Dispenser for rolled strip material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

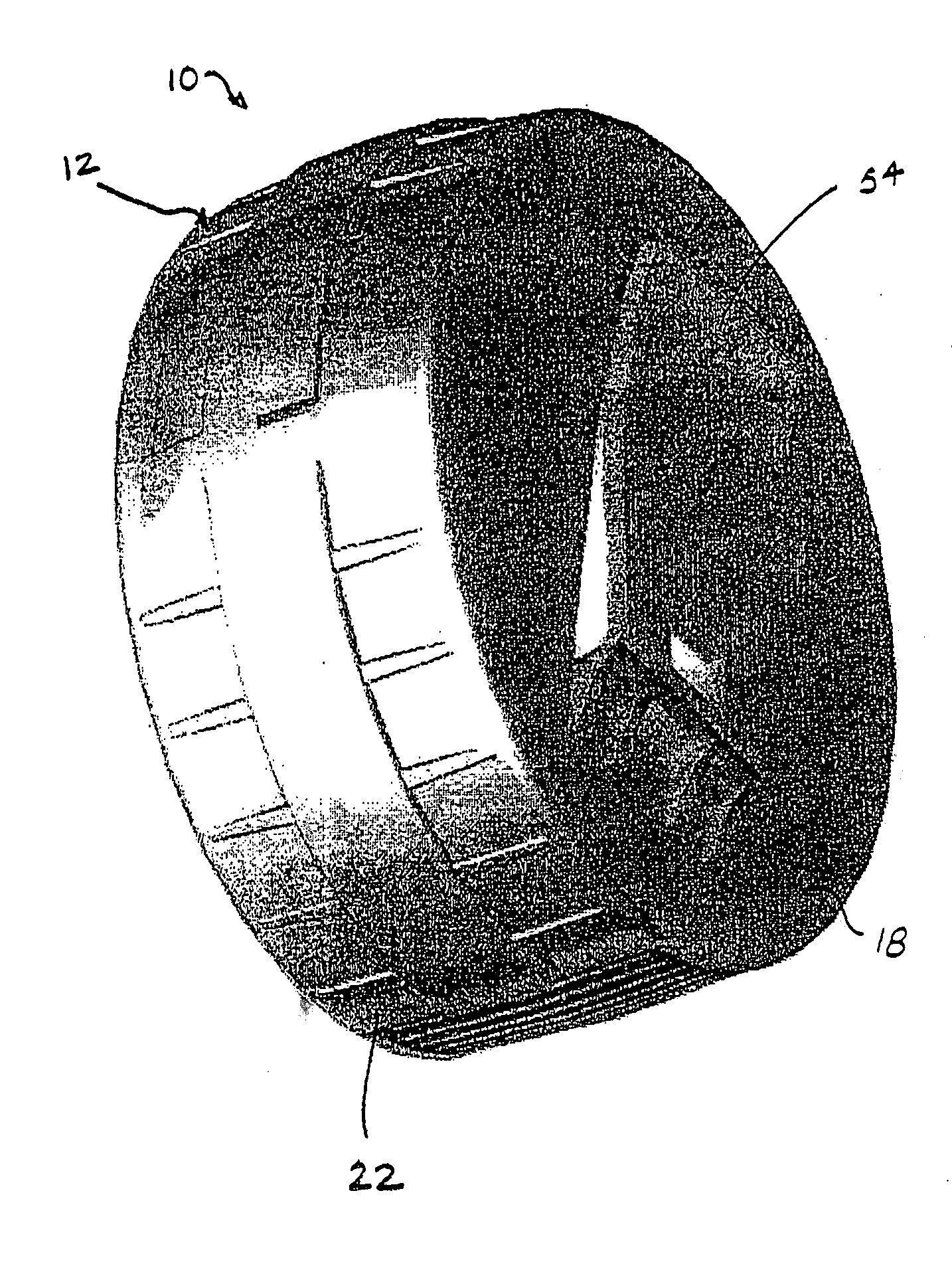

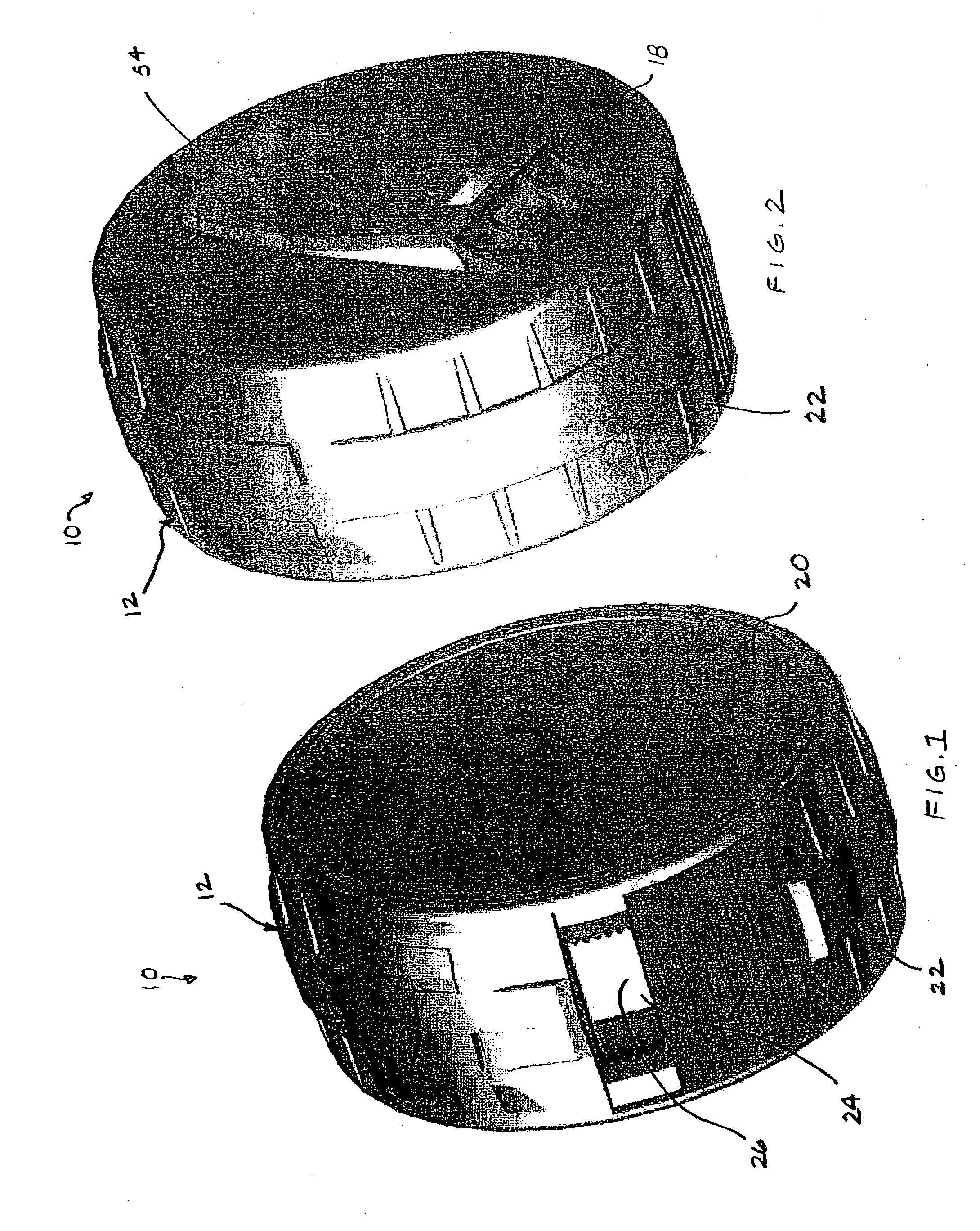

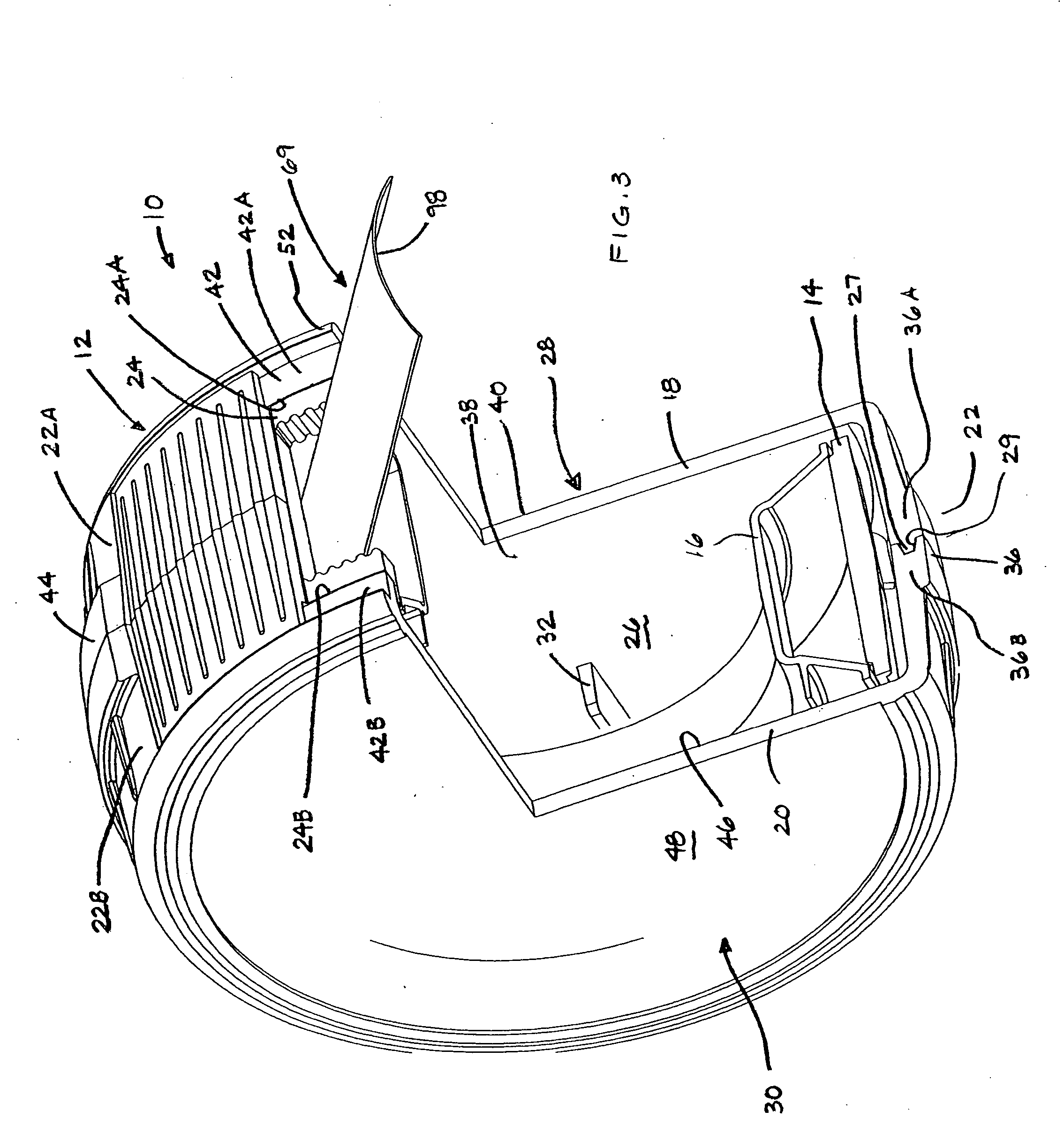

[0020] Referring to FIGS. 1-4, a rolled material dispenser 10 is provided that includes a housing 12, a ring 14, and a spool 16. The housing 12 has a first end panel 18, a second end panel 20, and at least one side panel 22 extending between the end panels 18, 20. A window 24 is disposed in the side panel. An internal cavity 26 is disposed between the end panels 18, 20 and the at least one side panel 22. The window 24 provides access to the internal cavity 26.

[0021] In the embodiment shown in FIGS. 3-7, the housing 12 is a two-piece assembly that includes a base 28 and a cover 30. The base 28, shown sectioned in FIG. 3 and separately in FIG. 6, includes the first end panel 18, a first side panel portion 22A, a plurality of guides 32, a first half 34A of a connector couple 34 for connecting the base 28 to the cover 30, and a first half 36A of a seal couple 36 for forming a seal between the base 28 and the cover 30. The first end panel 18 is circular in shape and includes an inner su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com