Semiconductor light emitting device and method for manufacturing same

a technology of light-emitting devices and semiconductors, which is applied in the direction of semiconductor devices, thermoelectric device junction materials, electrical equipment, etc., can solve the problems of color tone variation, more visible color tone variation, and different thicknesses, and achieve uniform color tone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

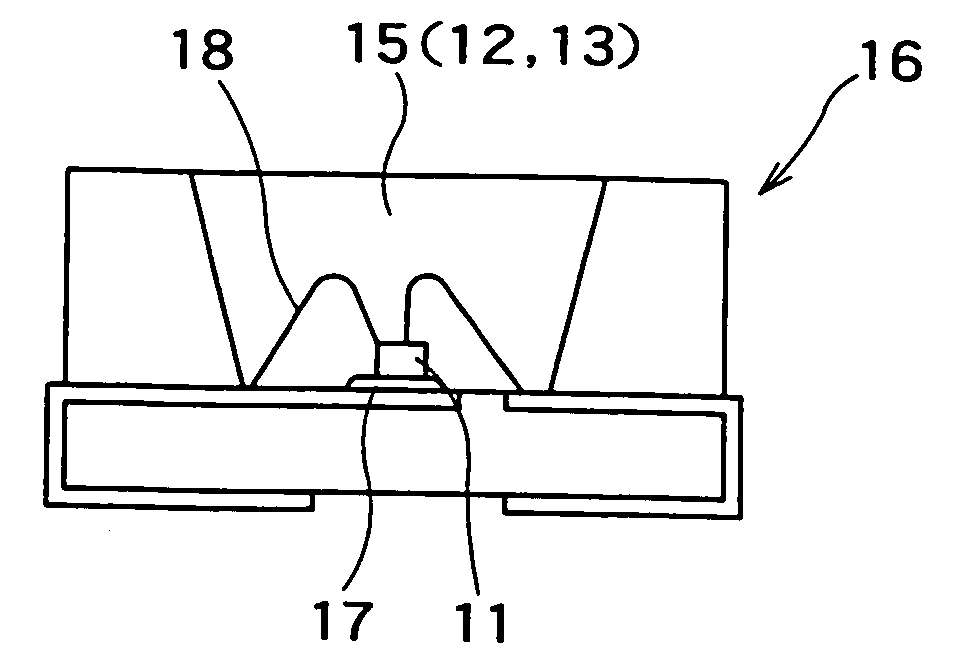

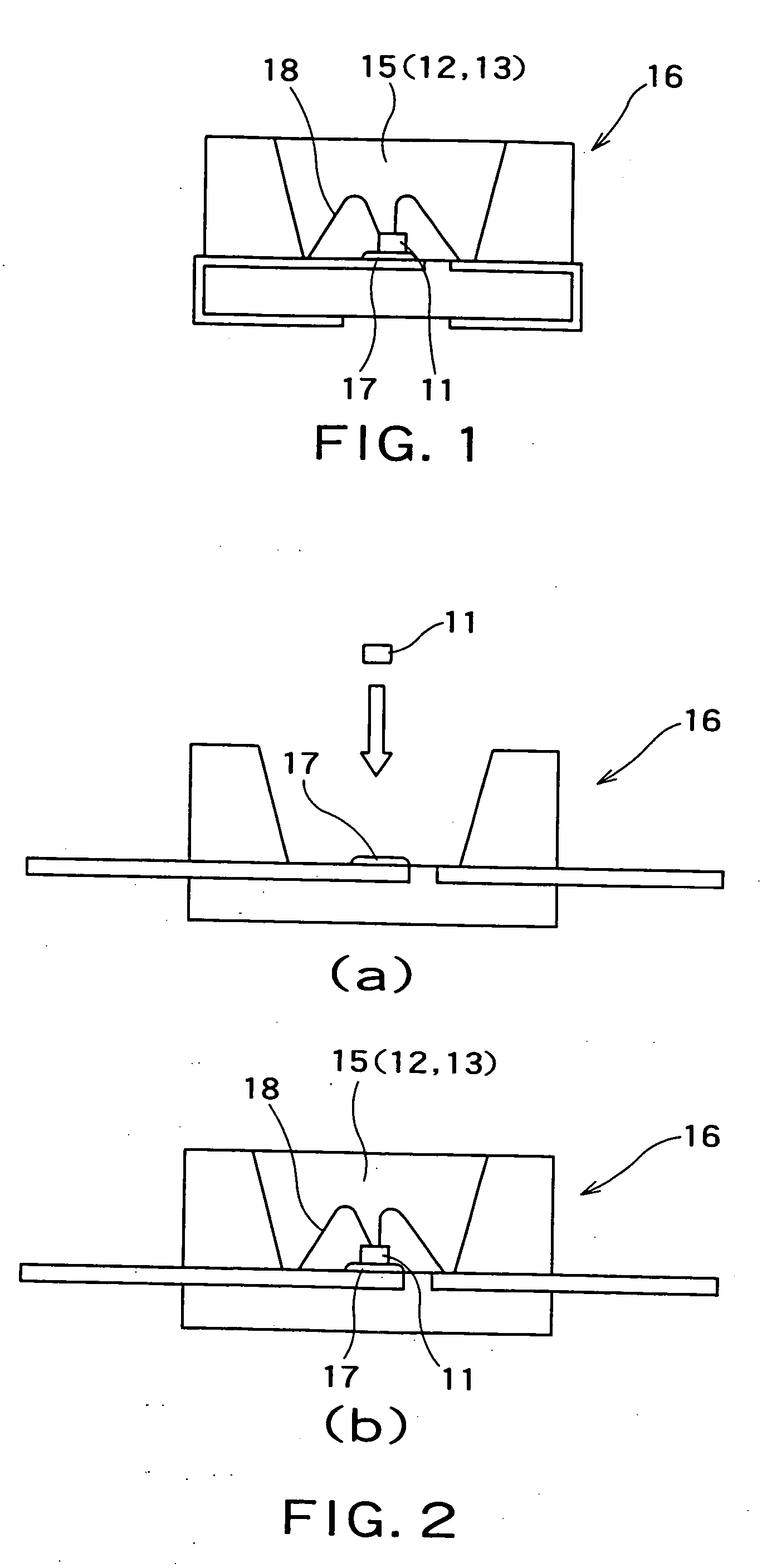

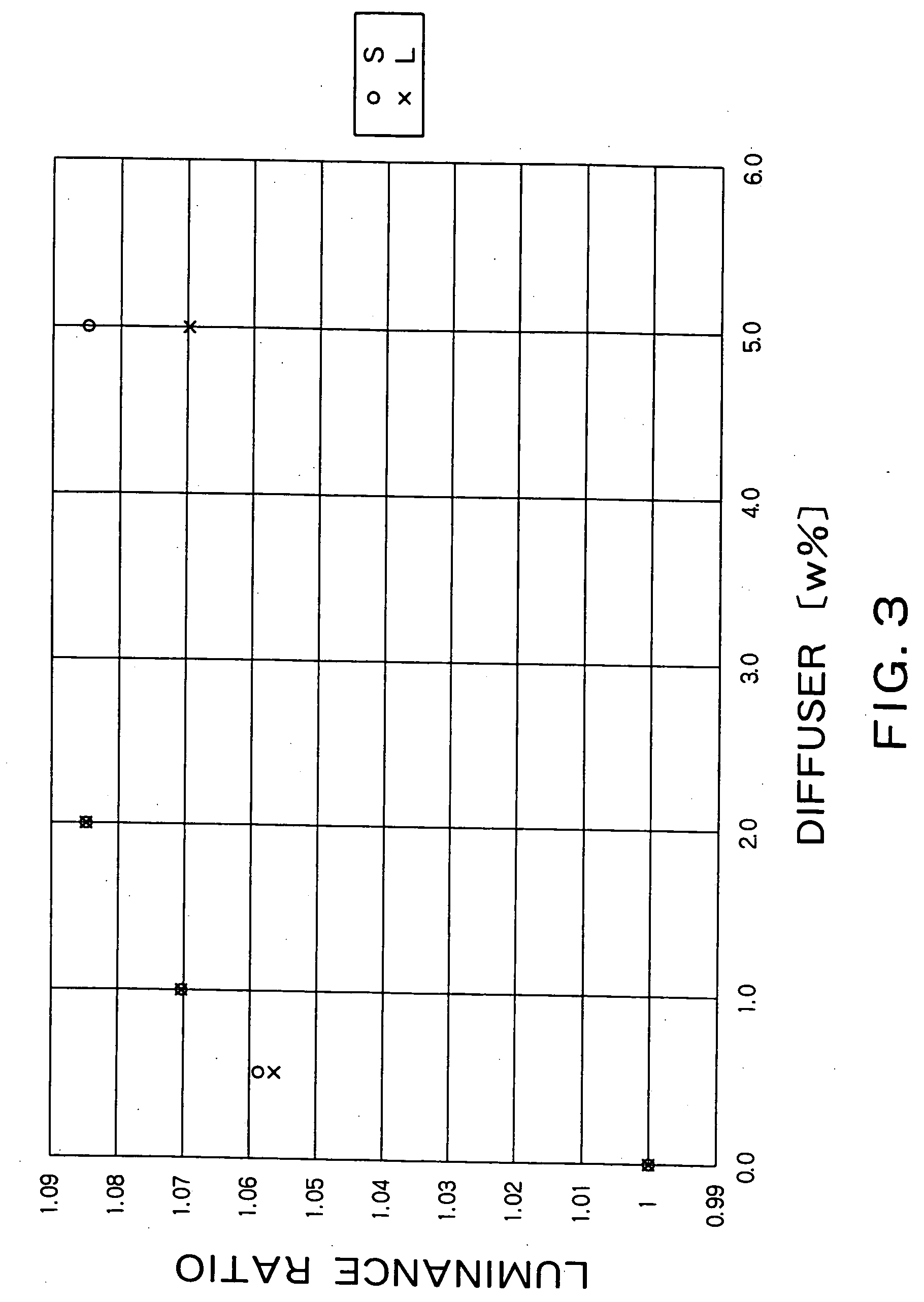

[0055] The semiconductor light emitting device taken as the first embodiment is a semiconductor light emitting device for emitting white light, which is called a surface mounted device (hereinafter abbreviated as SMD). One of features of the semiconductor light emitting device according to the instant embodiment lies in, as shown in FIG. 1, introducing an appropriate amount of diffuser 13 into silicone resin used as sealing resin 15. Used as a semiconductor light emitting element 11 is an element made of GaN materials and emitting ultraviolet light when a current is injected. Used as fluorescent materials 12 are three kinds of fluorescent