Piezoelectric actuator and pump using same

a technology of ferroelectric actuators and miniature diaphragm pumps, which is applied in the direction of positive displacement liquid engines, pumping machines, machines/engines, etc., can solve the problems of inapposite prior art and no prior art showing a flex valve with a miniature pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

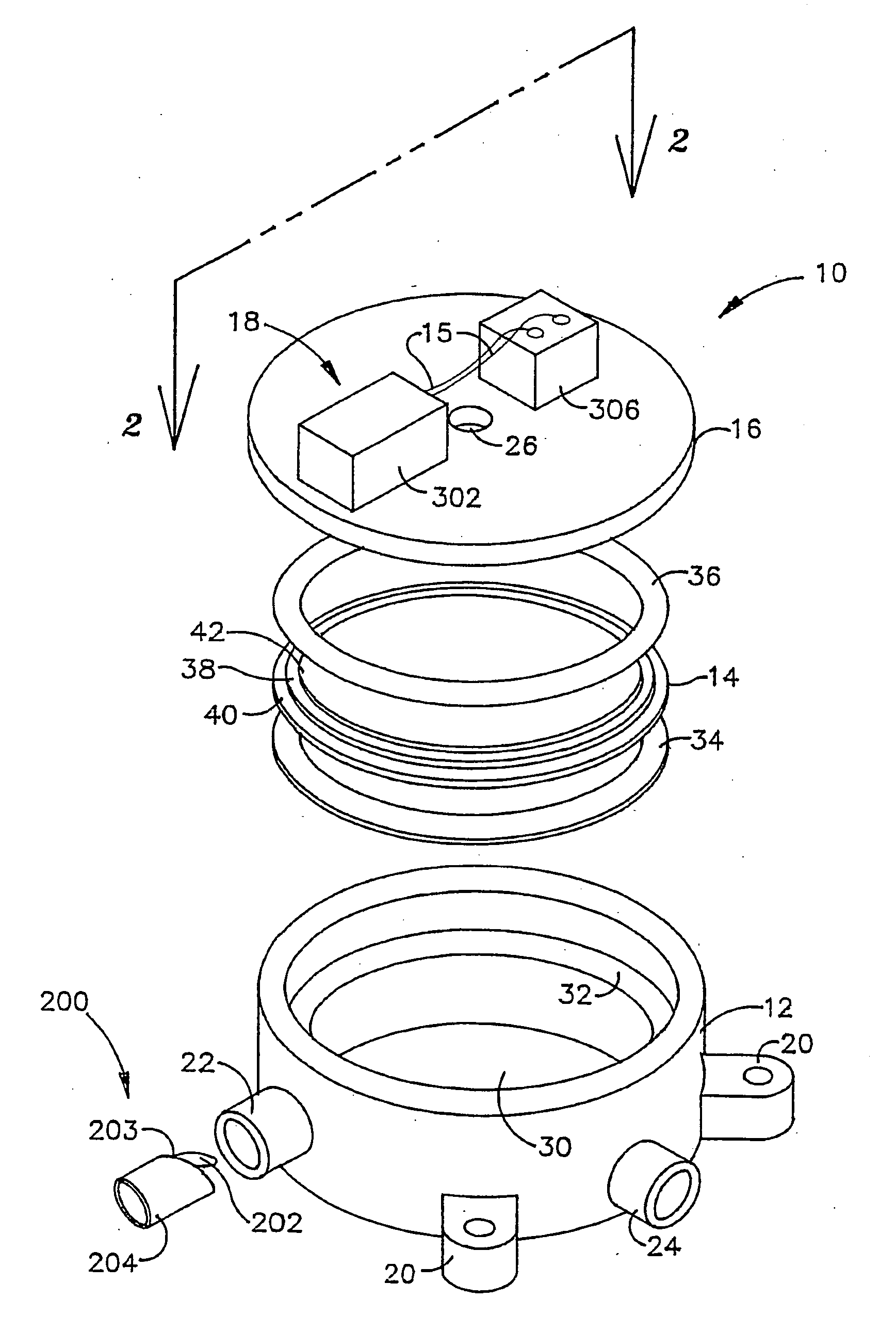

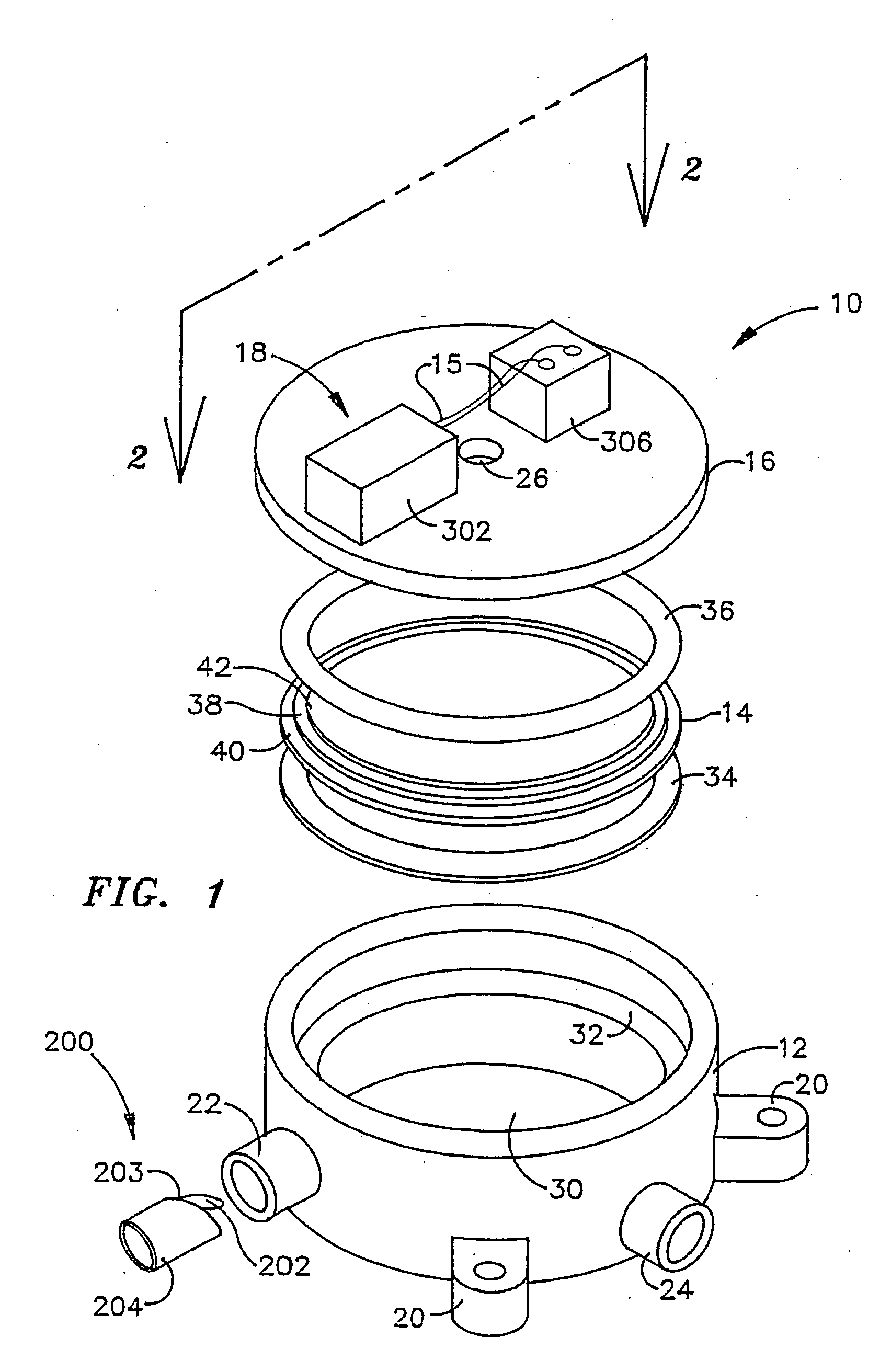

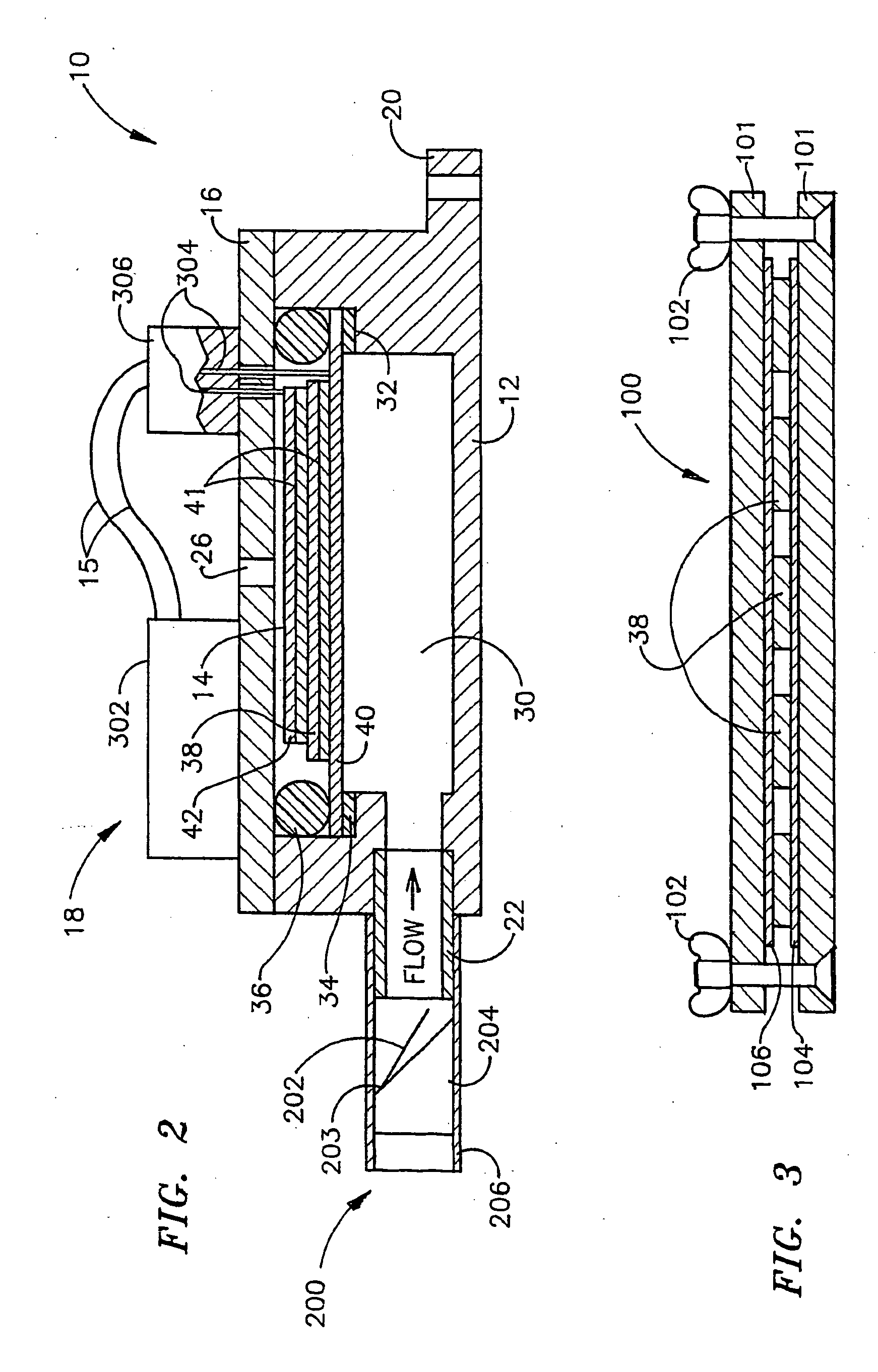

[0017]FIG. 1 shows how the piezoelectric actuator of the present invention may be used in a miniature diaphragm pump. The pump 10 is generally in the form of a circular short cylinder. It includes the pump body 12, piezoelectric actuator 14, pump cover 16 and piezoelectric actuator electronic driver circuit 18. The pump body 12 has lugs 20 for mounting the pump to any substrate. Inlet 22 and outlet 24 are part of the pump body 12 though they could be separate pieces otherwise fastened to the pump body. The pump cover 16 is essentially the same diameter and of the same material as the pump body 12. The material would ordinarily be of a standard plastic such as acetal[DELRIN®], PVC, or PC, or of a metal such as stainless steel or brass. These are preferable since they can be easily machined or thermally formed. The cover 16 may be fastened to the pump body 12 by any means such as by a fast-curing adhesive while the pump body 12 and cover 16 are under compression such as by clamping. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Force | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com