Rotary bolt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

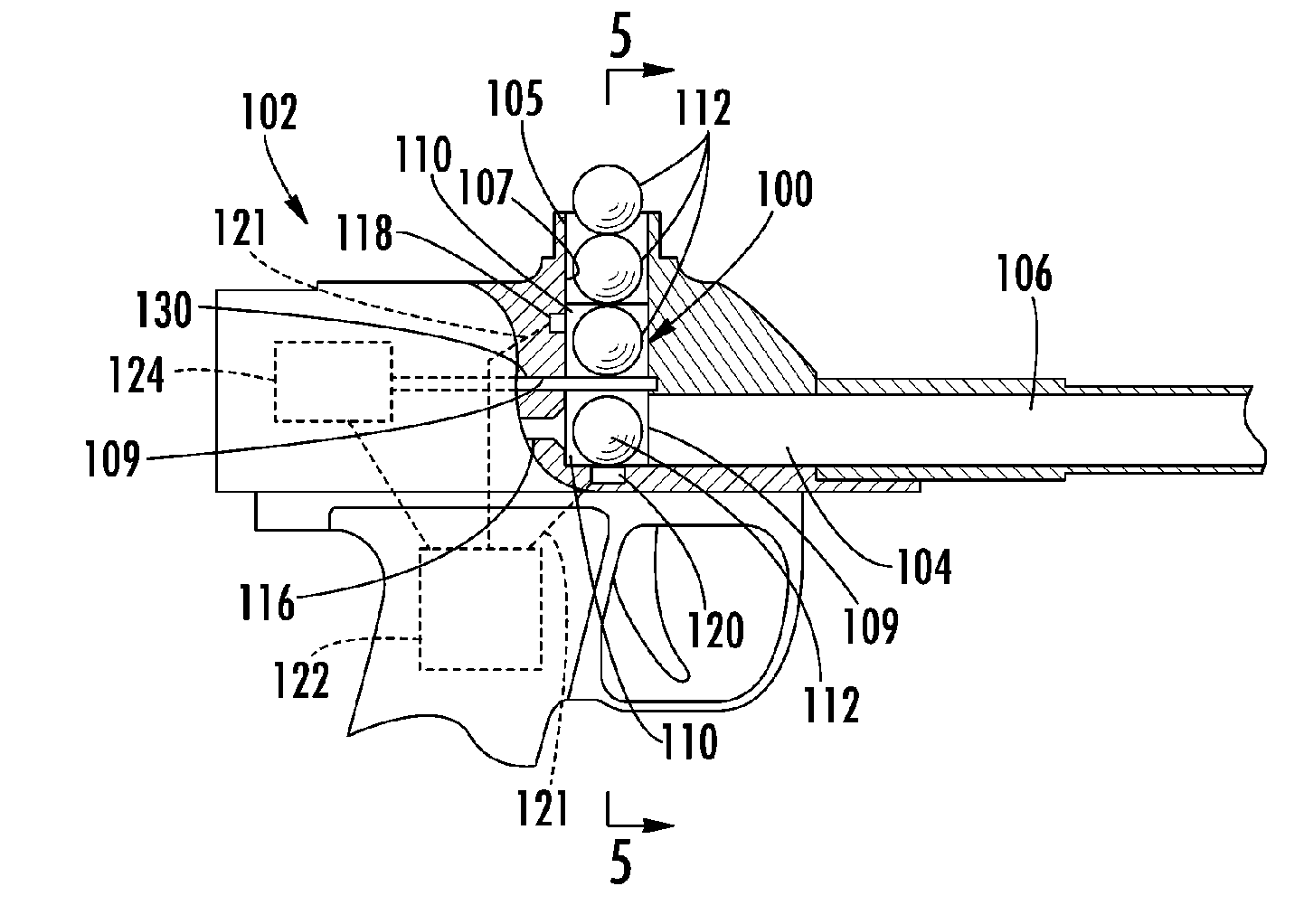

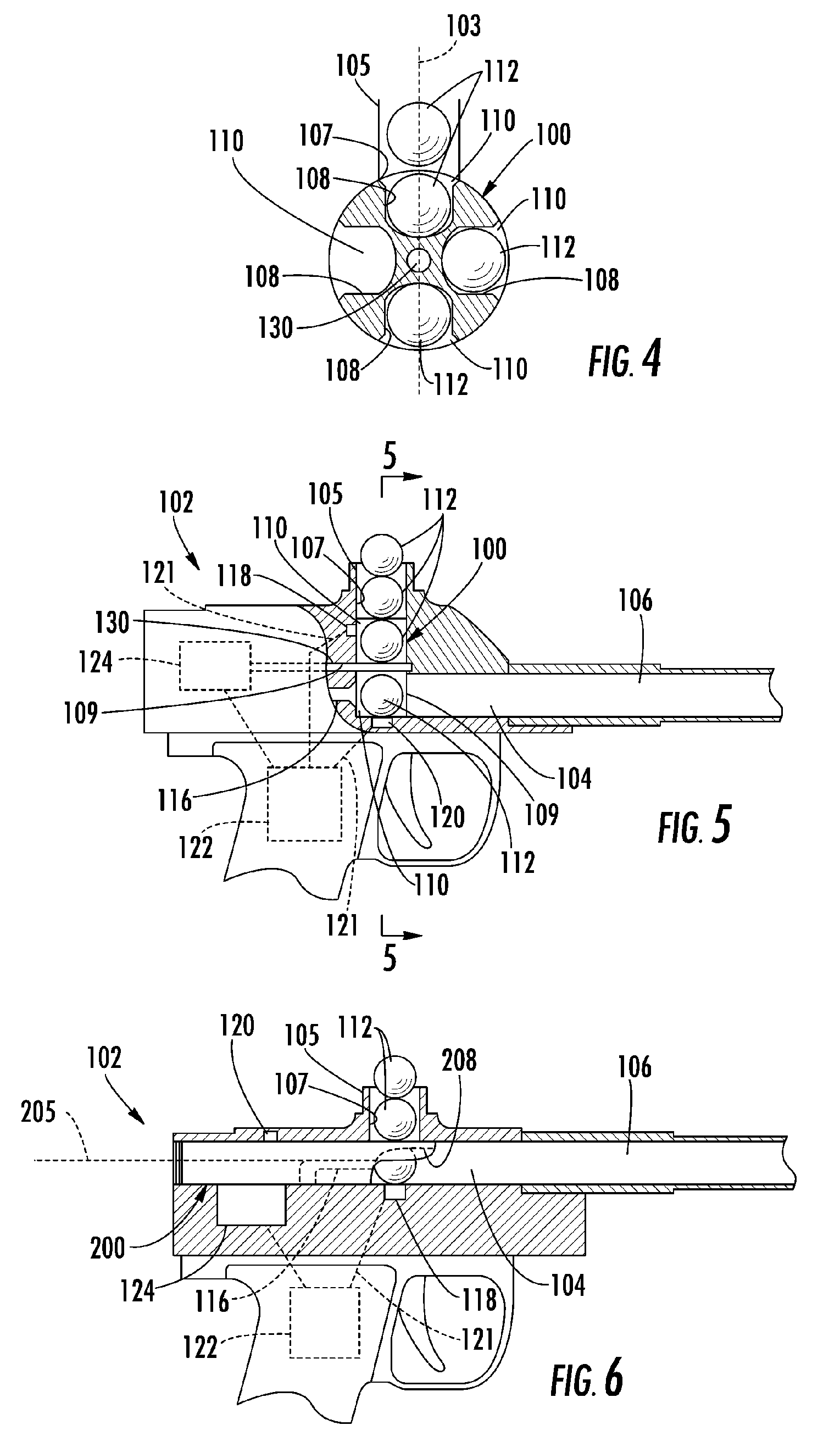

[0023] Referring now to FIGS. 4 and 5, the preferred embodiment of the present invention is shown generally at 100 mounted within a representational projectile launcher 102. The bolt system of the present invention can be used in any projectile launching device. Such devices include paintball markers. For ease of illustration and discussion, the present invention is shown in a paintball marker; however, the invention is intended to cover use in any type of projectile launching device.

[0024] The projectile launcher 102, such as a paintball marker, has a central breech 104. Extending from the breech 104 is the barrel 106. A feed conduit 105 leads to the breech 104 of the paintball marker 102 forming a feed aperture 107. A hopper (not shown) can also be used to gravity feed paintball projectiles 112 into the feed aperture 107. Projectiles 112 flow down the feed conduit 105 and out the feed aperture 107. The rotary bolt 100 of the present invention receives the projectile 112 from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com