Easily assembled and repairable plastic shipping pallet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] (Added) This section was added to get a better understanding on how to put together and take apart this repairable plastic pallet.

Assembly of the Repairable Plastic Pallet:

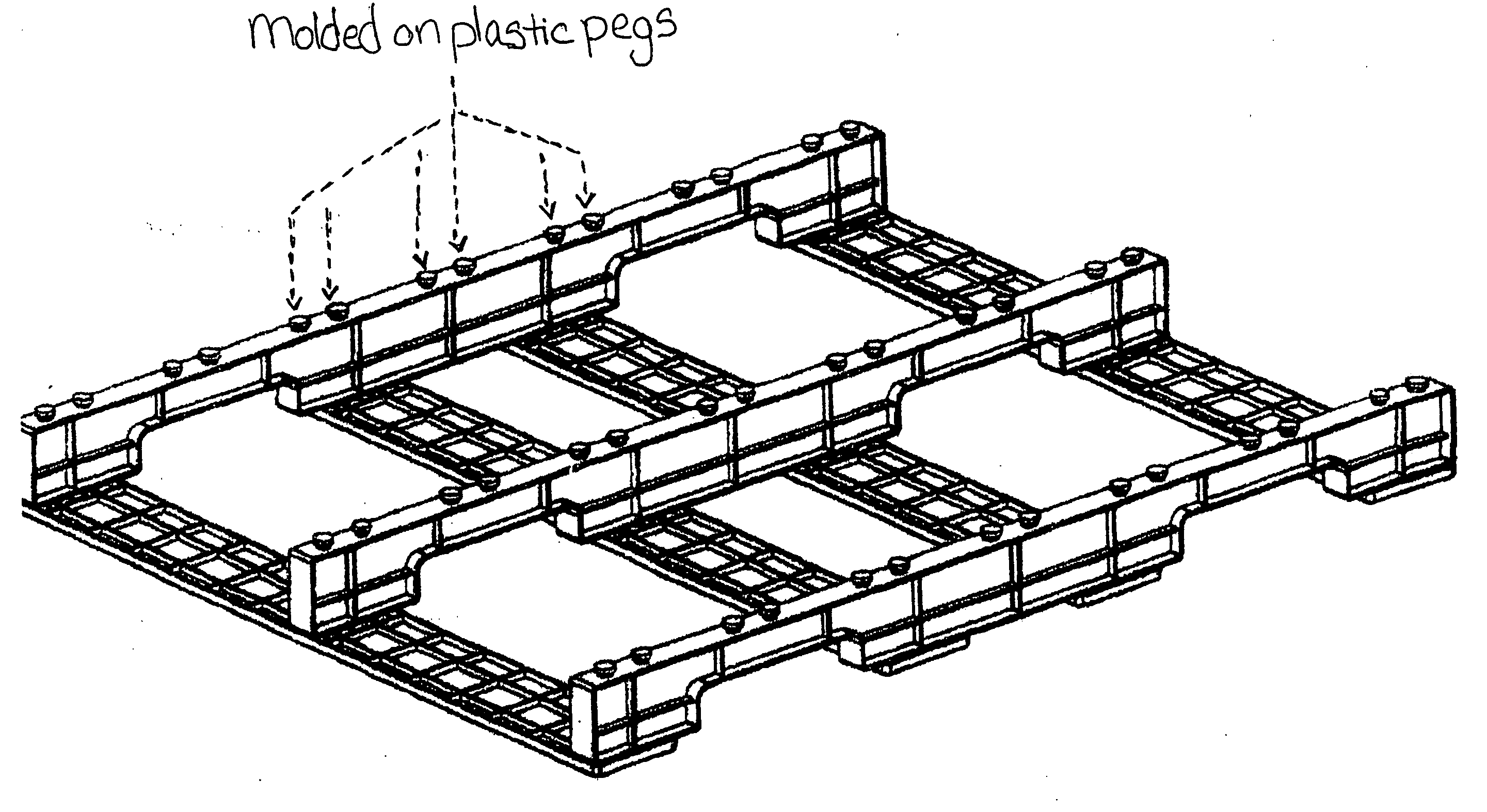

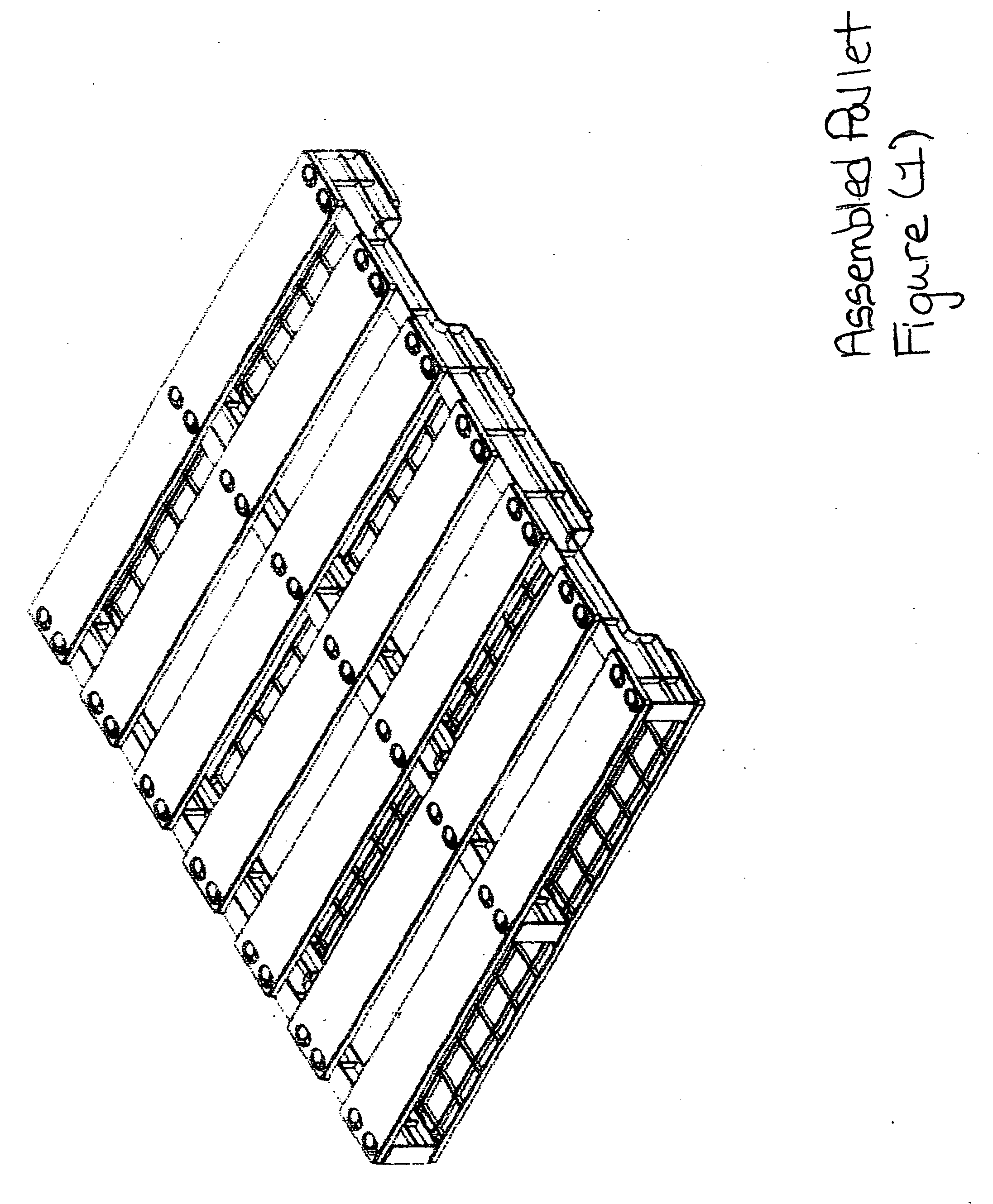

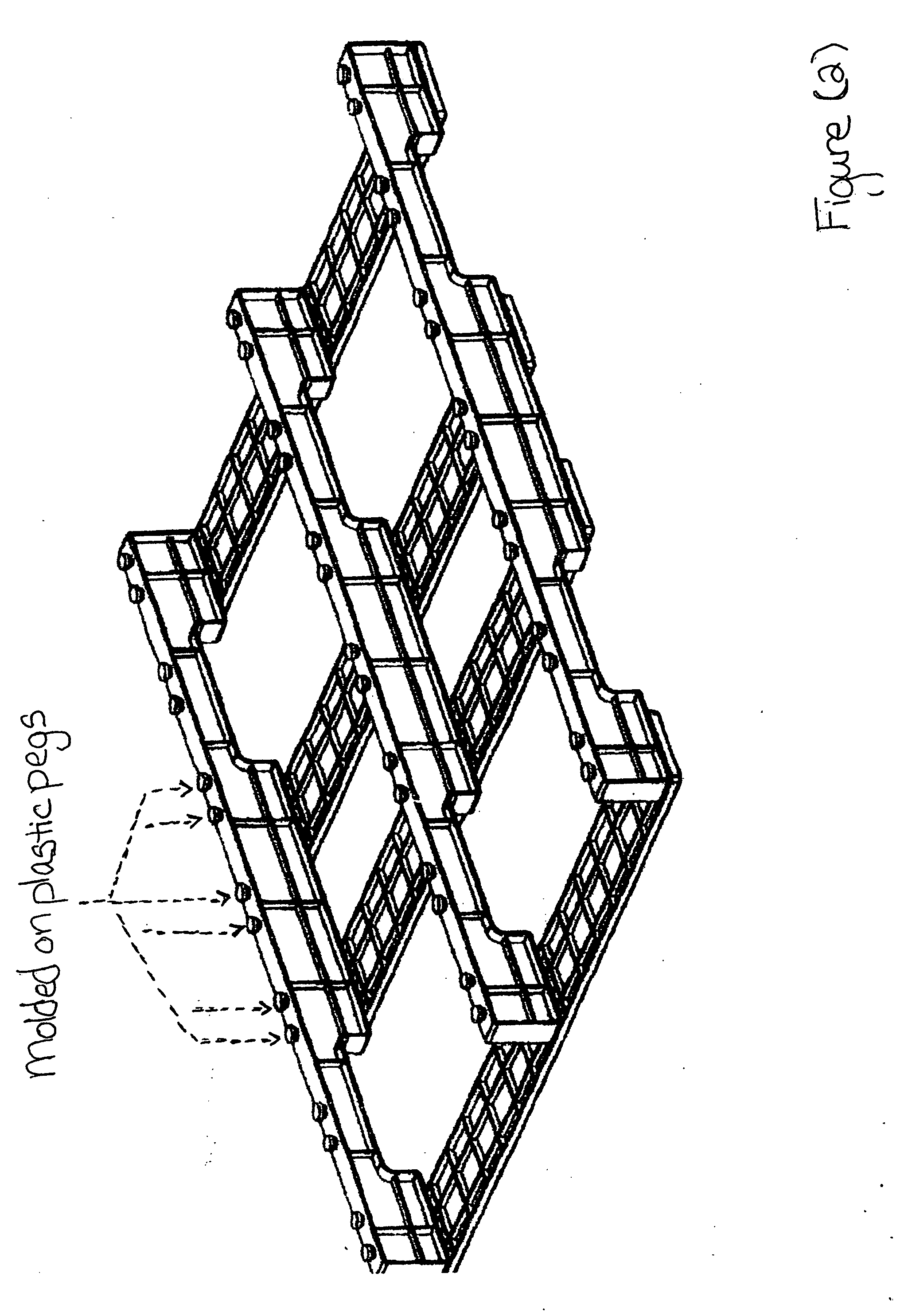

[0018]“Board / Slat (FIG. 6) will be used in conjunction with runner / rail (FIG. 4) to form an assembled pallet (FIG. 1)”.

[0019] Step 1: Refer to Drawing (FIG. 4) of a Runner / Rail. [0020] A. “I suggest assembling bottom side first”. Take 3 runner / rails (FIG. 4) placing on a flat surface notch side up. [0021] B. Be sure pegs are facing in same direction. [0022] C. Only on one end of each runner / rail, the first 2 pegs are turned in opposite direction than the others. (When the board (FIG. 6) is mounted this prevents the jarring loose caused by a the entrance of a forklift or pallet jack).

[0023] Step 2: Refer to Drawing (FIG. 6) of a Board / Slat. [0024] A. The board / slat (FIG. 6) will only go on in one direction. [0025] B. Place the board / slat (FIG. 6) on the runner / rail (FIG. 4). [0026] C. At this point the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com