Mounting clip and related modular storage system

a modular storage system and mounting clip technology, applied in the field of storage systems, can solve the problems of high cost, numerous components, no known system that allows easy relocation of mounting standards, etc., and achieve the effect of being cheap to manufactur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

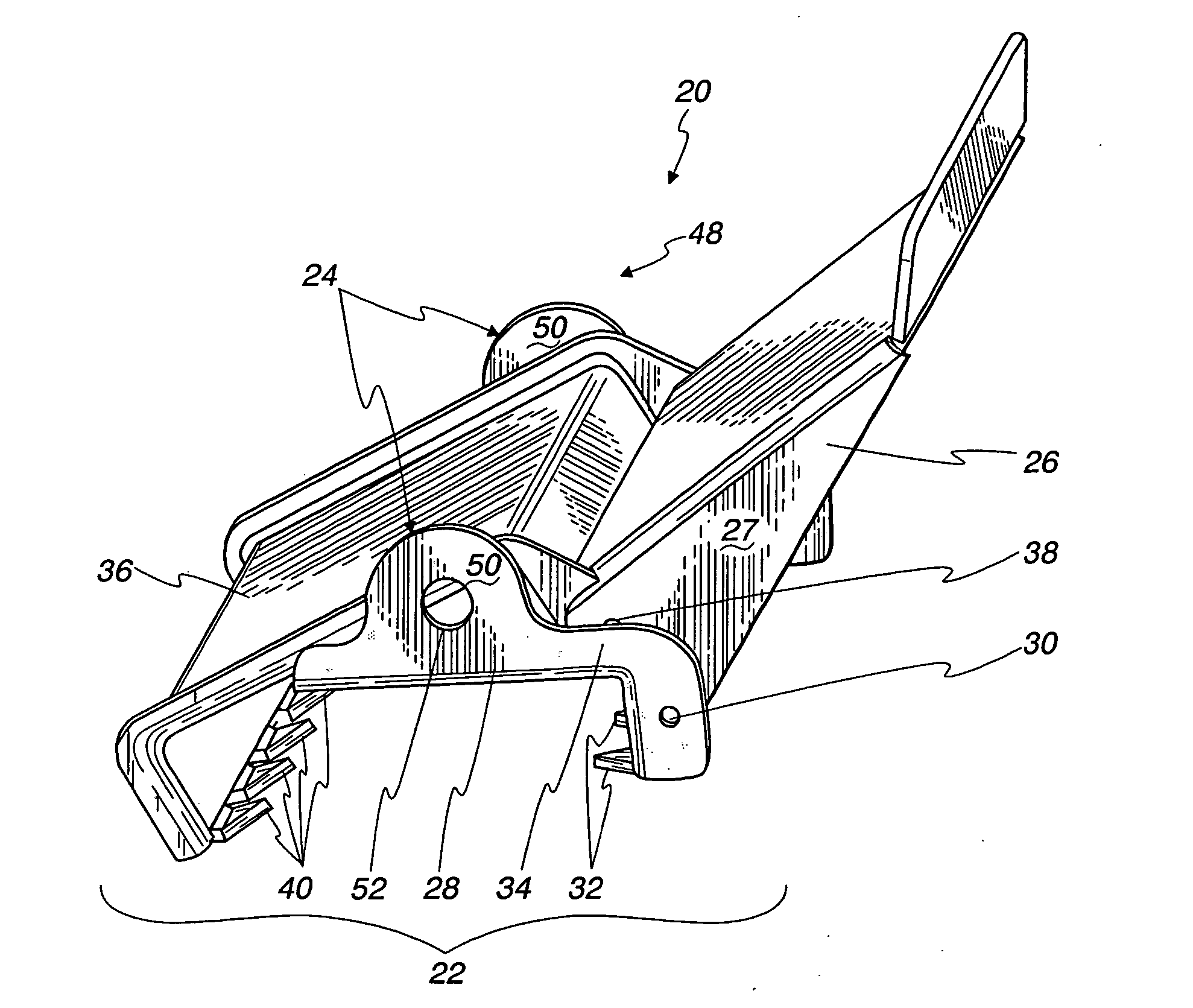

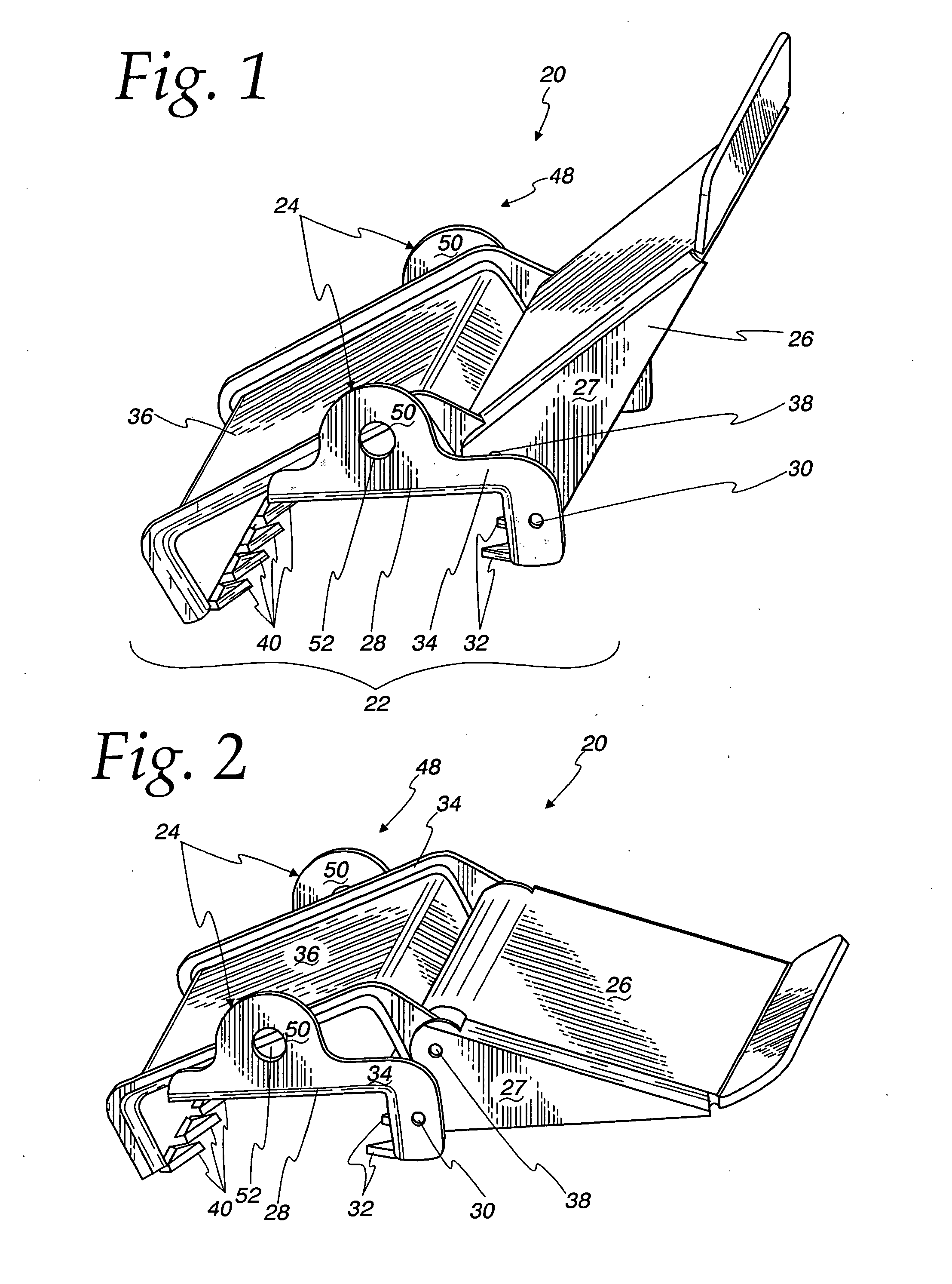

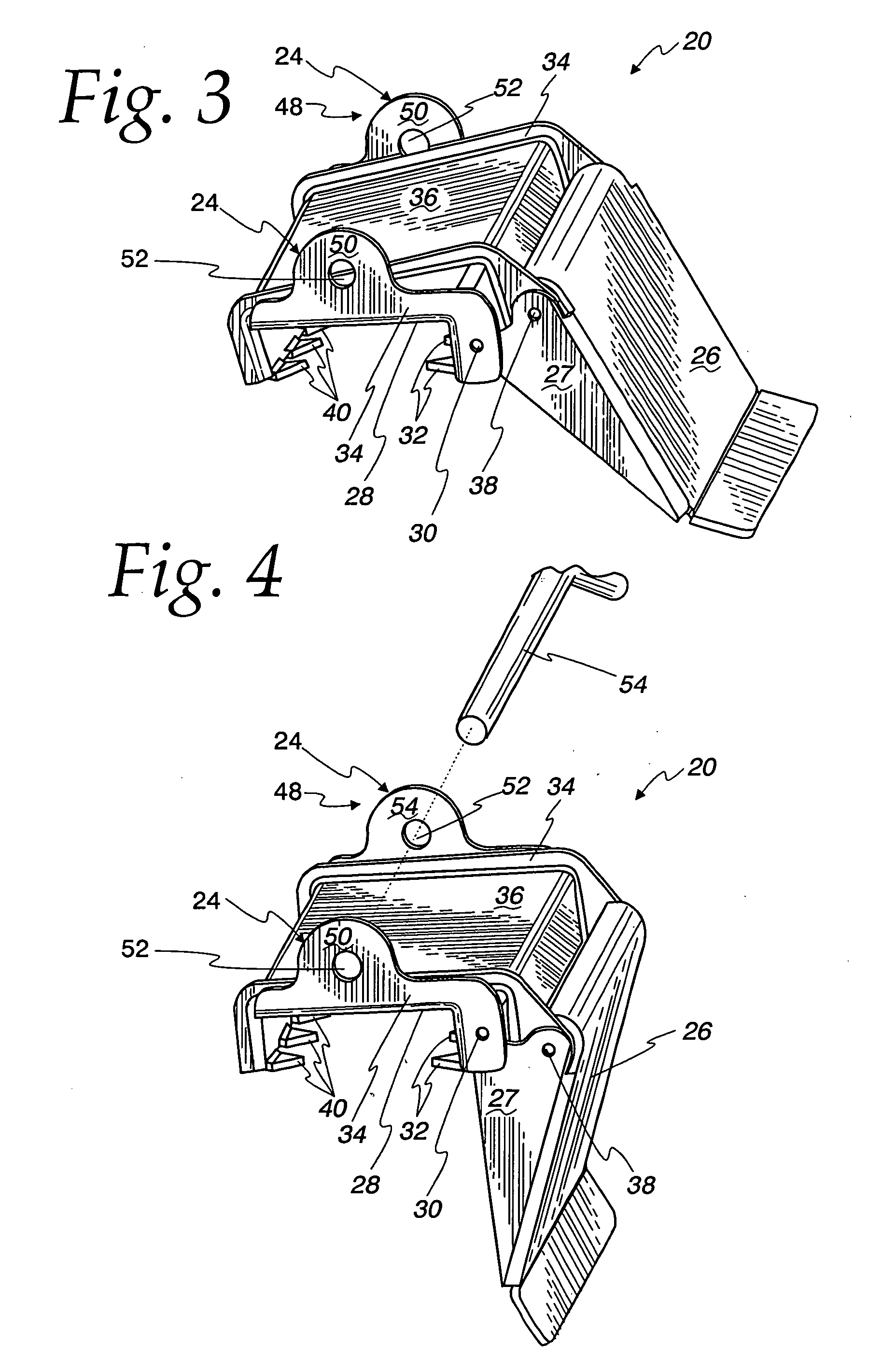

[0065] In the following detailed description of drawings the same reference numeral will be used to identify the same or similar elements in each of the figures. FIGS. 1 through 4 illustrate a mounting clip 20 in accordance with the present invention. The mounting clip 20 generally includes a clamp 22 and one or more accessory mount 24. The clamp 22 in the illustrated embodiment includes a lever 26, a base plate 28 joined to the lever 26 by a hinge 30, and a clamping jaw 36 joined to the lever 26 by another hinge 38. FIGS. 1 through 4 illustrate the mounting clip 20 moving from an opened position (FIG. 1), through intermediate positions (FIGS. 2 and 3), to a closed position (FIG. 4).

[0066] The illustrated lever 26 has triangular flanges 27, which provide a location for connecting the base plate hinge 30 and the clamping jaw hinge 38 to the lever. The two hinges 30 and 38 are spaced apart to provide sufficient leverage to secure the mounting clip 20 to a stud 56.

[0067] The base pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com