Shunt for a web divided into several sectional webs

a sectional web and web technology, applied in the field of webs, can solve the problems of inaccurate lead of sectional webs and increase the problem of webs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

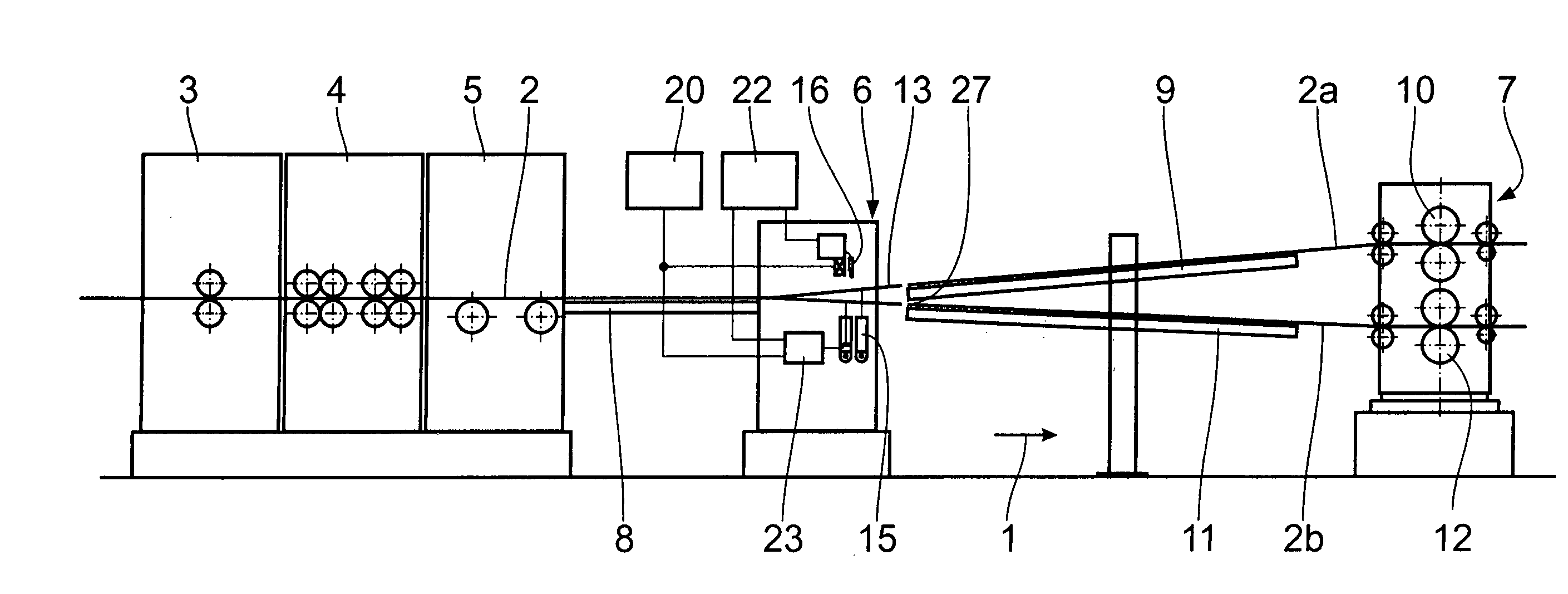

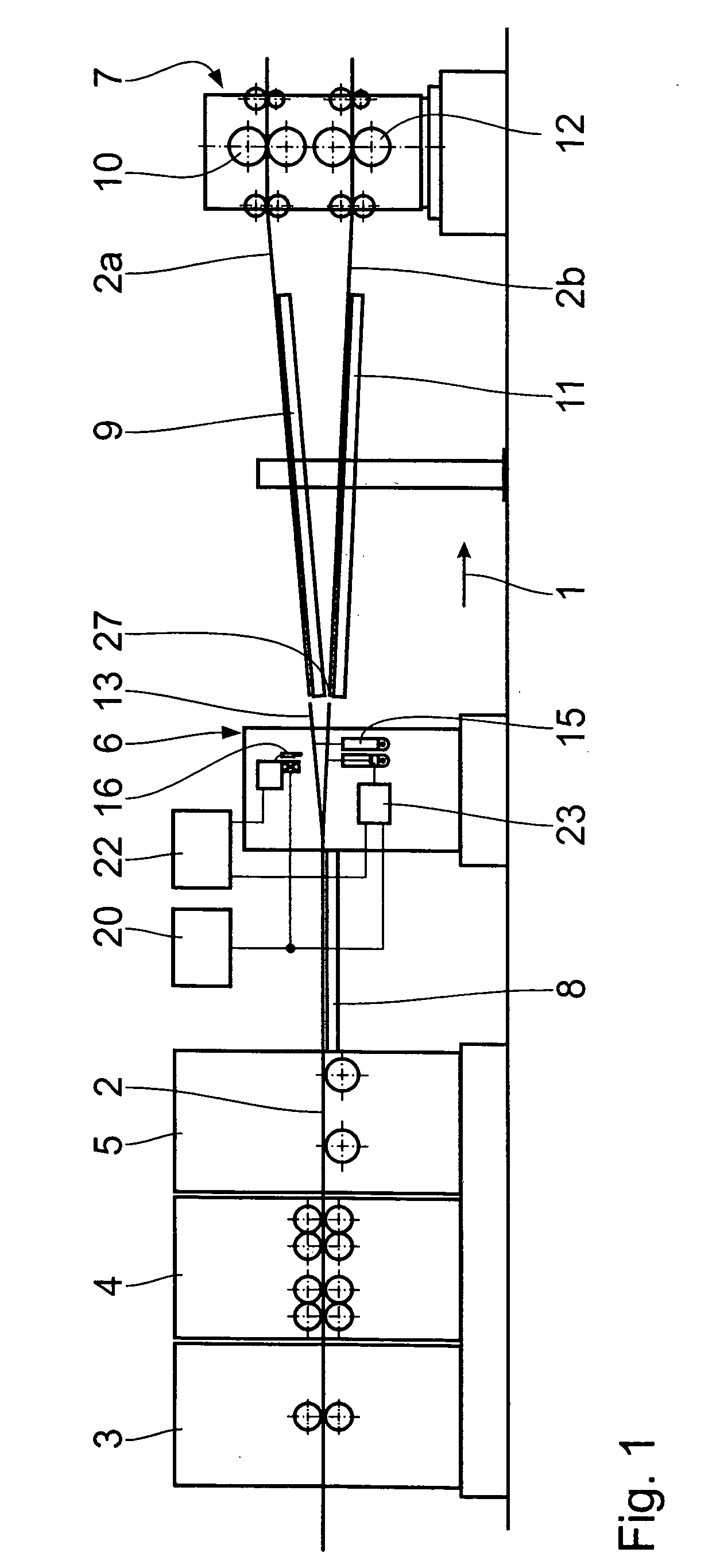

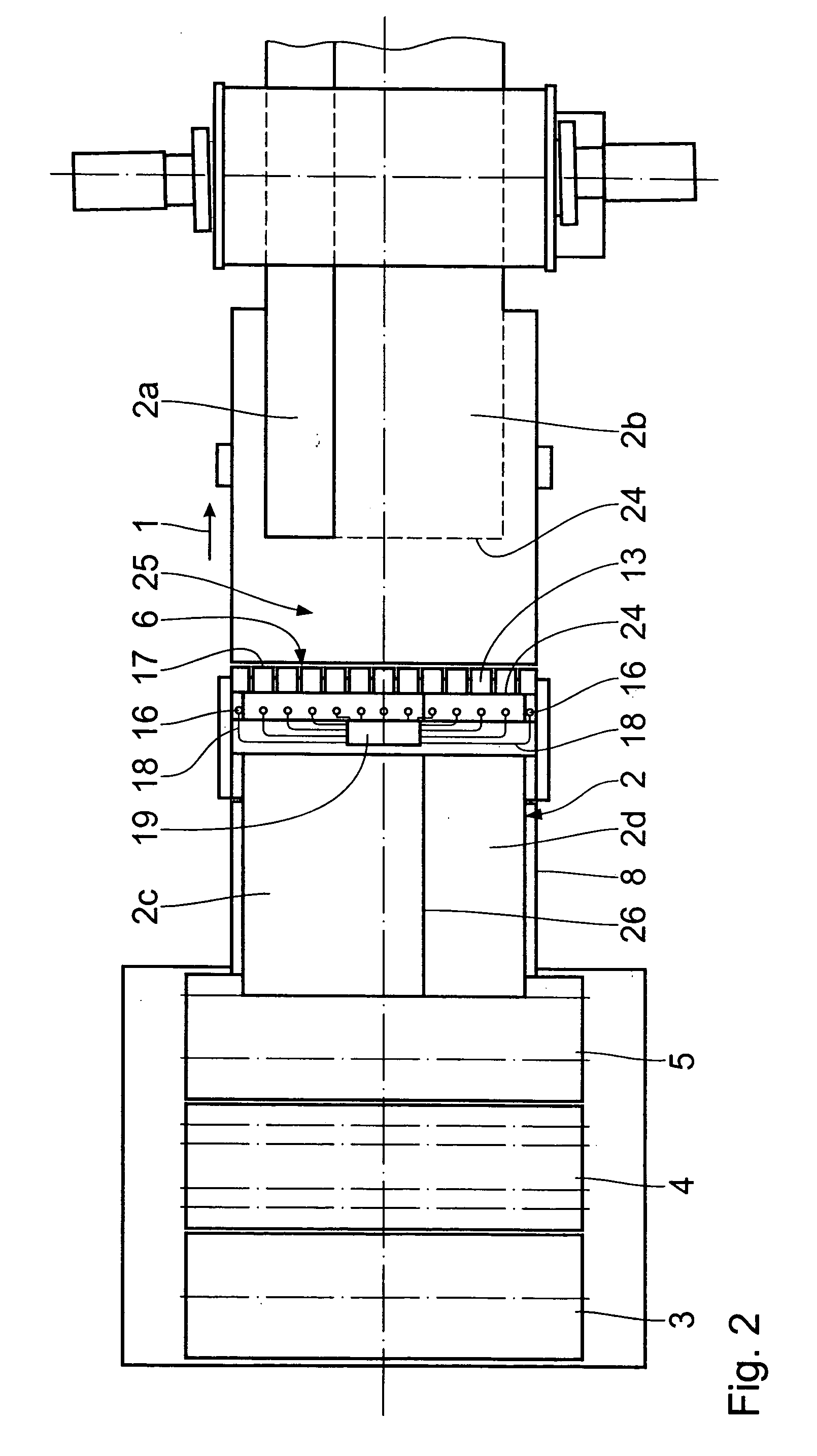

[0013] Seen in the conveying direction 1 of a web of corrugated board 2, the part of a corrugating machine illustrated in the drawing successively comprises a short cross cutter 3, a corrugating unit 4, a longitudinal cutter 5, a shunt 6 and a duplex cross cutter 7. A transfer table 8 is provided between the longitudinal cutter 5 and the shunt 6. Two tables, one on top of the other, are provided between the shunt 6 and the duplex cross cutter 7, a top table 9 of which leading to the top cross cutter 10 of the duplex cross cutter 7 and a bottom table 11 leading to the bottom cross cutter 12 of the duplex cross cutter 7. The shunt 6 includes shunting elements 13 of the type of so-called blades. These blades 13 are comprised of parallel, side by side bars of a width of for instance approximately 10 cm crosswise of the conveying direction 1, which are pivoted about a joint pivoting axis 14 that is located in vicinity to the table 8. By means of a linear drive, for example a pneumaticall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com