Retaining wall with plastic coated wooden panels

a technology of retaining walls and wooden panels, applied in the direction of walls, construction, building components, etc., can solve the problems of rot and deterioration, wooden panels are subject to deterioration, and the process of deterioration is not easy to achiev

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

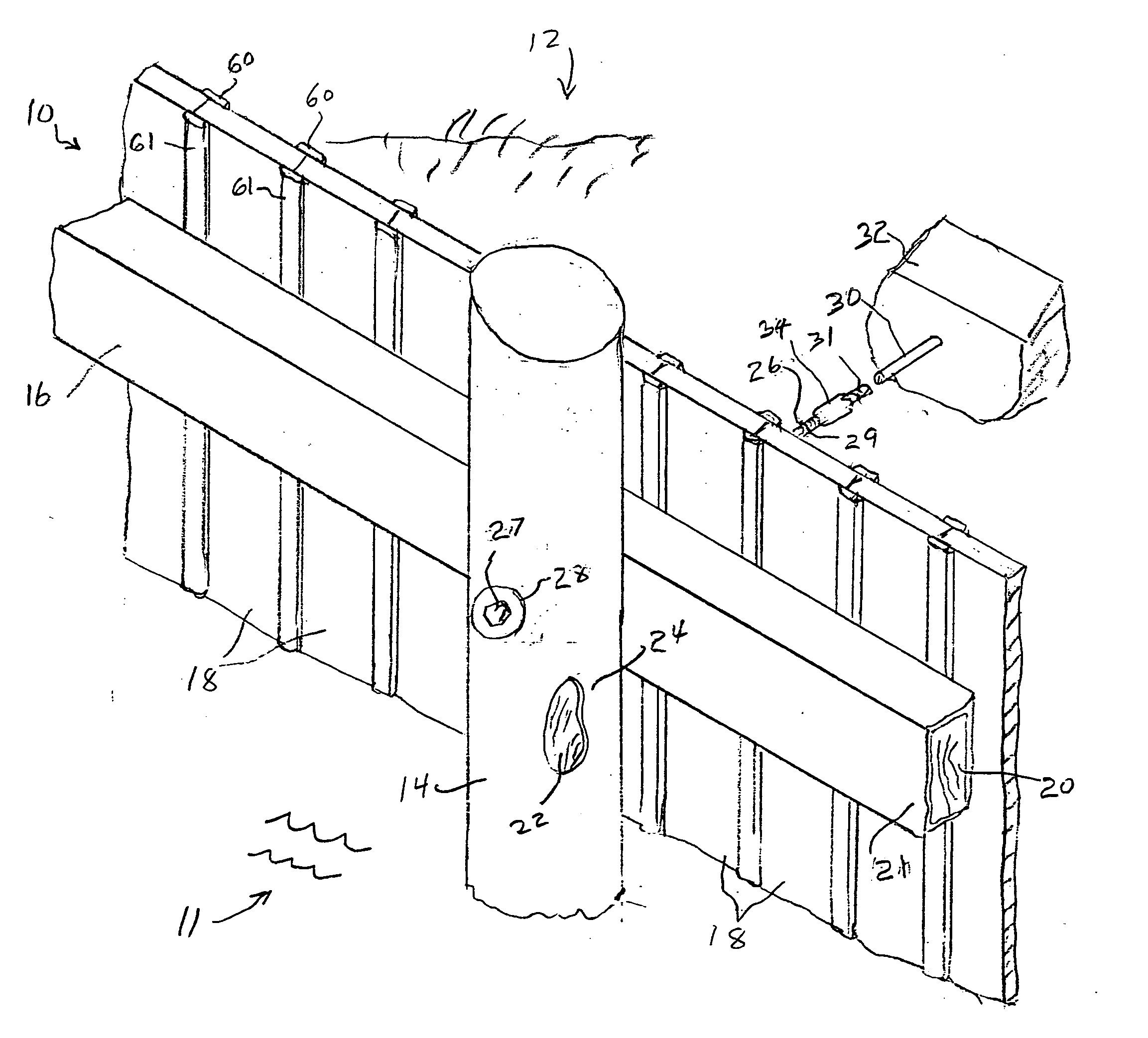

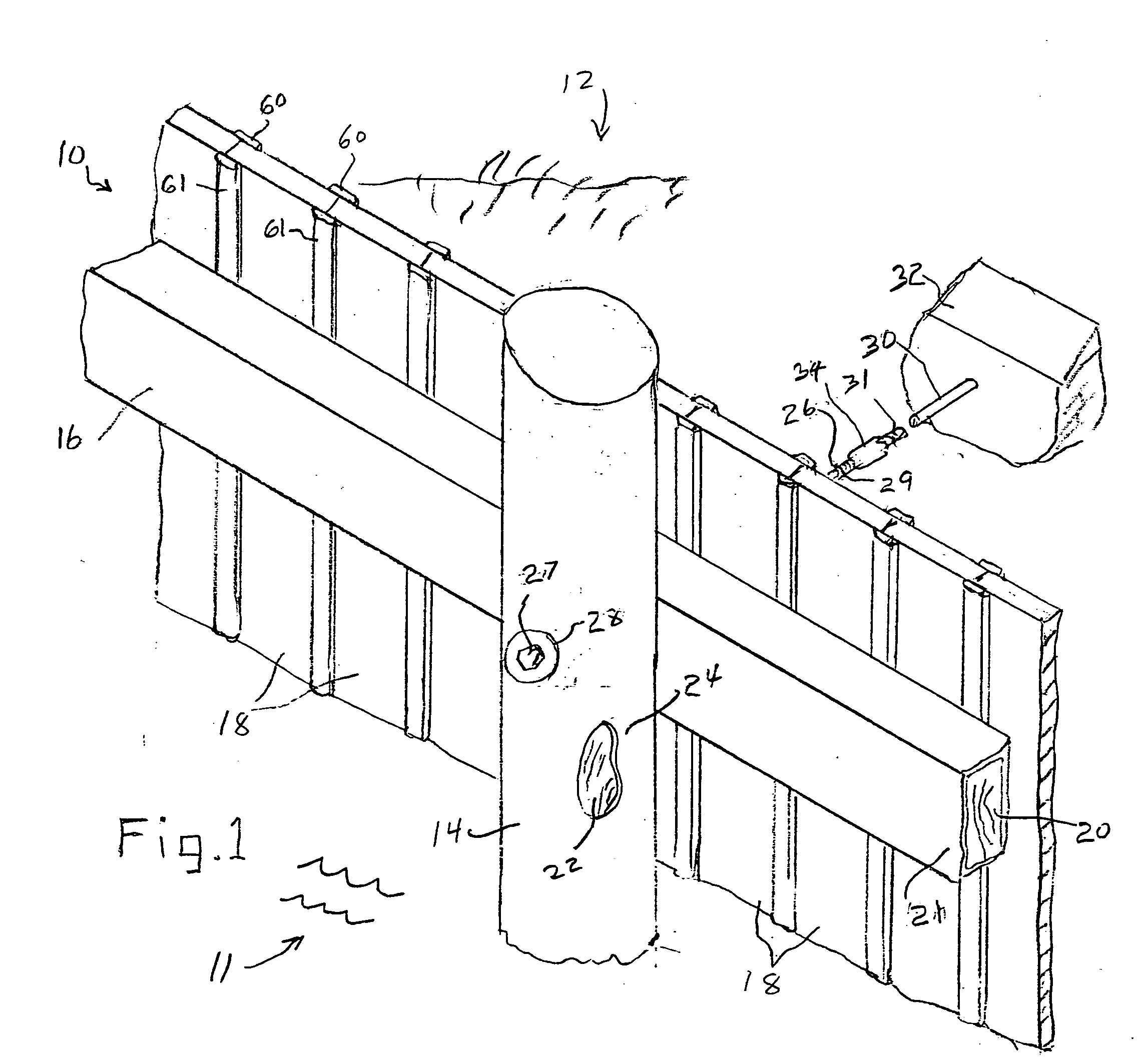

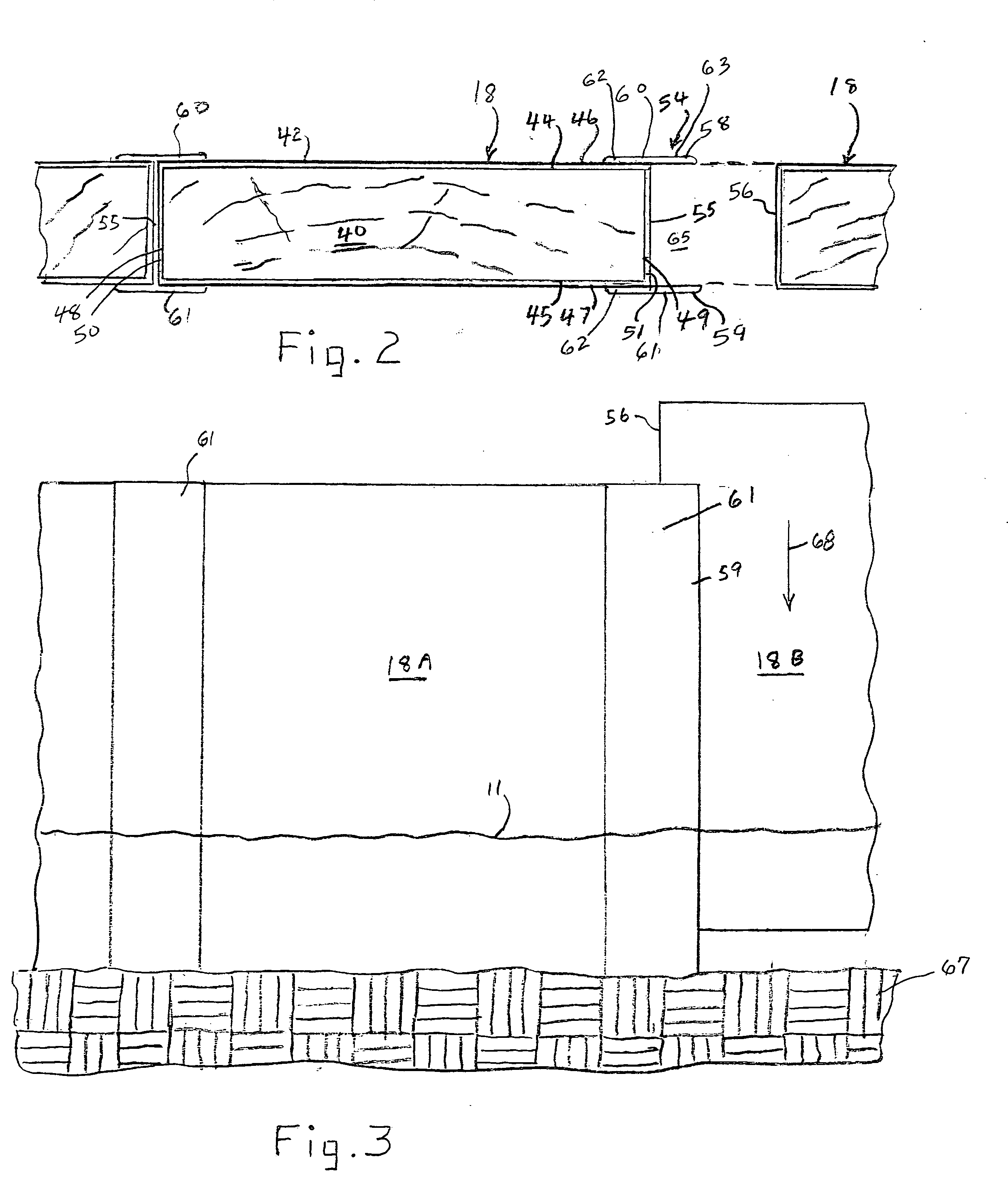

[0021] Referring now in more detail to the drawings, in which like numerals indicate like parts throughout the several views, FIG. 1 illustrates a retaining wall 10 that has been assembled for placement between a body of water 11 and a land mass 12, for separating the water from the land. While only a portion of the retaining wall is illustrated, it will be seen that it includes a plurality of vertical piles 14, horizontally extending wales 16, and a plurality of elongated, vertically oriented structural panels 18 placed in edge-to-edge relationship. The piles 14 are oriented vertically so that they can be driven downwardly through the water 11 and into the earth below so that the lower end portions of the piles are embedded in the earth and remain stabilized by the earth. Wales 16 are arranged in end-to-end relationship and extend horizontally between the piles 14 and the land mass 12. The structural panels are elongated and extend vertically. The structural panels are driven downw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com