Filter cartridge and manifold for a water purification system

a filter cartridge and manifold technology, applied in the direction of filtration separation, multi-stage water/sewage treatment, separation process, etc., can solve the problems of undesired filter element removal, significant water leakage, and potential damage to adjoining flooring materials, so as to facilitate the removal and replacement of filter cartridges that are substantially fail-safe and substantially drip-free, and quick and easy respective connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

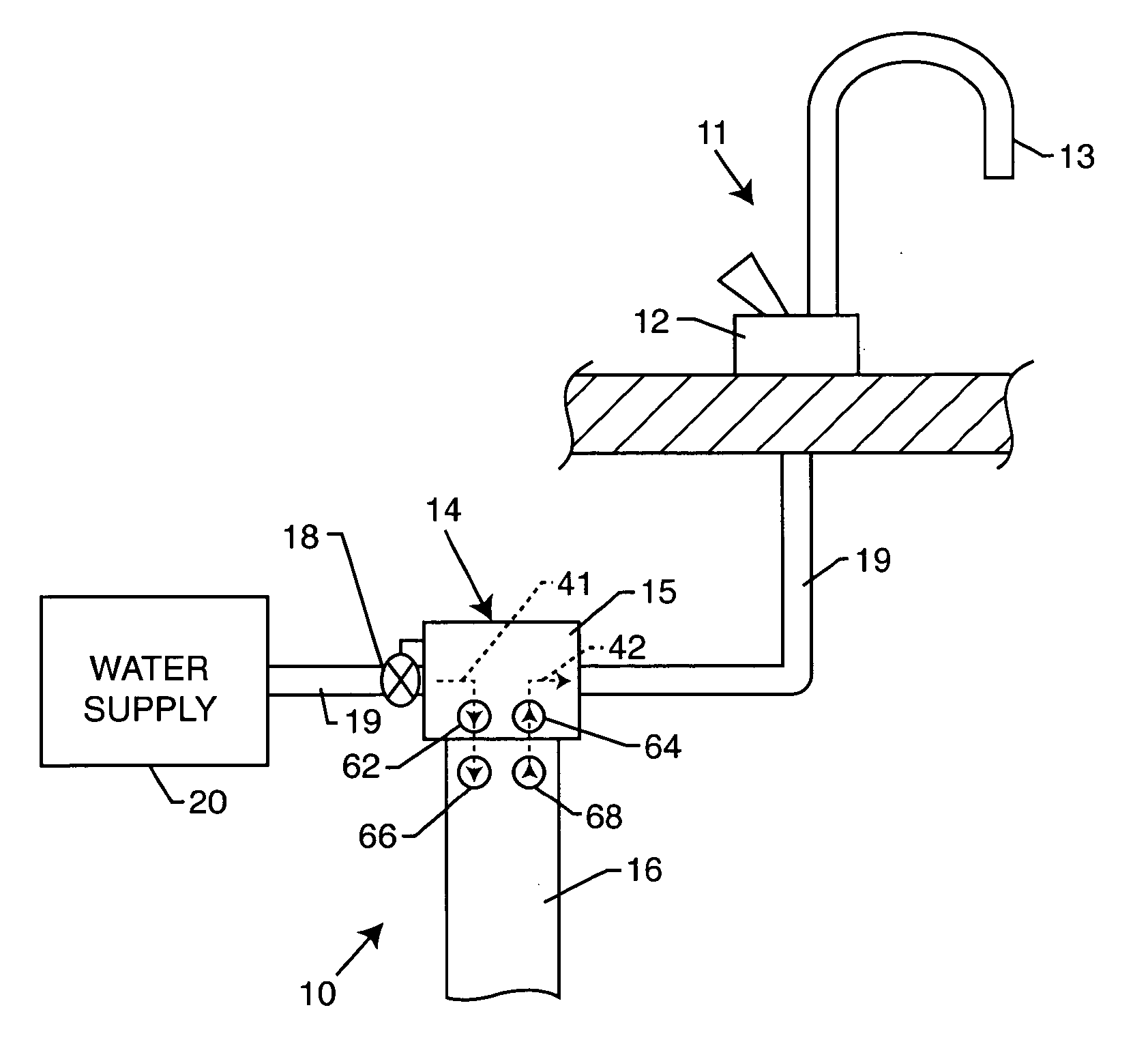

