Cover for dispensing closure with pressure actuated valve

a technology of valve head and valve cover, which is applied in the field of containers and closures, can solve problems such as restricting the movement of the valve head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

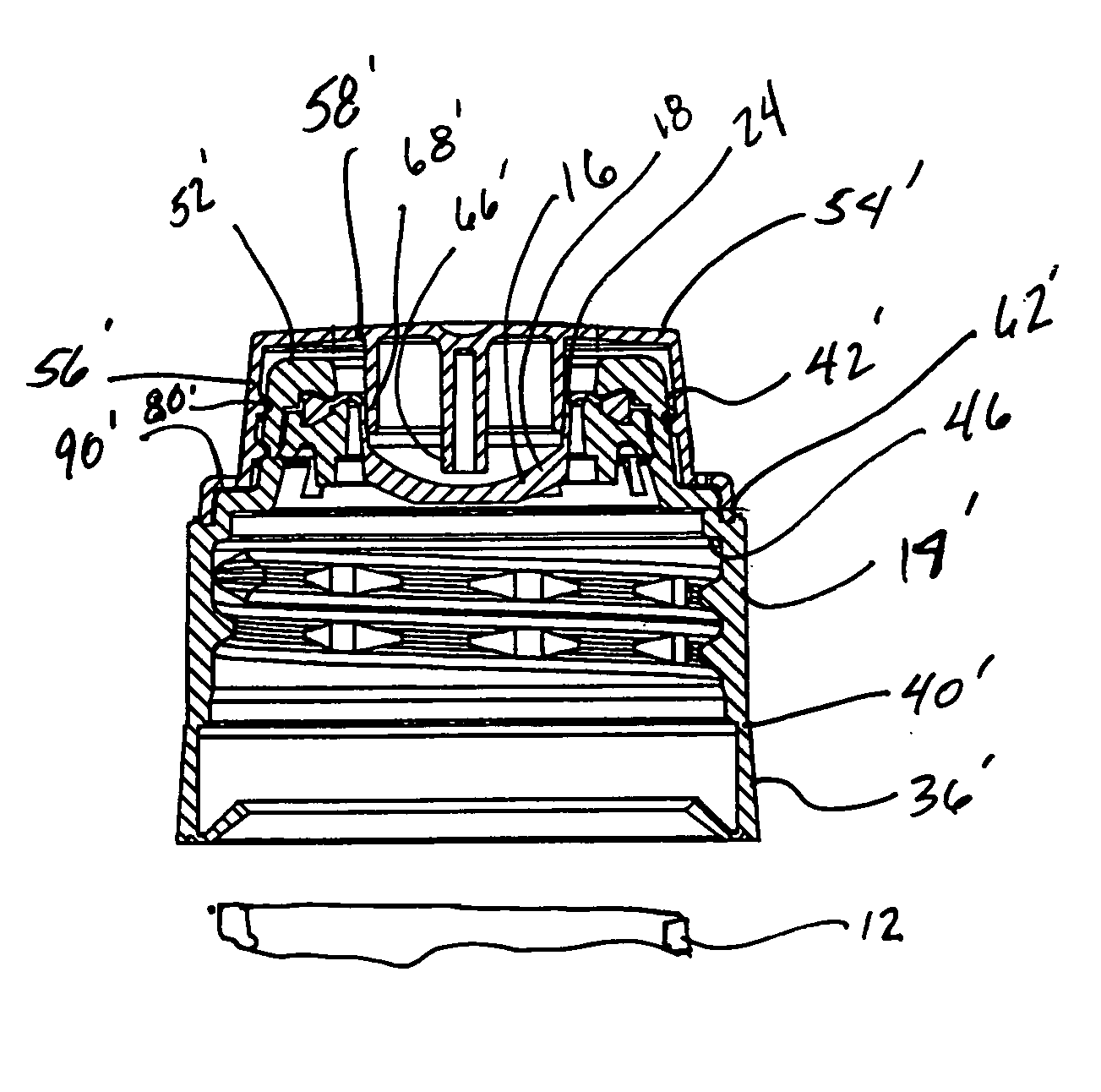

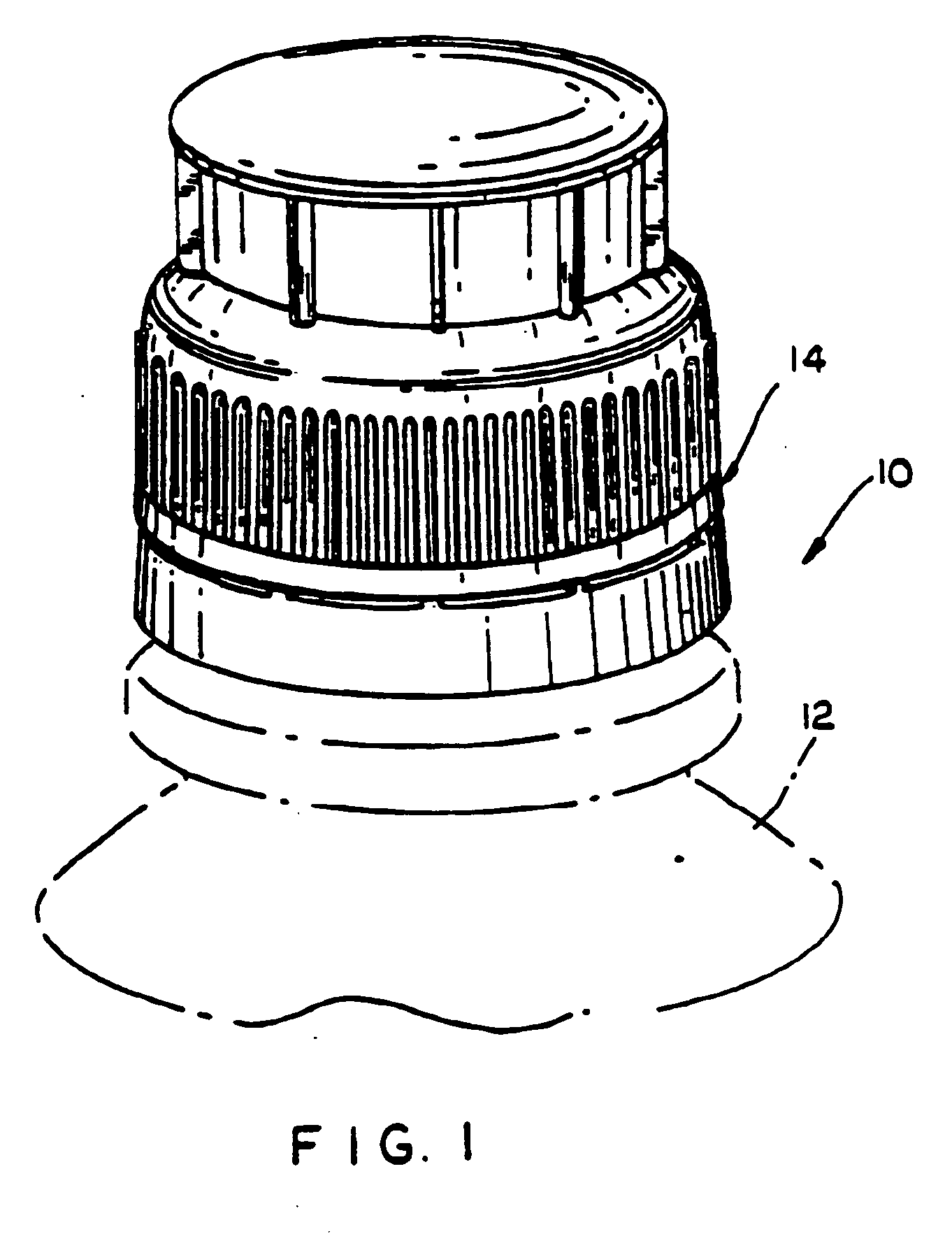

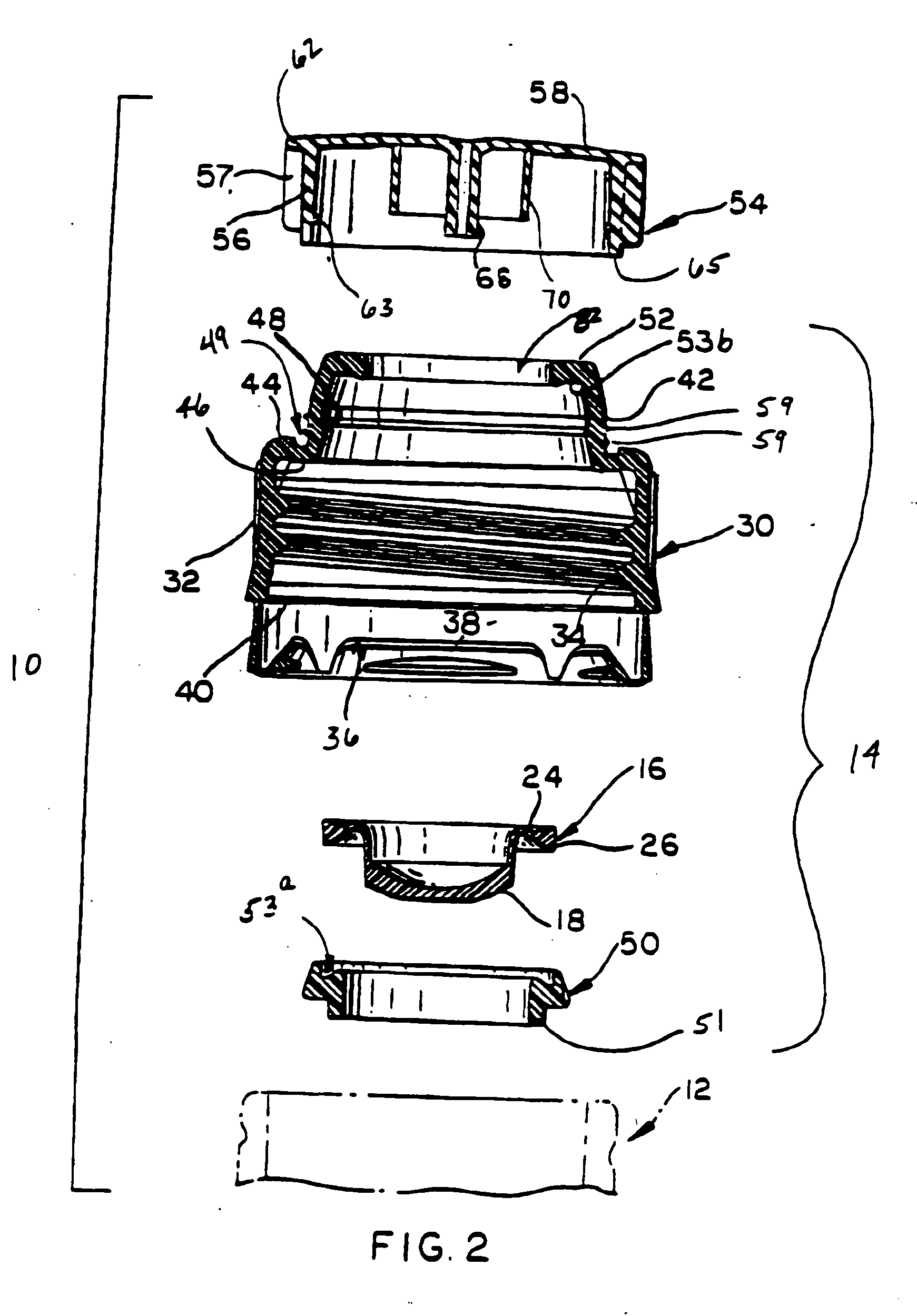

[0021] As shown in FIGS. 7 and 8, a conventional dispensing package includes a container 12 (shown schematically in FIGS. 7 and 8), a valved dispensing closure 14, and a cover 101, each of which is more fully described in U.S. Pat. No. 6089418, which is assigned to the present assignee. The valved dispensing closure 14 includes a self-sealing dispensing valve 16, a base 30, and a retaining ring 50, as shown in FIGS. 7 and 8, and in the lower portion of FIG. 2. Valve 16 comprises a one-piece, integrally-molded member preferably constructed from liquid silicone rubber, or the like. Valve 16 includes a concave valve head 18 with cross-slits 20 defining pie shaped flaps 22 and a discharge orifice therein. Cross-slits 20 and flaps 22 are best shown in FIG. 6.

[0022] A connector sleeve 24 has one end connected with the marginal circumferentially extending flange 26, which is substantially triangular in cross section, and the opposite end connected with valve head 18 adjacent to this margi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com