Gloves with easily deployed cuff catcher

a technology of gloves and cuffs, which is applied in the field of gloves, can solve the problems of liquids likely continuing to run onto the arm, water dripping from gloves onto the arm,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

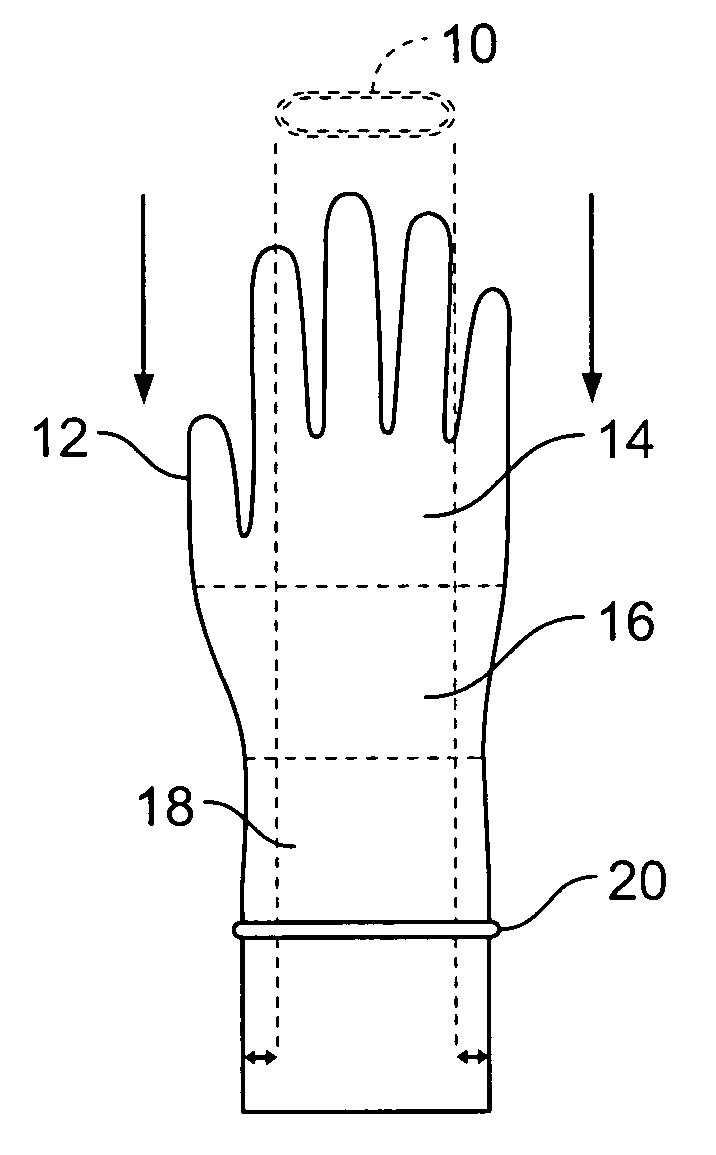

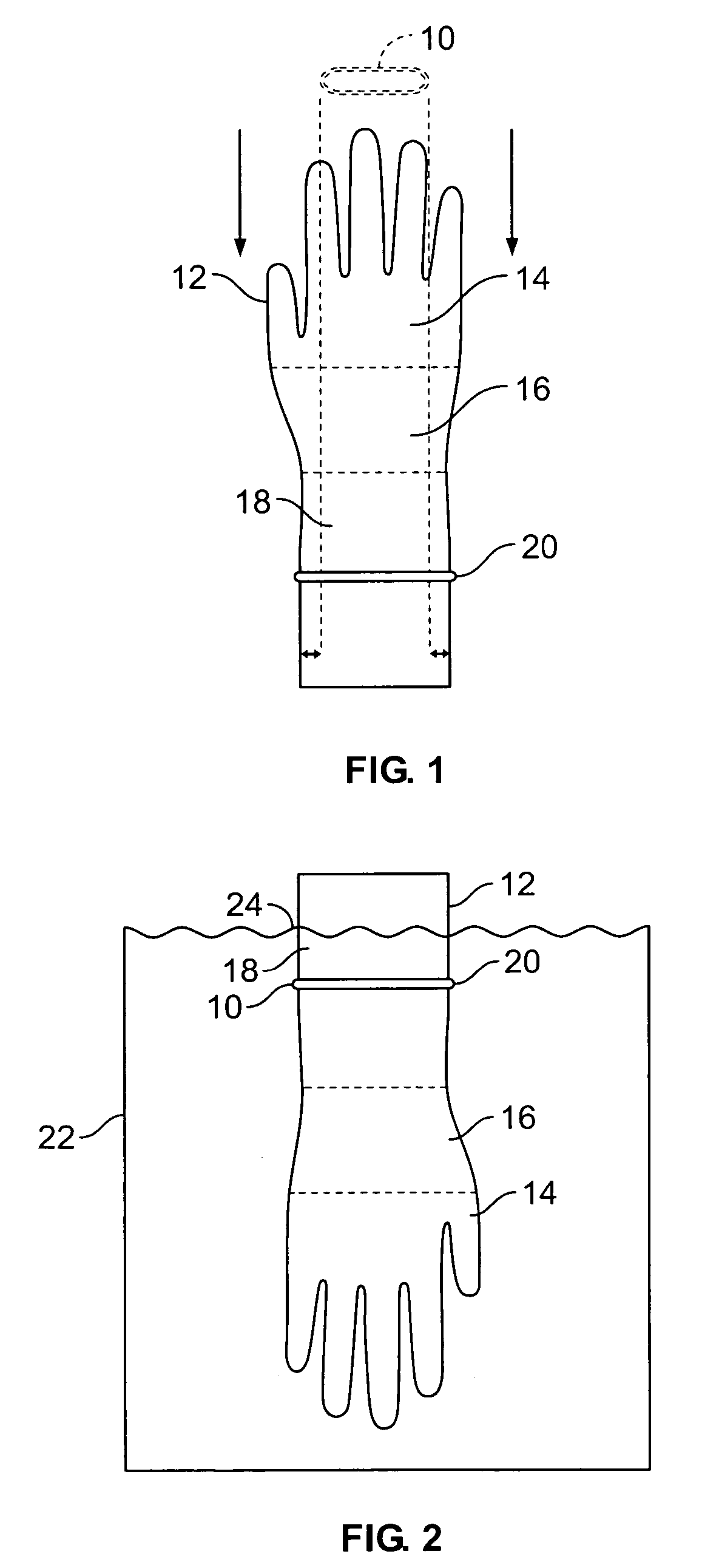

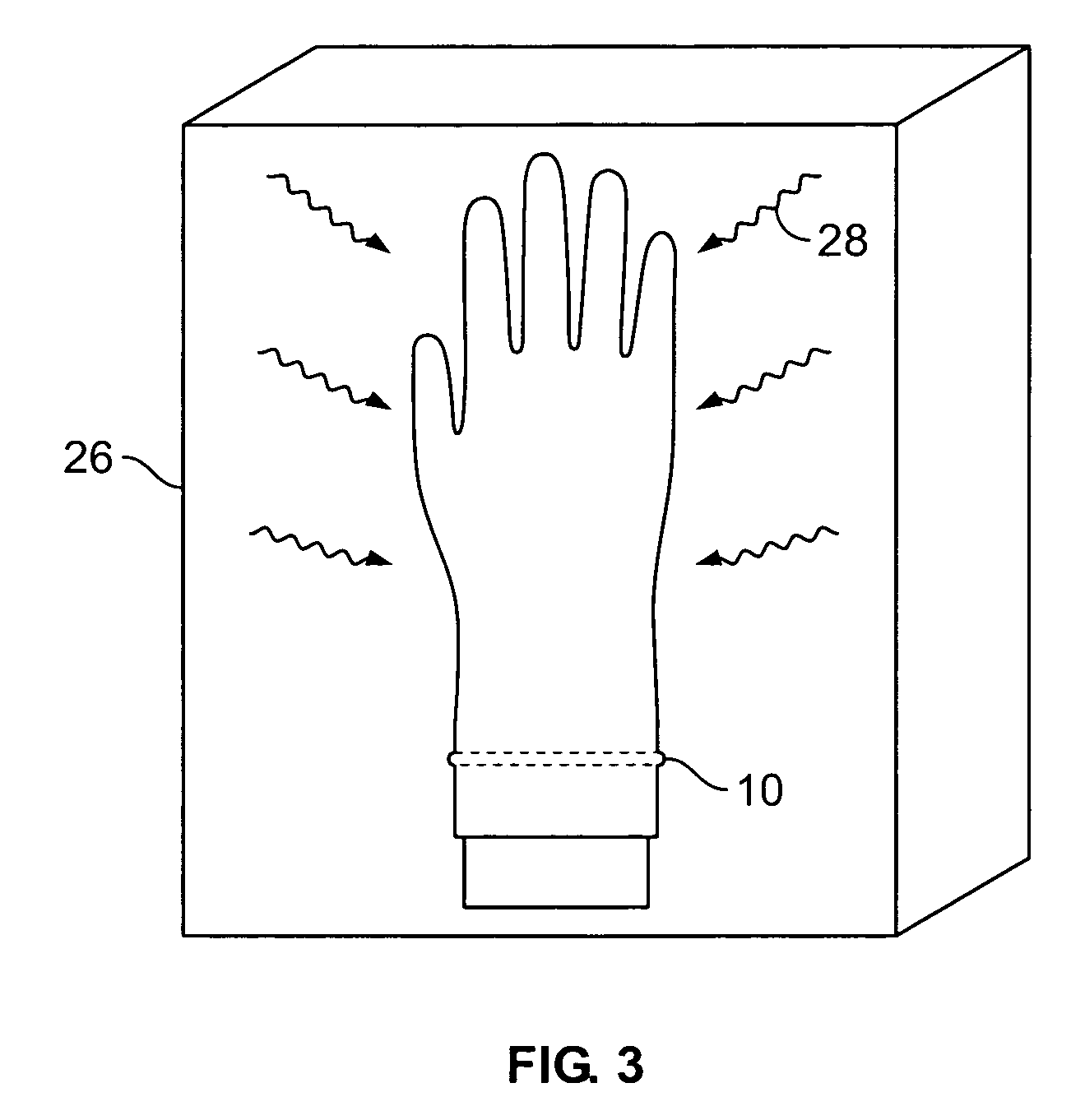

[0026]FIGS. 1 through 4 depict the process of manufacturing a rubber glove on a conventional former according to the first illustrative embodiment of the present invention. In FIG. 1, a conventional ceramic former 12 has a finger portion 14, palm portion 16, and a cuff portion 18. An elastomeric band 10 is placed around the conventional ceramic former 12 at a position 20 between the ends of the cuff portion 18. The elastomeric band 10 can be made of the same material as the rubber glove to be formed or can be of another elastic or elastomeric material, such as a rubber band. Preferably, the elastomeric band 10 is partially vulcanized so as to allow the elastomeric band 10 to sufficiently adhere to a coating of latex rubber to be applied to the former 12. The elastomeric band 10 has a diameter that requires it to be stretched in order to apply it to the former 12 at position 20. Once applied to the former 12, the elastomeric band 10 is under tension during the glove forming process. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| elastomeric | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com