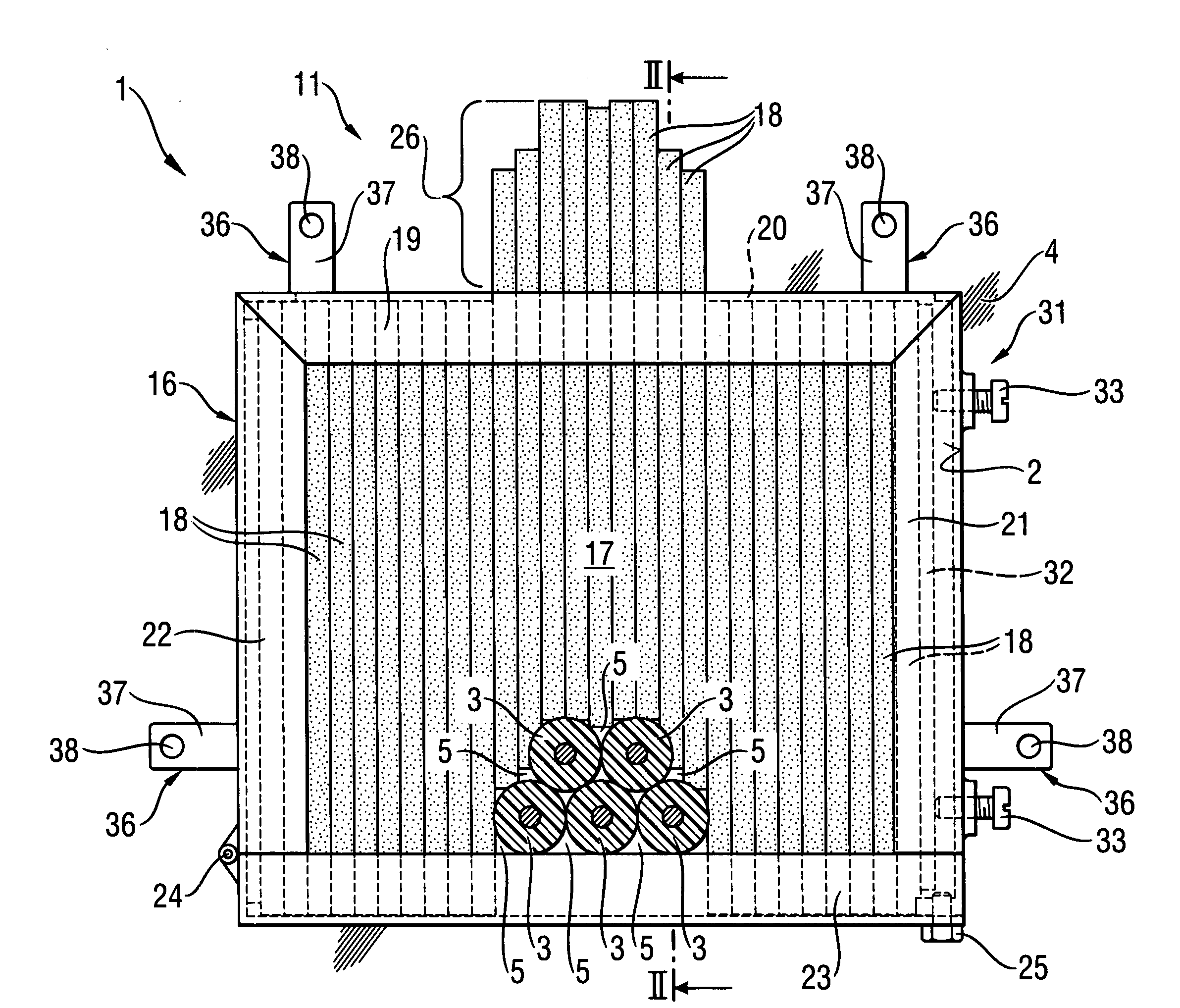

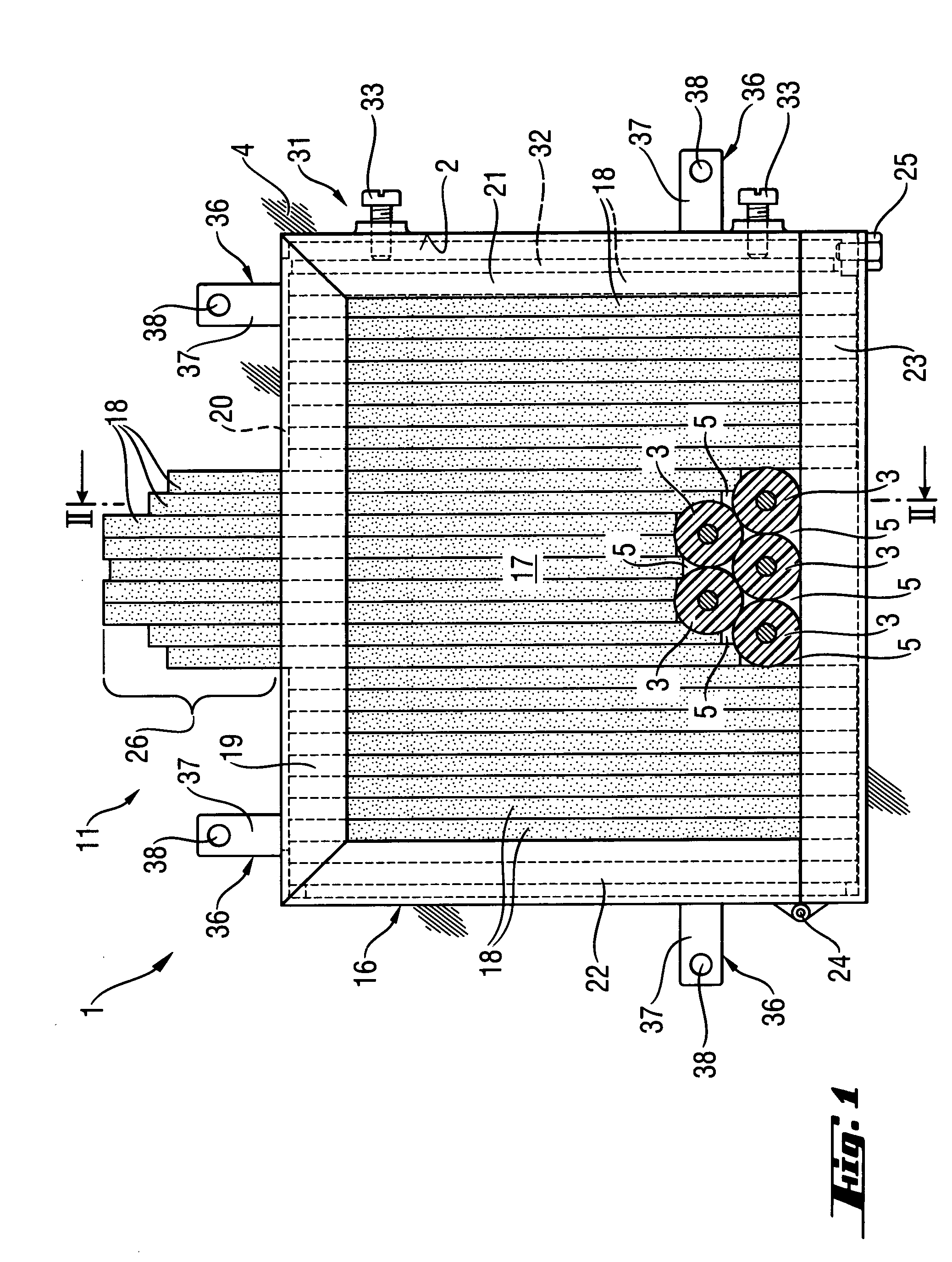

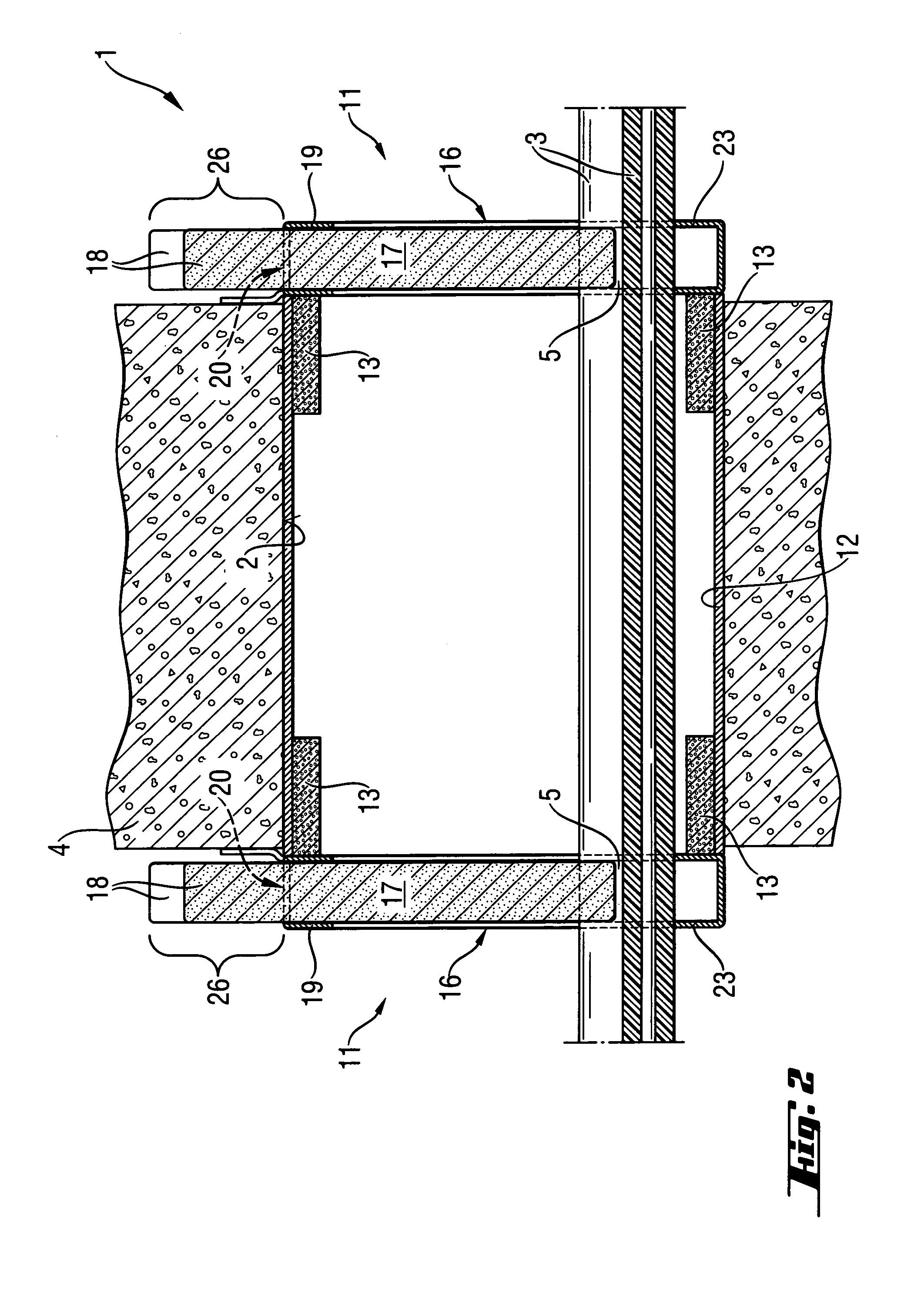

[0012] A plurality of strip-shaped sealing elements close the leadthrough space, which is enclosed by the frame member, in a fence-like manner. The strip-shaped sealing elements are tightly arranged next to each other, forming a substantially closed wall. Advantageously, all of the strip-shaped sealing elements are arranged parallel to each other. In addition, to a flue gasproofness, the inventive device also insures damping of an airborne

