Single piece vane knob

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

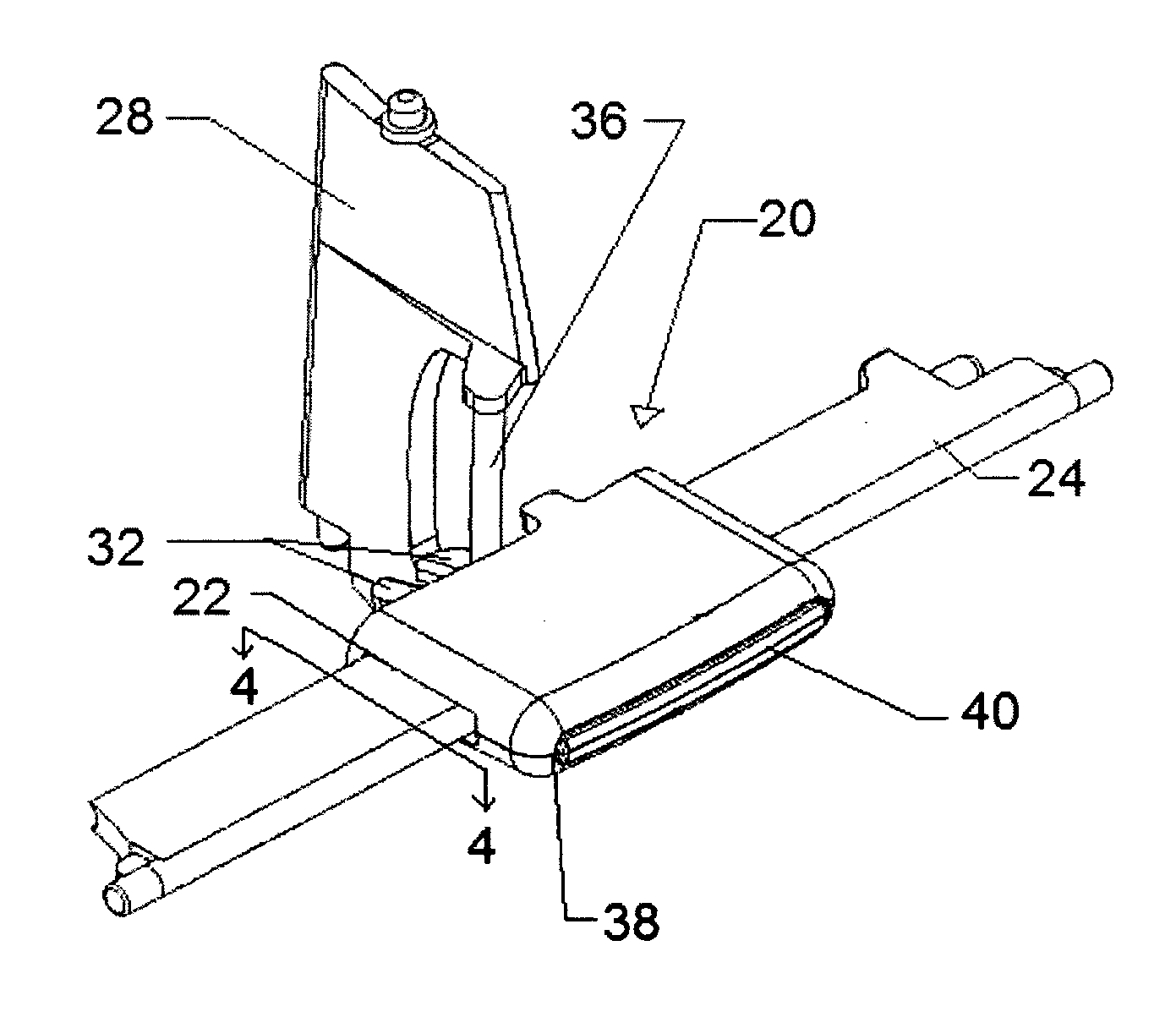

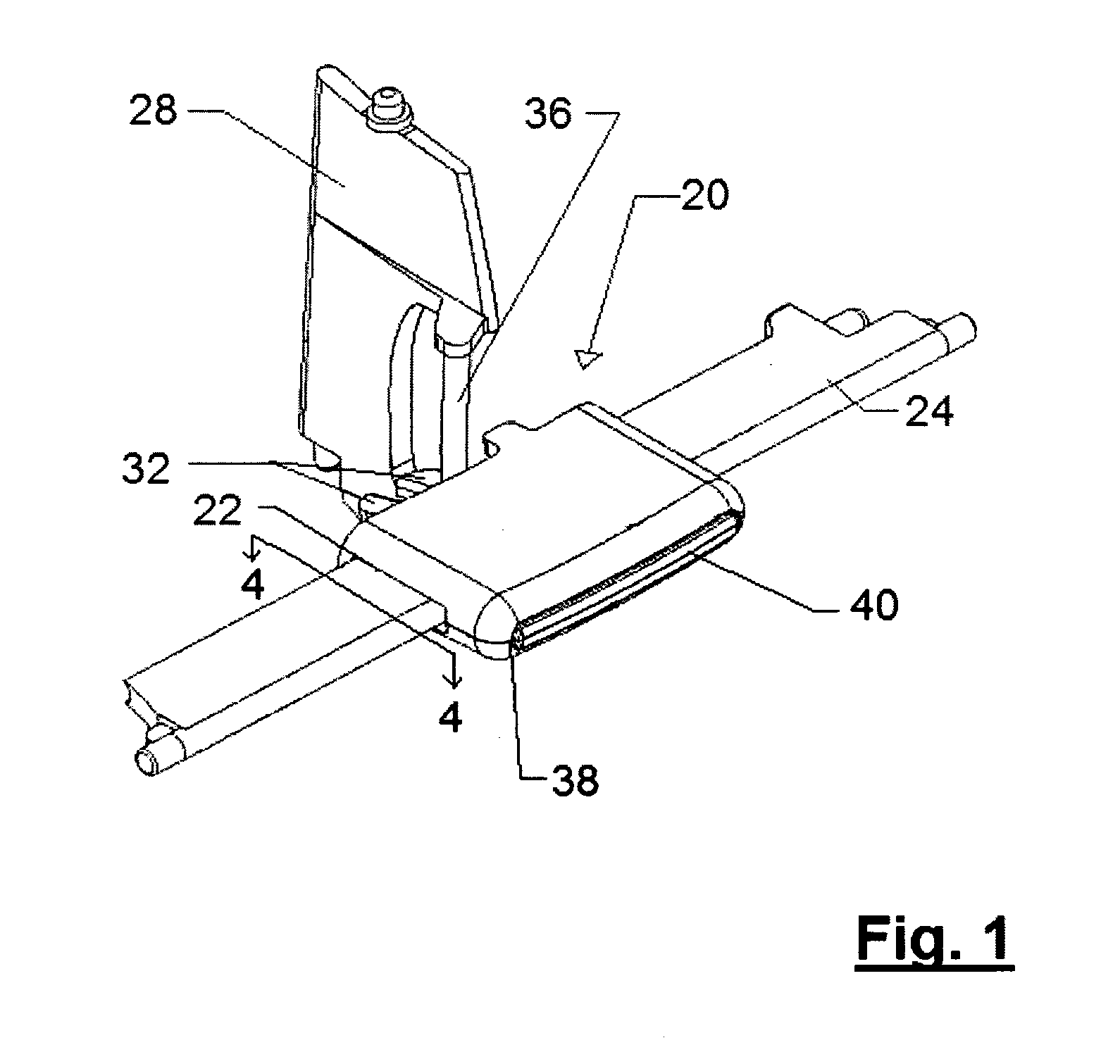

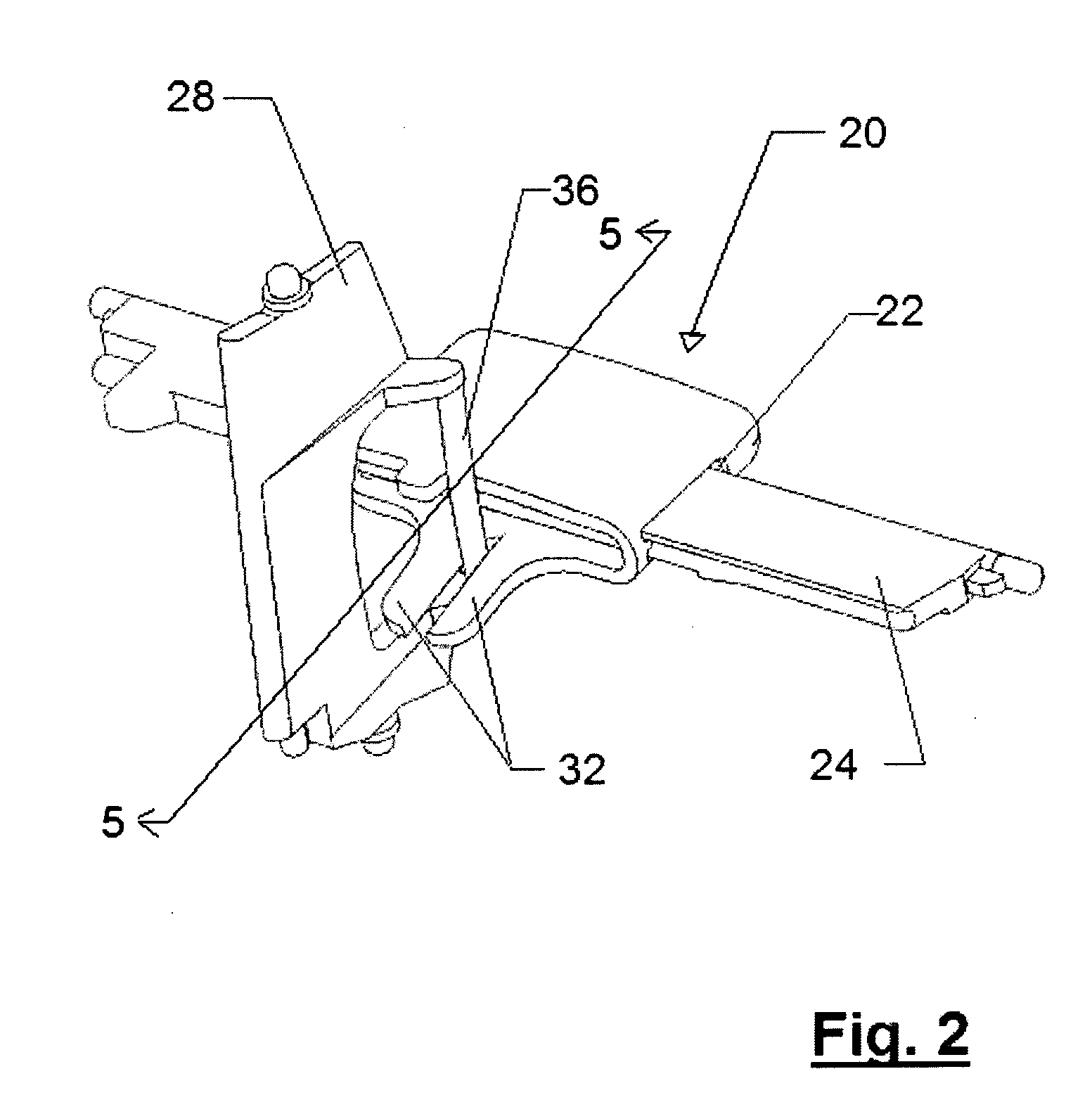

[0020] A vent control knob with an integral resilient member in accordance with the present invention is indicated generally at 20 in FIGS. 1, 2 and 3. As illustrated, control knob 20 has an enclosed passage 22 through which louver 24 passes and is thus a closed control knob. A vane 28 is connected to control knob 20 via a pair of fingers 32 extending rearwardly from knob 20 and engaging a rod 36 connected to vane 28. Control knob 20 includes an aperture 38 extending therethrough and the front of which can be closed with a trim or accent piece, such as chromed insert 40, for aesthetic reasons. Aperture 38 permits a resilient member, discussed below, to be integrally molded within knob 20. Control knob 20 can be slid along louver 24 to move rod 36, and thus turn vane 28, and the other vanes (not shown), as desired.

[0021] As best seen in FIGS. 4 and 5, passage 22, through control knob 20, includes an integrally formed resilient member, in this embodiment spring 48, which acts between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com