Golf club head

a golf club and club head technology, applied in golf clubs, racket sports, textiles and paper, etc., can solve the problems of difficult to impart spin to a hit ball, easy damage to the surface of the iron head, etc., and achieve the effect of superior ball-hit feeling and abrasion resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

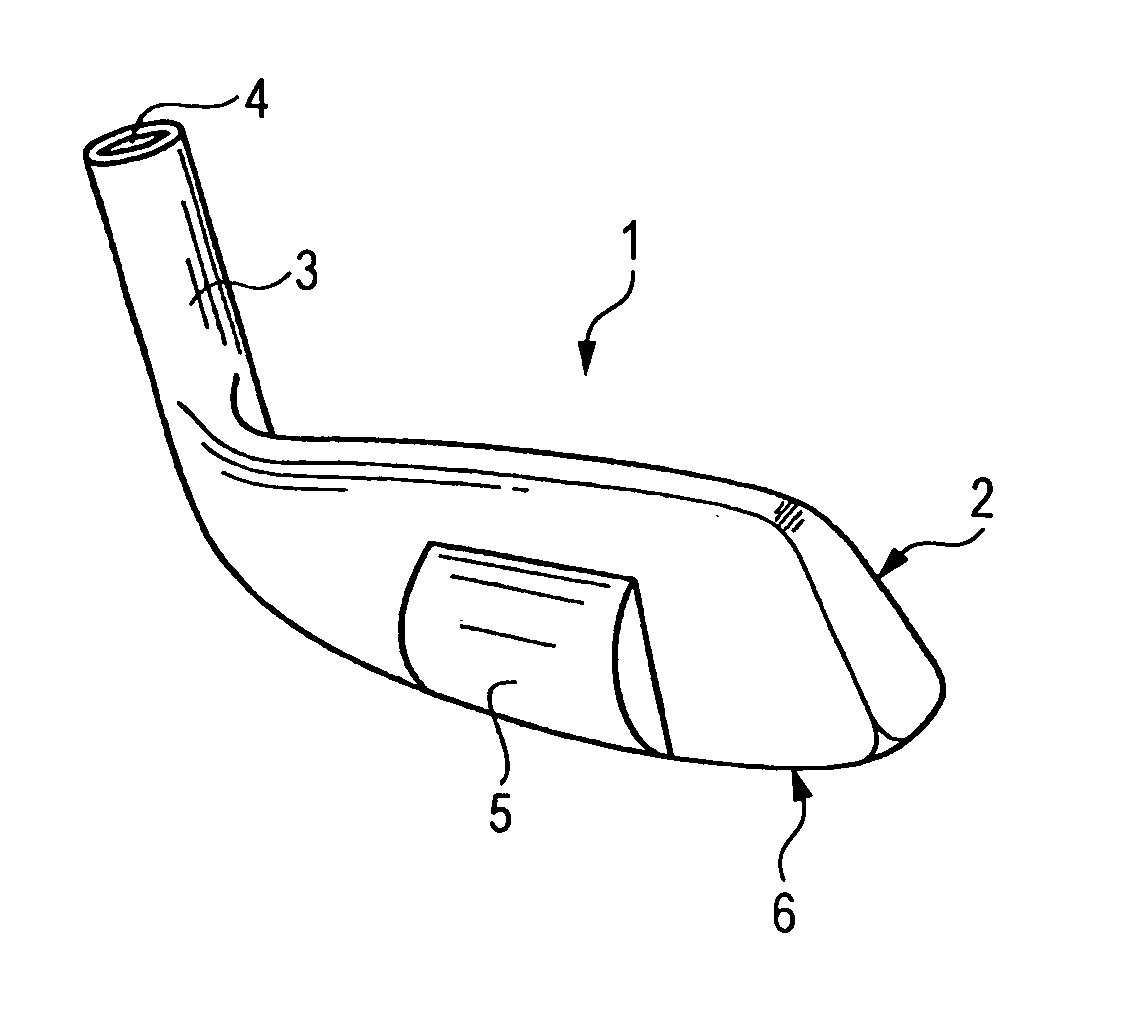

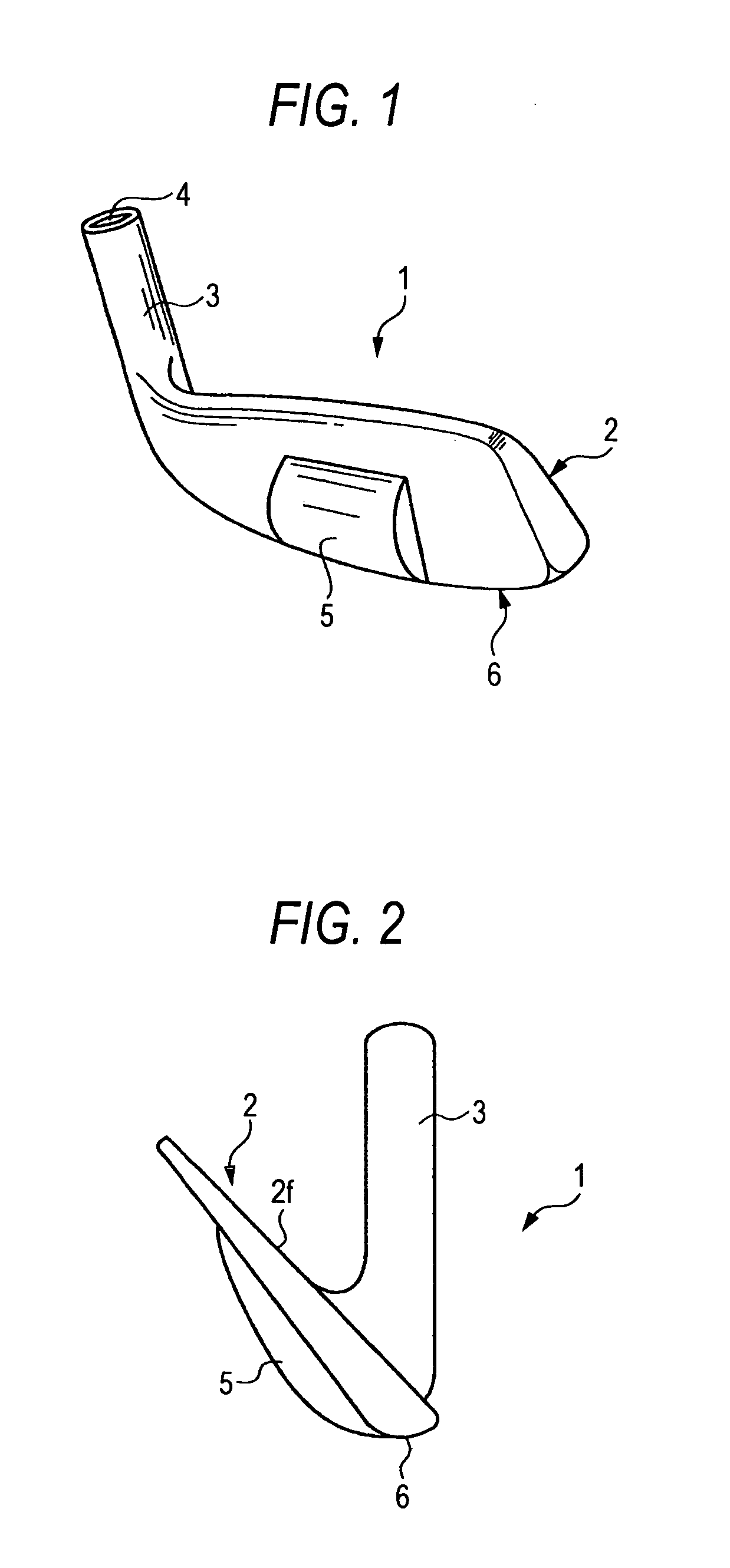

[0027] Hereinafter, the invention will be described further in detail by reference to the drawings. FIG. 1 is a perspective view of a golf club head according to an embodiment of the invention, as viewed from the rear. FIG. 2 is a side view of the same as viewed from the toe side thereof.

[0028] An iron-type golf club head 1 has a face 2 which has a face surface 2f of a flat shape, and a hosel 3 which is continuous with the face 2 on its heel side. A shaft insertion hole 4 is disposed in the hosel 3. A tip of a golf club shaft is inserted into the shaft insertion hole 4, and fixedly attached thereto by means of an adhesive.

[0029] The golf club head 1 shown in the drawings is a wedge whose loft angle is 45°. On the backside of the golf club head 1, a protrusion 5 protruding rearward in the vicinity of the center in a toe-heel direction is disposed. The face 2 is substantially uniform in thickness, except for the protrusion 5.

[0030] Meanwhile, the face 2 has its greatest thickness a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com