noise. The strip-shaped sealing elements are formed, advantageously, of a close-

cellular material, e.g., of a close-cellular foam material, are arranged tightly next to each other, and can be easily displaced relative to each other.

[0013] As a result of such arrangement, the strip-shaped sealing elements can be easily conformed to the profile of the pass-through conduits. Through the opening in at least one frame section of the frame member, each separate strip-shaped sealing element can be withdrawn from the leadthrough space in accordance with the profile or contour of the conduits passing through a corresponding region.

[0014] Advantageously, the at least one opening is formed as a through-slot, with the frame section provided with the through-slot, forming a top section of the frame member in the mounted condition of the device. The sections of the strip-shaped sealing elements, which project from the leadthrough space through the through-slot, can be pulled down for closing gaps and openings beneath the conduits and between the adjacent conduits. Thus, no additional fireproof materials, such as sealing masses or moduls, become necessary for a perfect closing of a leadthrough in a constructional element. The tight arrangement of the strip-shaped sealing elements next to each other insures a flue gasproofness and a cold flue gasproofness achievable with the inventive device.

[0016] Advantageously, there is provided on the frame member at least one locking device for securing the strip-shaped sealing elements which are positioned relative to each other. In order to remove conduits from the leadthrough or insert additional conduits into the leadthrough which is closed with the device in which the strip-shaped sealing elements are fixed, firstly, the locking device is released, an appropriate

adaptation is made and, after aligning of the strip-shaped sealing elements anew, the locking device is tightened, fixing the strip-shaped sealing elements. The locking device acts on the strip-shaped sealing elements preferably sidewise, i.e., transverse to the longitudinal extent of the strip-shaped sealing elements. Upon tightening of the locking device, the gaps between the strip-shaped sealing elements are closed, which substantially improve the flue gasproofness of the formed sealing. When the strip-shaped sealing elements are made from a

compressible material, a particularly tight closing of the leadthrough is achieved when the locking device is tightened. The locking device includes a pressure place, which is provided in the frame member, and screws which act on the pressure place, pressing it against the strip-shaped sealing element. According to an alternative embodiment of the locking device, it is formed as a clamping device having clamping cheeks that act on the strip-shaped sealing elements, aligning and fixing them.

[0019] Advantageously, a frame section of the frame member, which is located opposite the section with an opening, is removably secured on the frame member. This enables an easy

insertion of further conduits into the device even when the device is secured to the constructional element. After removing the removable frame section, the strip-shaped sealing elements can be pulled out of the leadthrough space enclosed by the frame member, so that additional conduits can be passed through the leadthrough. The removable frame section of the frame member can, e.g., be attached to the frame member with screws or a holding device. According to one embodiment of the device, the removable section if pivotally secured on the frame member so that after the release of the holding device or means, the removable section is pivoted away, without being detached, which insure that it would not be lost.

[0021] According to an embodiment of the invention, a box-shaped section can be provided on the frame member which, e.g., enables arrangement of the frame member at a distance from an outer wall of a constructional element. Thus, e.g., later, an

insulation layer can be placed at the edge of the leadthrough. In addition, a one-sided arrangement of the inventive device on a to-be-closed leadthrough, adequately insures the flue gasproofness. With the additional box-shaped section, the inventive device can be provided already during formation of a constructional element, e.g., during

casting of a boarding. When the arrangement of an

intumescent fireproof band or inlay is contemplated, it is advantageously provided in the box-shaped section.

Login to View More

Login to View More  Login to View More

Login to View More