Two-piece structure including a blow-molded plastic portion

a two-piece structure and plastic portion technology, applied in the direction of sports equipment, etc., can solve the problems of inability to support a desired amount of weight, heavy and difficult to move tables, and insufficient strength of tables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

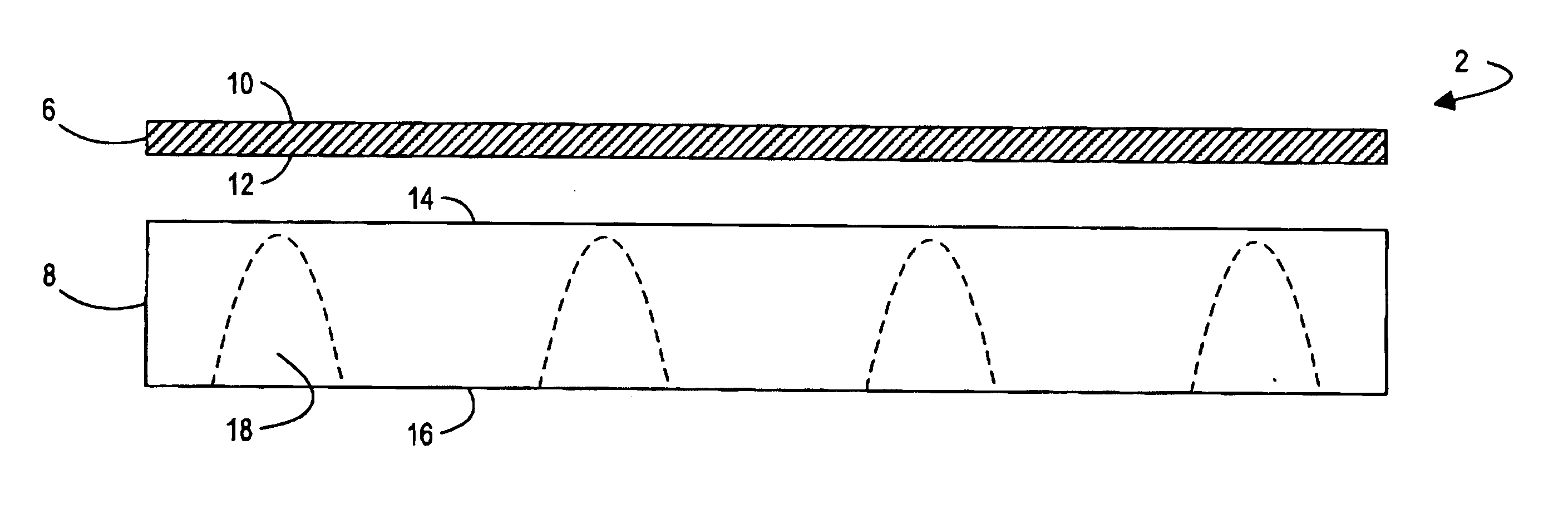

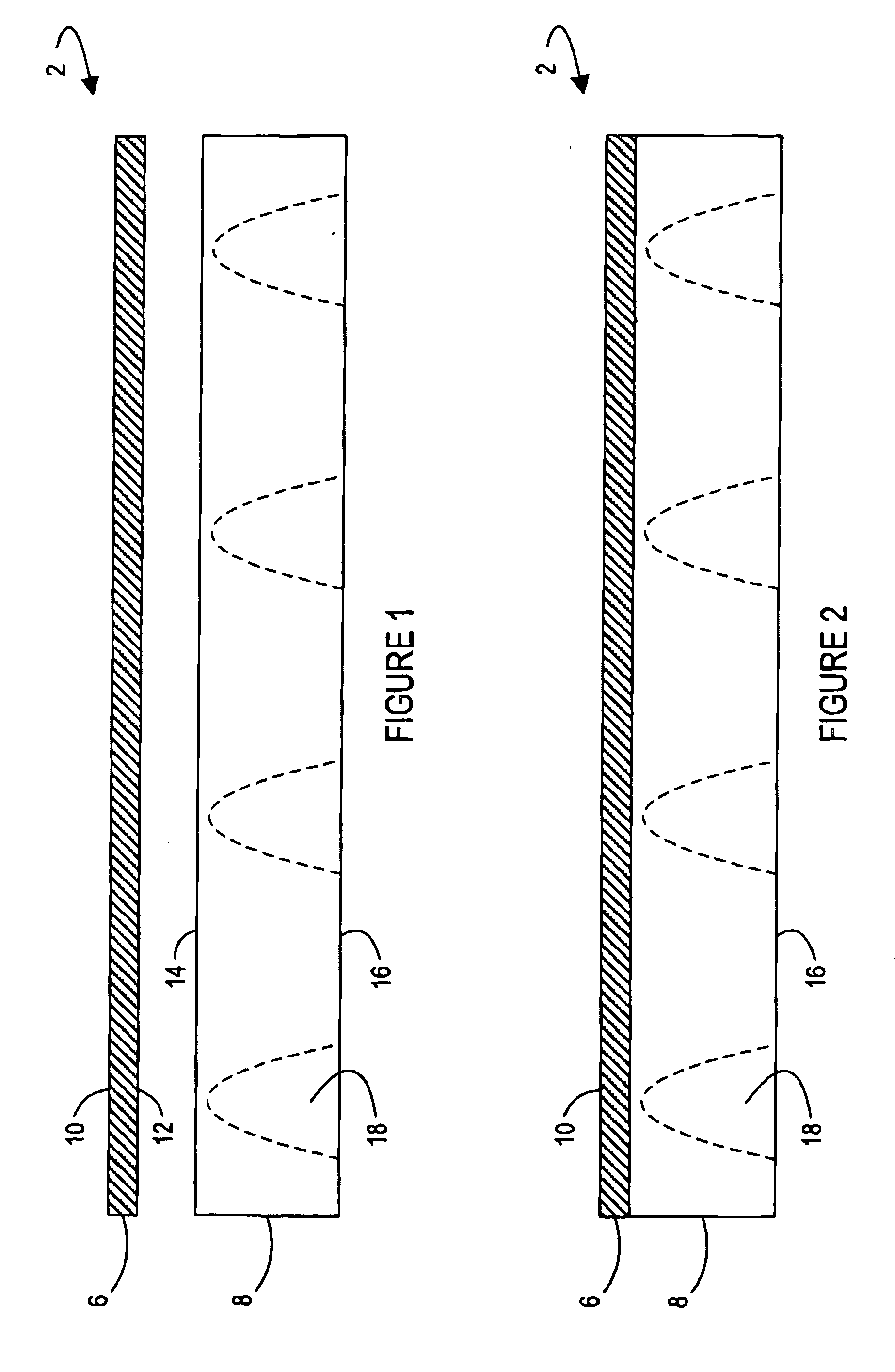

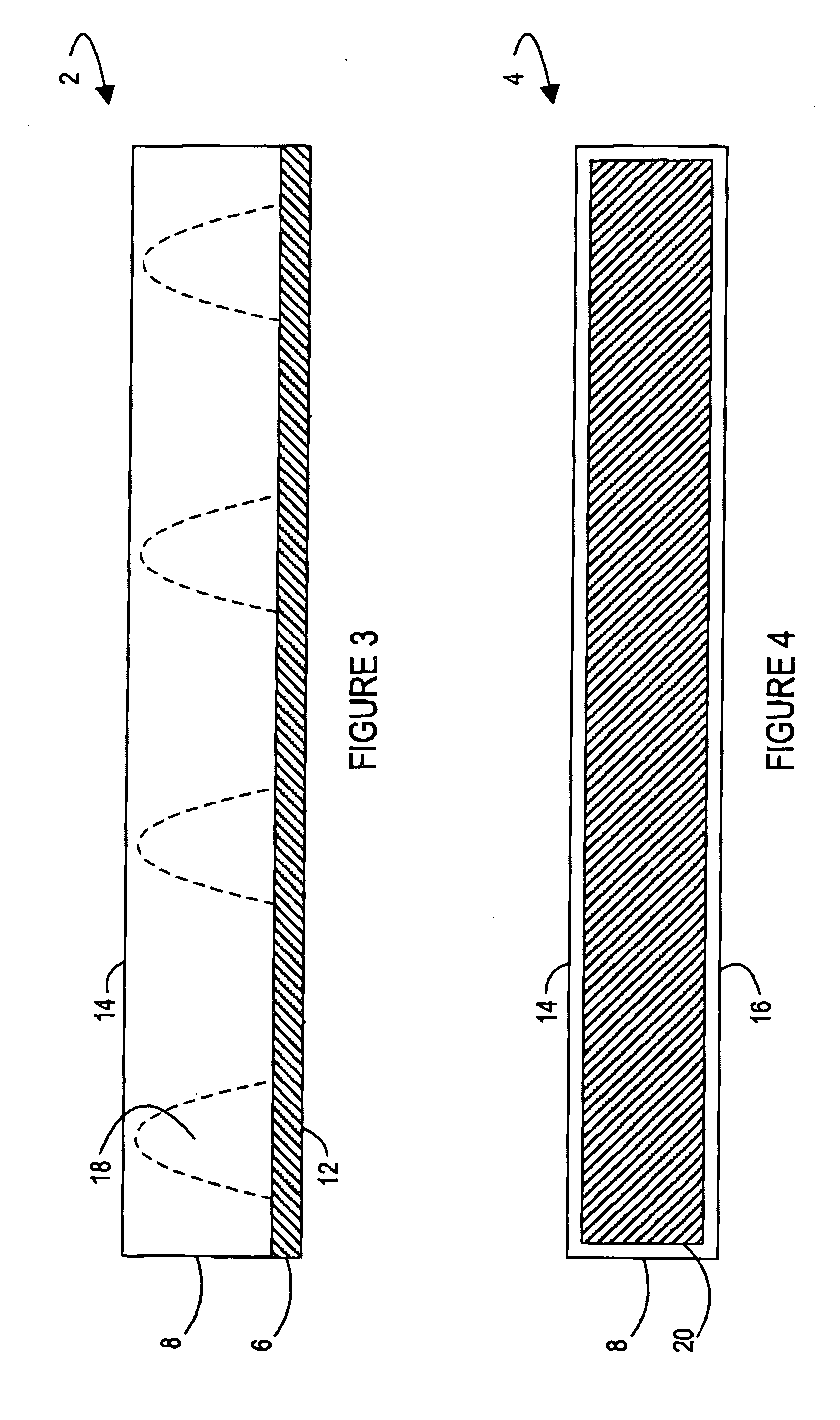

[0029] The present invention is generally directed towards a structure including at least a portion that is constructed from blow-molded plastic, such as a table-tennis top. The principles of the present invention, however, are not limited to table-tennis tables. It will be understood that, in light of the present disclosure, the exemplary embodiments disclosed herein can be successfully used in connection with other types of tables, furniture and structures.

[0030] To assist in the description of the table-tennis top, words such as top, bottom, front, rear, right and left may be used to describe the accompanying figures. It will be appreciated, however, that the table-tennis top can be located in a variety of desired positions. It will also be understood that the drawings are not intended to limit the present invention and the drawings are not necessarily drawn to scale. A detailed description of the table-tennis top now follows.

[0031] As shown in FIG. 1, an exemplary table-tennis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com