Preparation method of high-strength waterproof color ardealite brick

A production method and high-strength technology, applied in the field of building materials, can solve the problems of low strength, poor durability, insufficient strength, etc., and achieve the effects of good water resistance and acid corrosion resistance, solving quality defects, and solving high costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The mixed raw materials of phosphogypsum bricks were obtained by selecting and mixing materials according to conventional methods, and the raw materials were prepared according to the batch test volume of 1000 pieces, 2460 kg of phosphogypsum brick mixed materials, and 24 kg of chromium-based inorganic pigments. Phosphogypsum brick mixture includes conventional phosphogypsum, cementitious material, lime, aggregate.

[0026] Put the mixed raw materials of phosphogypsum bricks that have been aged to meet the requirements into the roller mixer and stir for 2 minutes, then add chromium-based inorganic pigments and stir for 5 minutes; add water and stir for 4 minutes to obtain a mixed slurry with a uniform color; then use a hydraulic vibration molding machine Make the brick body; use saturated steam to cure at 90°C to make the finished color phosphogypsum brick, randomly sample for testing, the results are:

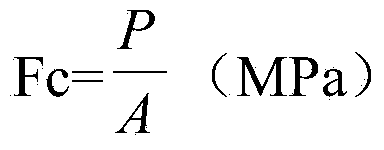

[0027] Compressive strength: 21.3MPa;

[0028] Uniform tone;

[...

Embodiment 2

[0033] According to conventional methods, materials are selected and mixed to obtain the mixed raw materials of phosphogypsum bricks, and the raw materials are prepared according to the batch test volume of 1000 pieces, 2460 kg of phosphogypsum brick mixed materials, and 49 kg of ultramarine blue pigment.

[0034]Put the mixed raw materials of phosphogypsum bricks that have been aged to meet the requirements into the wheel roller mixer and stir for 2 minutes, then add ultramarine blue pigment and stir for 3 minutes; add water and stir for 5 minutes to obtain a mixed slurry with uniform color tone; then use the hydraulic vibration molding machine Make the brick body; use saturated steam to cure at 110°C to make the finished color phosphogypsum brick, randomly sample for testing, the results are:

[0035] Compressive strength: 23.7MPa;

[0036] Uniform tone;

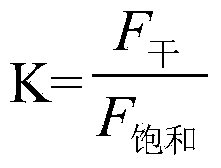

[0037] Softening coefficient: 0.86;

[0038] Carbonization coefficient: 0.89;

[0039] Water Absorption: 13%.

Embodiment 3

[0041] The mixed raw materials of phosphogypsum bricks were obtained by selecting and taking materials according to conventional methods, and the raw materials were prepared according to the batch test volume of 1000 pieces, 2460 kg of phosphogypsum brick mixed materials, and 37 kg of iron red composite inorganic pigments.

[0042] Put the mixed raw materials of phosphogypsum bricks that have been aged to meet the requirements into the roller mixer and stir for 2 minutes, then add iron red composite inorganic pigment and stir for 2 minutes; add water and stir for 5 minutes to obtain a mixed slurry with uniform color tone; then use hydraulic vibration molding Machine-made brick body; use saturated steam to cure at 120°C to make finished colored phosphogypsum bricks, randomly sample for testing, the results are:

[0043] Compressive strength: 25.3MPa;

[0044] Uniform tone;

[0045] Softening coefficient: 0.90;

[0046] Carbonization coefficient: 0.88;

[0047] Water absorpti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com