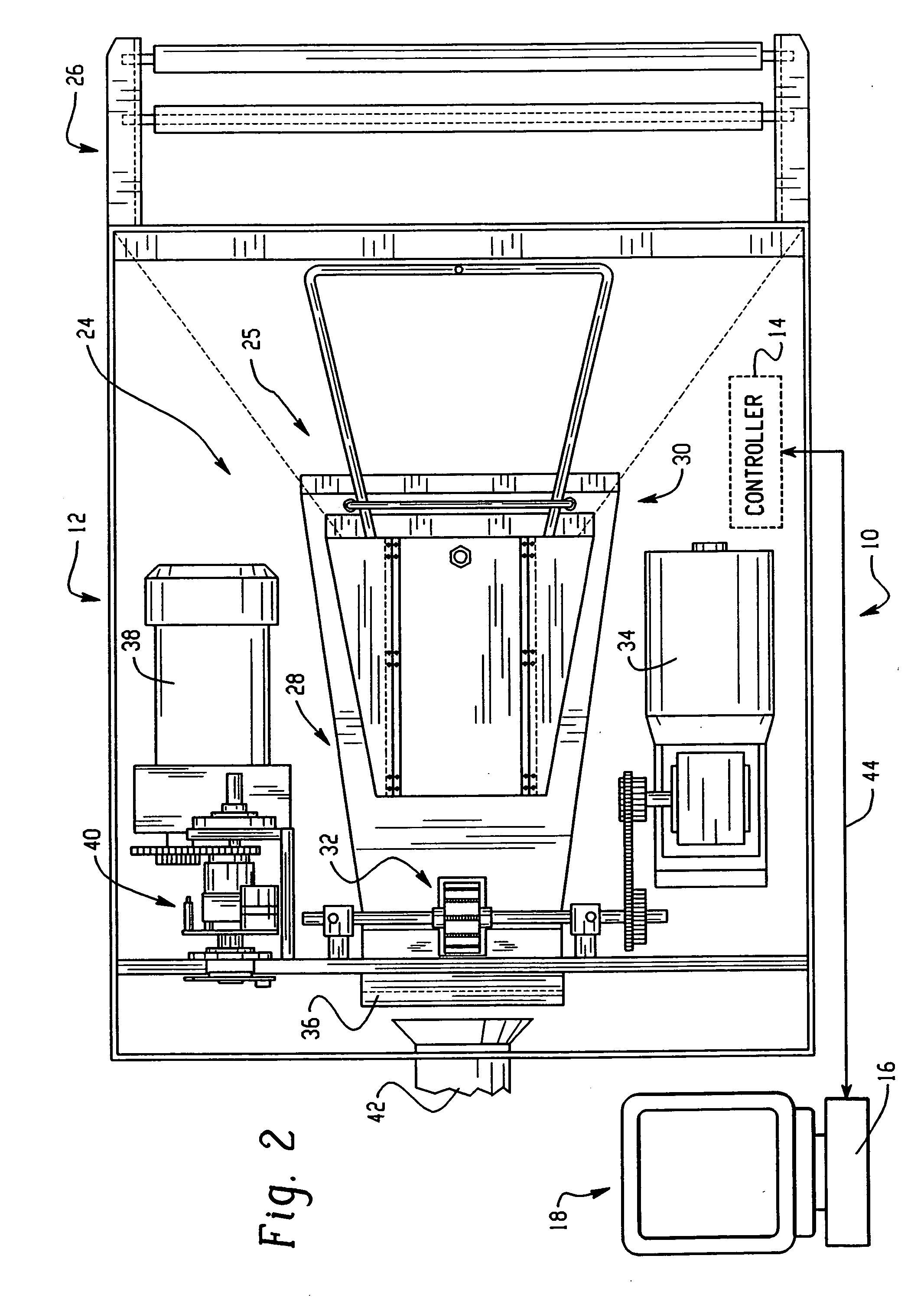

[0072] The present invention will now be described with reference to the drawings wherein reference numerals are used to refer to like elements throughout. In one embodiment of the present invention, an automated packaging system and method is disclosed which includes a packaging material generator such as a cushioning conversion machine and a packaging system controller. An operator, wishing to efficiently package a known, identified part, interacts with the packaging system to produce an appropriate amount of packaging material in an appropriate sequence for packaging the part within an identified container. In addition, the packaging system and method provides detailed packaging instructions to the operator in either a textual and / or pictorial format, thereby providing packaging efficiency and consistency which results in reduced part damage and reduced packaging costs.

[0073] According to a preferred embodiment of the present invention, a known part to be packaged is identified ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com