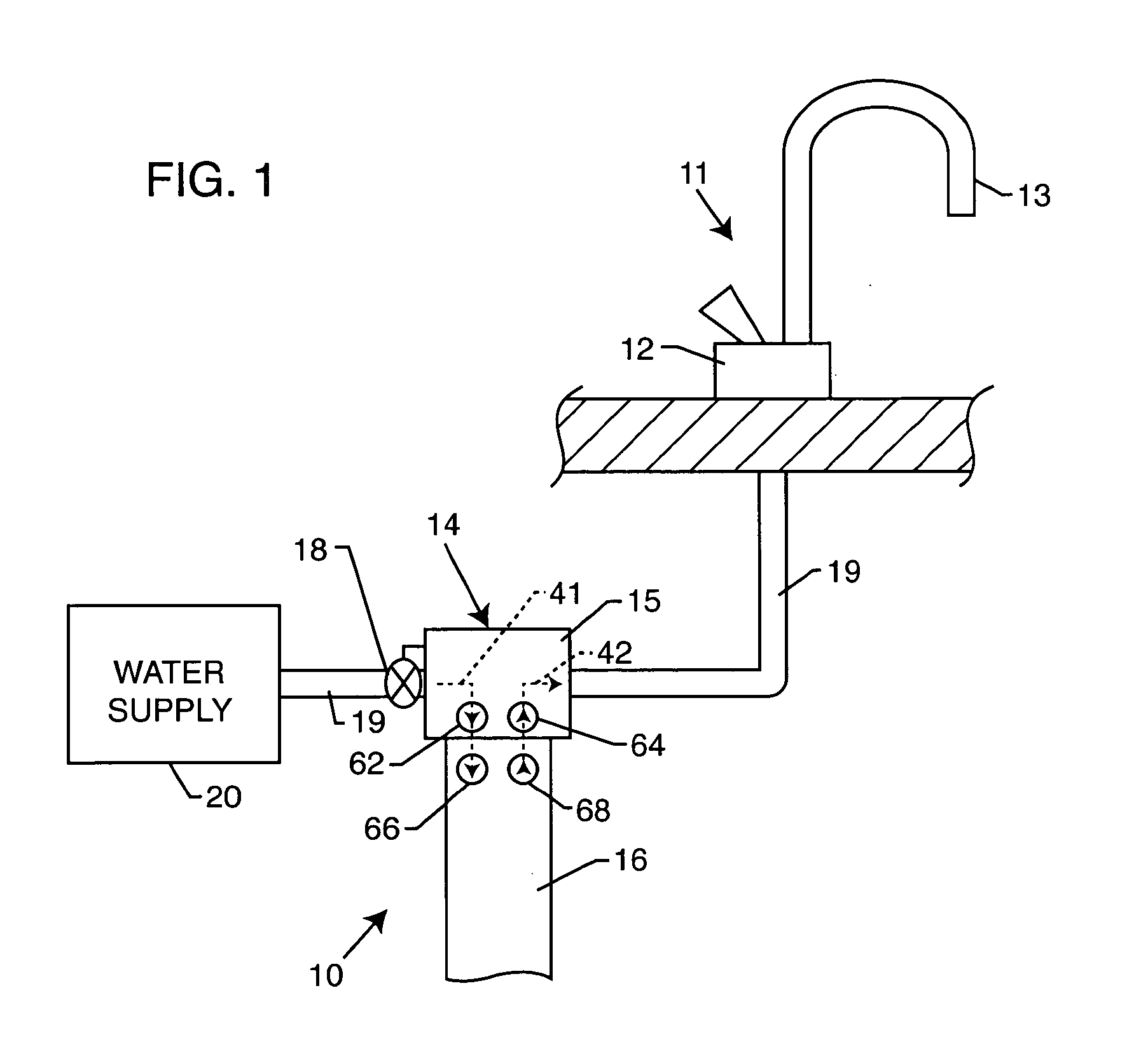

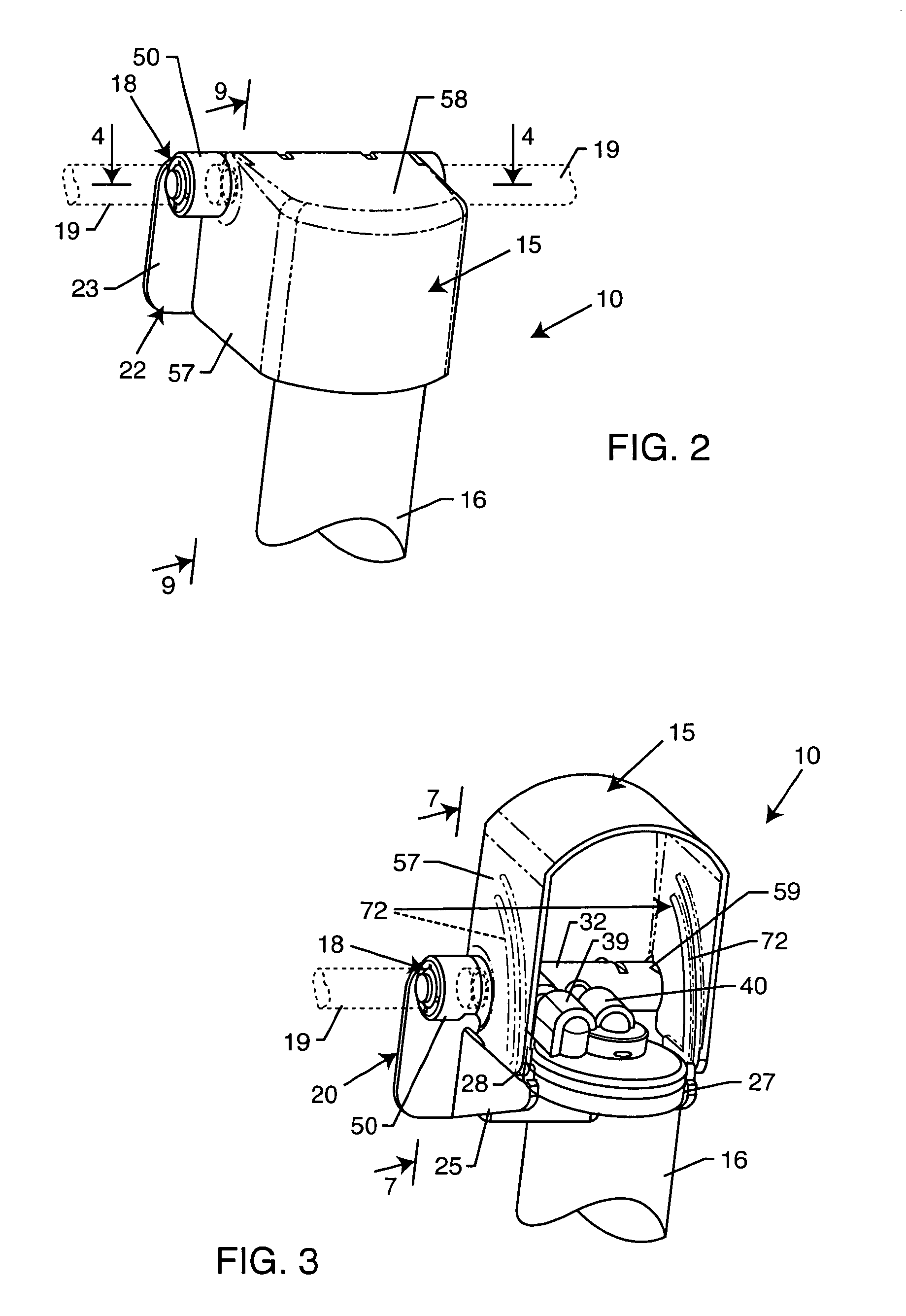

[0032] As shown in the exemplary drawings, a combined filter cartridge and manifold system referred to generally in FIG. 1 by the reference numeral 10 is provided for providing relatively purified water for dispensing by means of a faucet 11 or the like including (as shown) a suitable faucet valve 12 for regulating dispense water flow through a faucet spout 13 or the like. The cartridge and manifold system 10 includes a manifold 14 having a pivotally movable manifold cap 15 for normally retaining and supporting a removable filter cartridge 16 to produce purified water for dispensing, as viewed in FIGS. 2 and 9. The manifold cap 15 can be raised from a normally closed position (FIGS. 2 and 9) to an open position (FIGS. 3 and 7) initially closing a water supply valve 18 and then exposing and releasing the filter cartridge 16 for quick and easy removal and replacement. The manifold 14 and the filter cartridge 16 includes one-way check valves which close upon cartridge removal from the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| rotary angle | aaaaa | aaaaa |

| sliding displacement | aaaaa | aaaaa |

| displacement | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com