materials, namely, a red fluorescent material excited by ultraviolet emission to emit red light, a green fluorescent material excited by ultraviolet emission to emit green light, and a blue fluorescent material excited by ultraviolet emission to emit blue light (hereinafter abbreviated as RGB fluorescent materials). Used as the diffuser 13 is alumi...

second embodiment

[0078] A semiconductor light emitting device according to the second embodiment comprises, as shown in FIG. 5, a sealing resin 25, a binder 24 in which fluorescent materials 22 and a diffuser 23 are mixed, which are formed as separate elements. Configuration of the product, kind of the semiconductor light emitting element 21, kinds of the fluorescent materials 22 and kind of the diffuser 23 are the same as those of the first embodiment.

[0079]FIG. 5 is a schematic cross-sectional view of the semiconductor light emitting device according to the second embodiment. The semiconductor light emitting element 21 made of GaN materials and emitting ultraviolet light upon injection of a current is bonded inside a reflector of a frame 26 with an adhesive 27 such as silver paste. Both p and n electrodes of the semiconductor light emitting device 21 are connected to the frame 26 by a wire 28 of Au, for example. A lower portion inside the reflector of the frame 26 in the view of FIG. 5 is filled ...

third embodiment

[0097] A semiconductor light emitting device according to the third embodiment comprises, as shown in FIG. 8, a binder 34 in which fluorescent materials 32, an adherent or cohesive medium 33a in which a diffuser 33 is mixed, and sealing resin 35, which are formed as separate elements. Configuration of the product, kind of the semiconductor light emitting element 31, kinds of the fluorescent materials 32 and kind of the diffuser 33 are the same as those of the second embodiment.

[0098]FIG. 8 is a schematic cross-sectional view of the semiconductor light emitting device according to the third embodiment. The semiconductor light emitting element 31 made of GaN materials and emitting ultraviolet light upon injection of a current is bonded inside a reflector of a frame 36 with an adhesive 37 such as silver paste. Both p and n electrodes of the semiconductor light emitting device 31 are connected to the frame 36 by a wire 38 of Au, for example. A lower portion inside the reflector of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com