Flow device

a flow device and flow technology, applied in flow mixers, special dispensing means, electrolysis, etc., can solve the problems of shrinkage of polymeric compositions, difficulty in changing the surface chemistry of packing materials after they have been placed in channels,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples 1-3

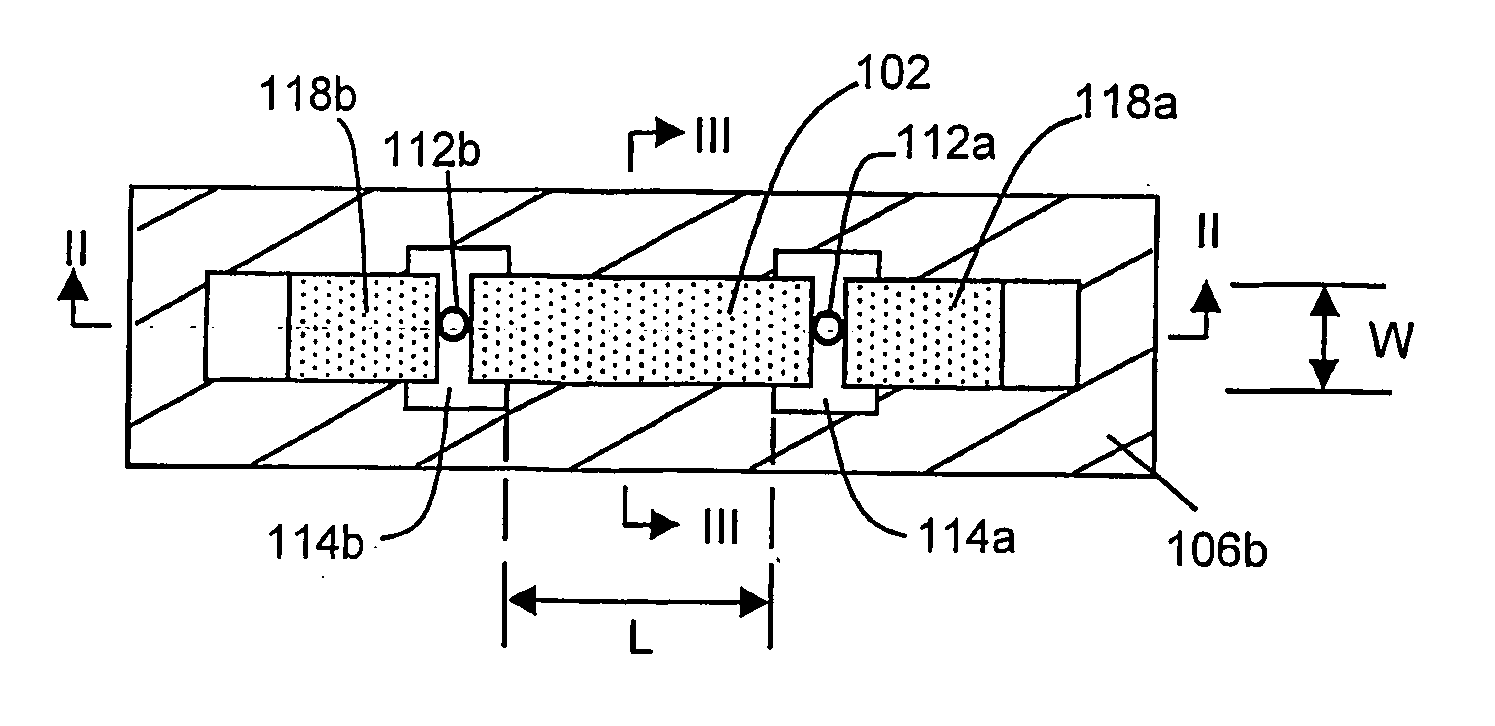

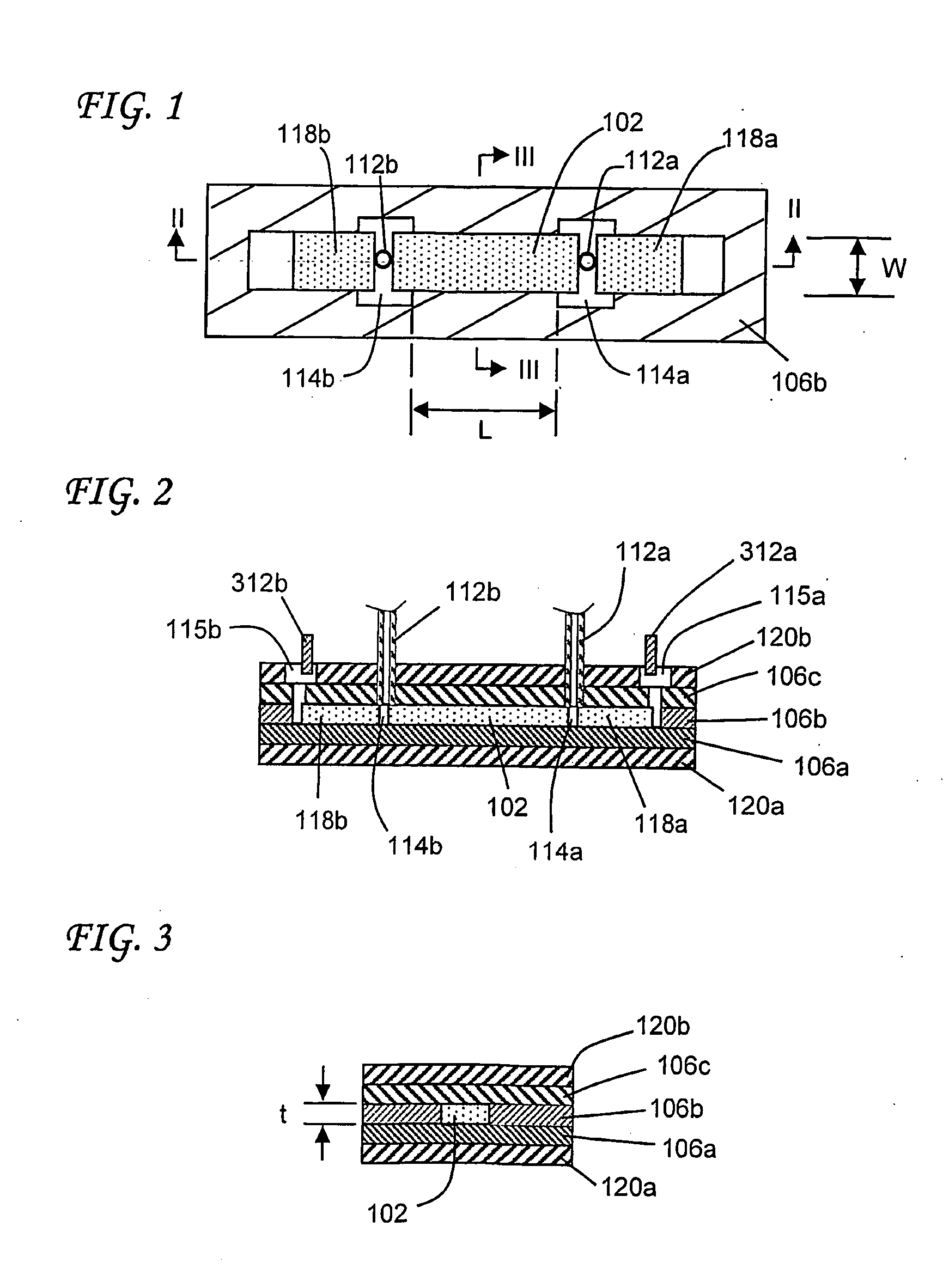

