Cushion and trim cover for contoured cushion presenting seat

a cushion and seat technology, applied in the field of seat cushion trim covers, can solve the problems of cushion binding, poor aesthetics of the cover material, and difficulty in cushioning, and achieve the effect of reducing strain and fatigue, and being easy to mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

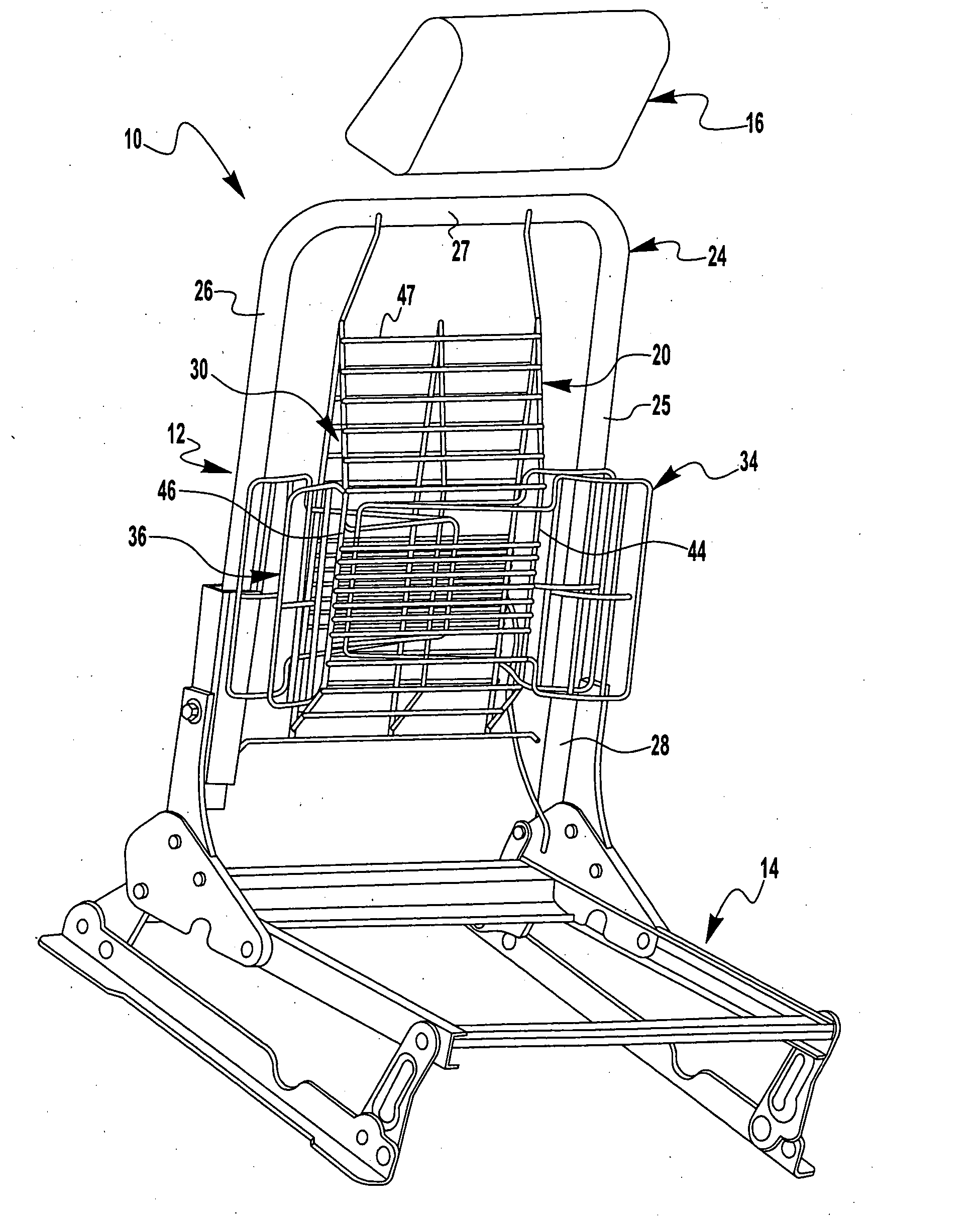

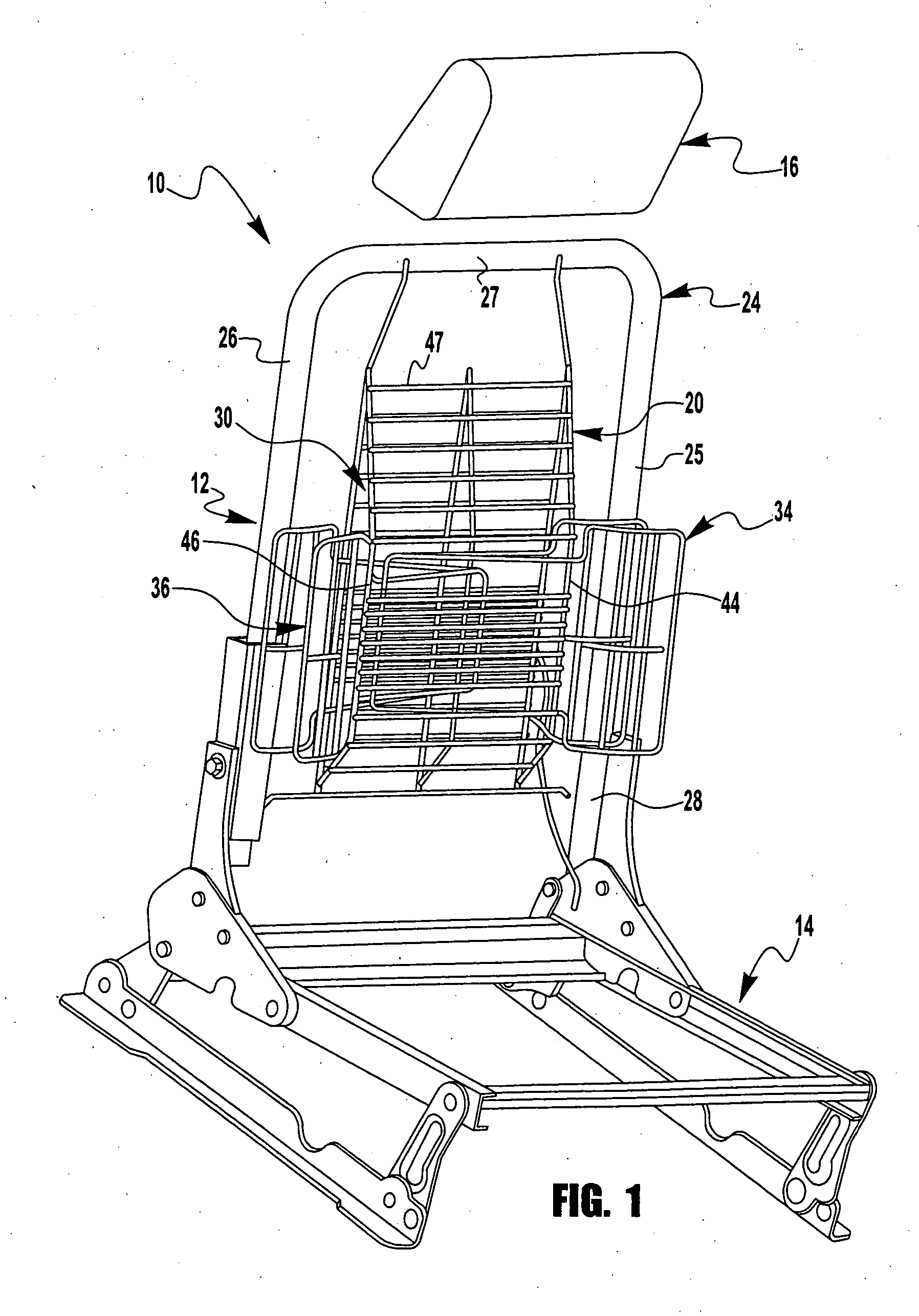

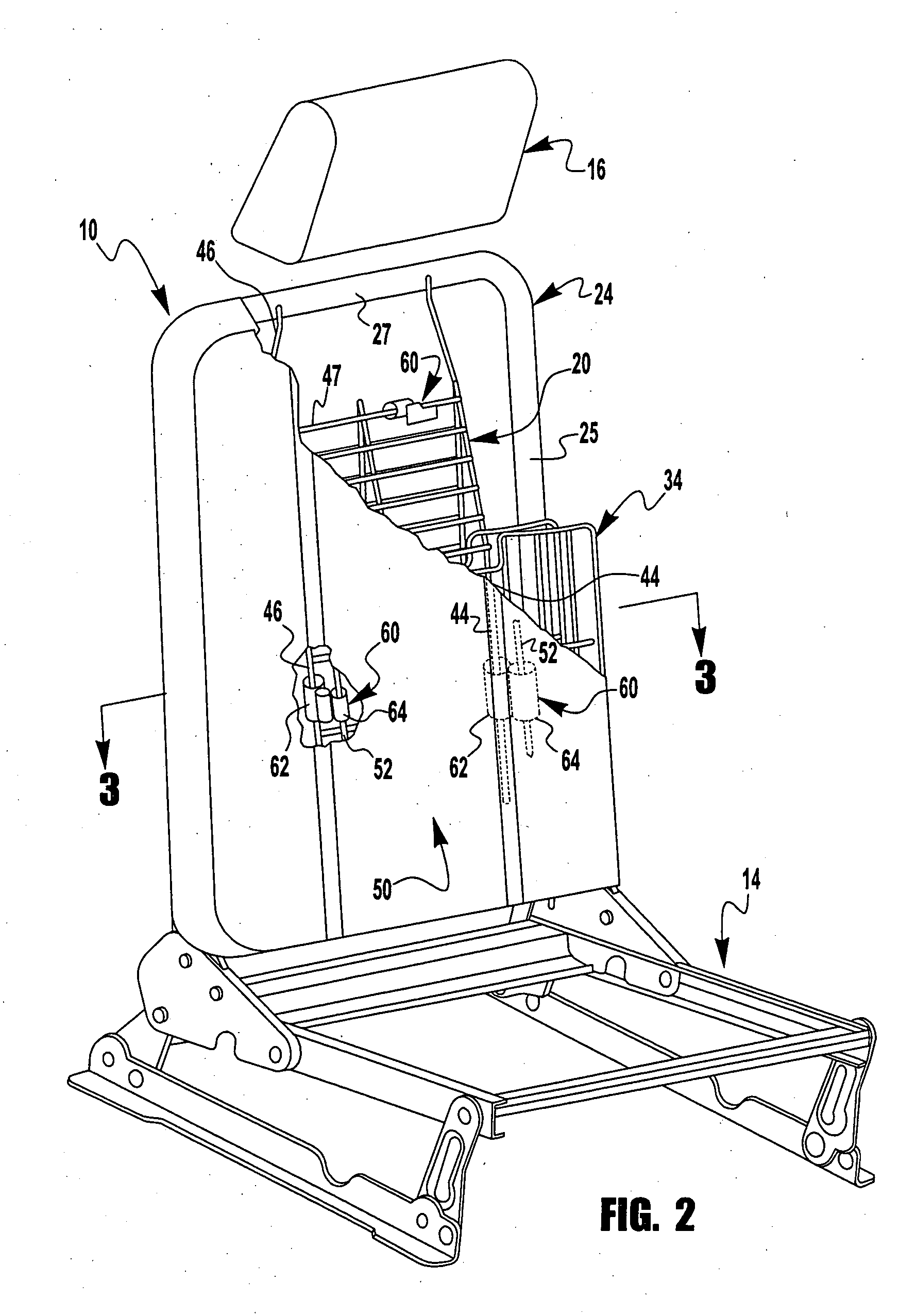

[0029] Referring generally to the figures and particularly to FIG. 1, there is shown a folding vehicle seat 10 including a seat back 12 and a seat base 14. Seat 10 further alternatively includes a headrest 16 which may be attached using any known or suitable attachment member at an upper end of seat back 12 as is conventional in the art of vehicle seats.

[0030] Preferably seat back 12 is provided with a seat cushion presenting device, shown as a contour presenting device 20, such as that disclosed in U.S. Provisional Patent Application No. 60 / 454,263, filed on Mar. 13, 2003, entitled “SEAT CUSHION PRESENTER DEVICE FOR FOLDING SEAT,” the full disclosure of which is hereby incorporated herein by reference in its entirety as well as that disclosed in PCT Patent Application No. PCT / US03 / 35565, filed Nov. 7, 2003.

[0031] It should be noted that contour presenting device 20 may be any known or suitable contour presenting device that is suitable for presenting a cushion. For example, conto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com