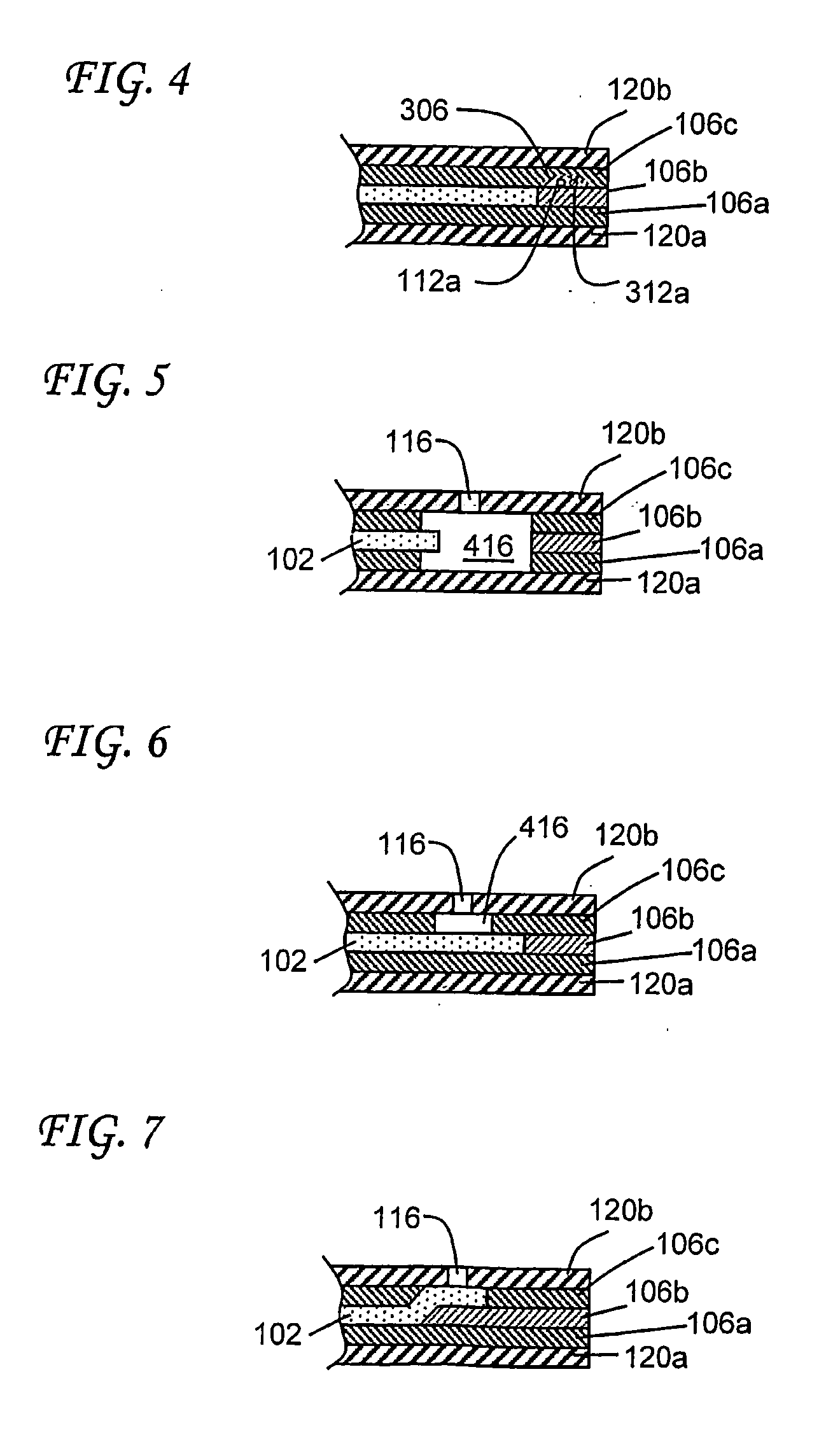

[0138] Three devices as illustrated in FIG. 19 were constructed using first and second PFMs having the characteristics shown in the Table below, the dimensions of L, w and t being in mm. In each Example, the effective pore size of the first PFM was 240 nm and the effective pore size of the second PFM was 300 nm.

First PFMSecond PFMExample #LwtZetaLwtZeta11050.1+50102.10.12−3021050.1+50580.2+23102.30.1−358.752.30.09+27

example 4

[0139] A mixing device as shown in FIGS. 23-25 was prepared. The dimensions of the device, as identified in FIGS. 23-25 and given in mm, are shown in the table below. Each of the PFMs was a hydrophilic PVDF membrane having effective pore size of about 800 nm. The mixing member was a hydrophilic PVDF membrane having an effective pore size of about 6000 nm and a thickness of 0.1 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com