Assembled block

a technology of assembled blocks and blocks, applied in the field of three-dimensional blocks, can solve the problems of increasing manufacturing costs, severely restricting the final shape of assembled blocks,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

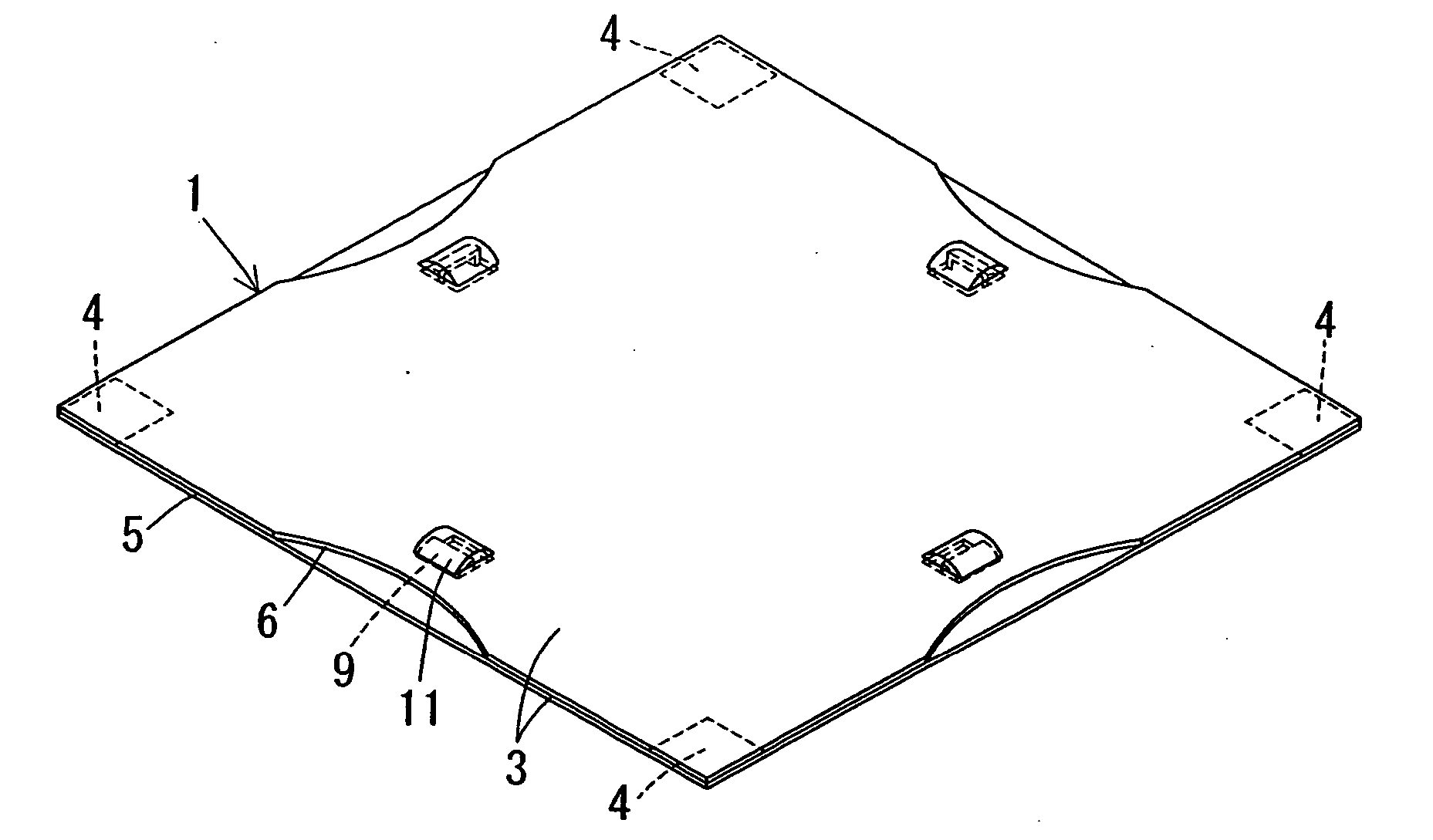

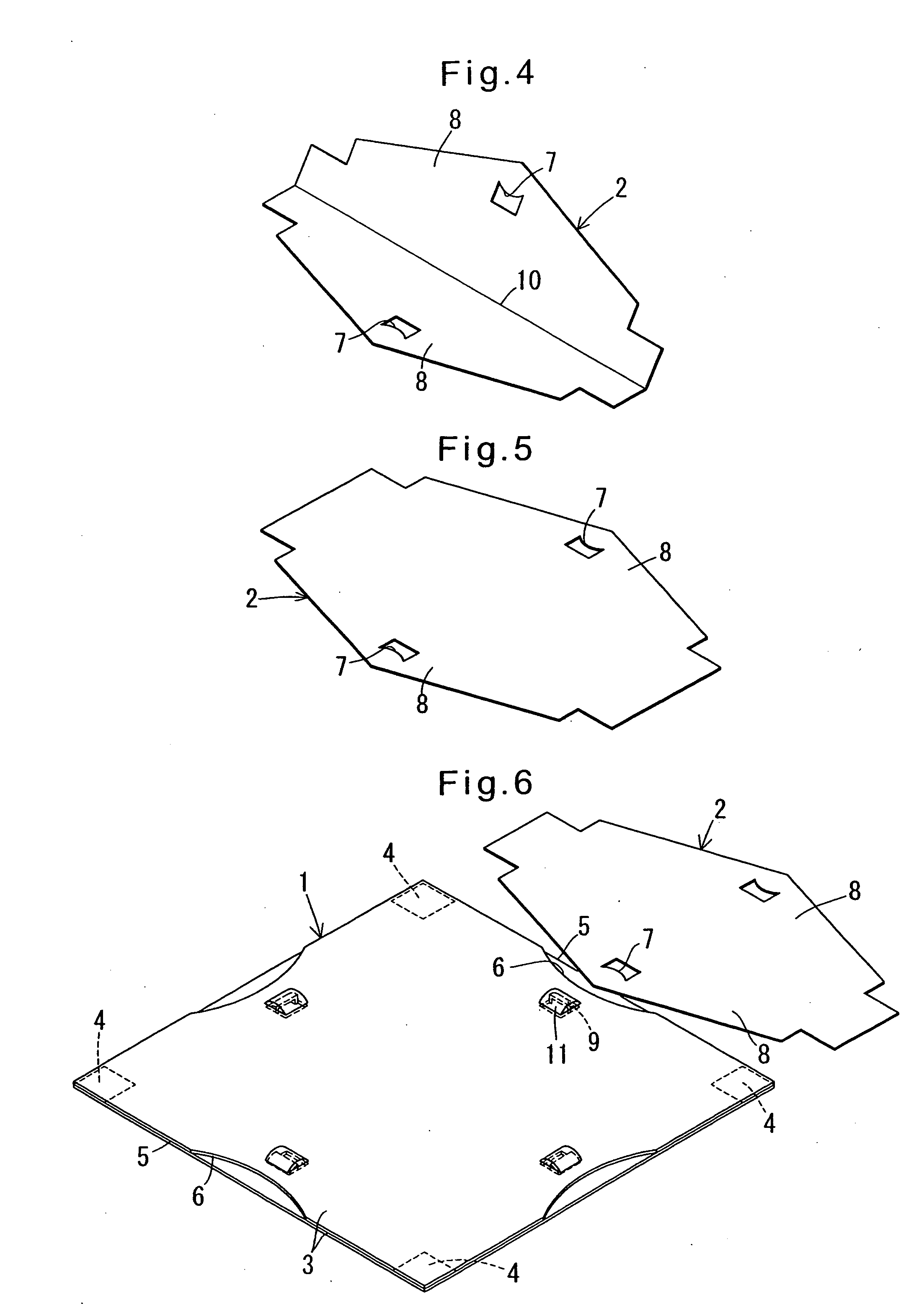

[0051] First, FIGS. 1 to 24 show the embodiment comprising plastic plates.

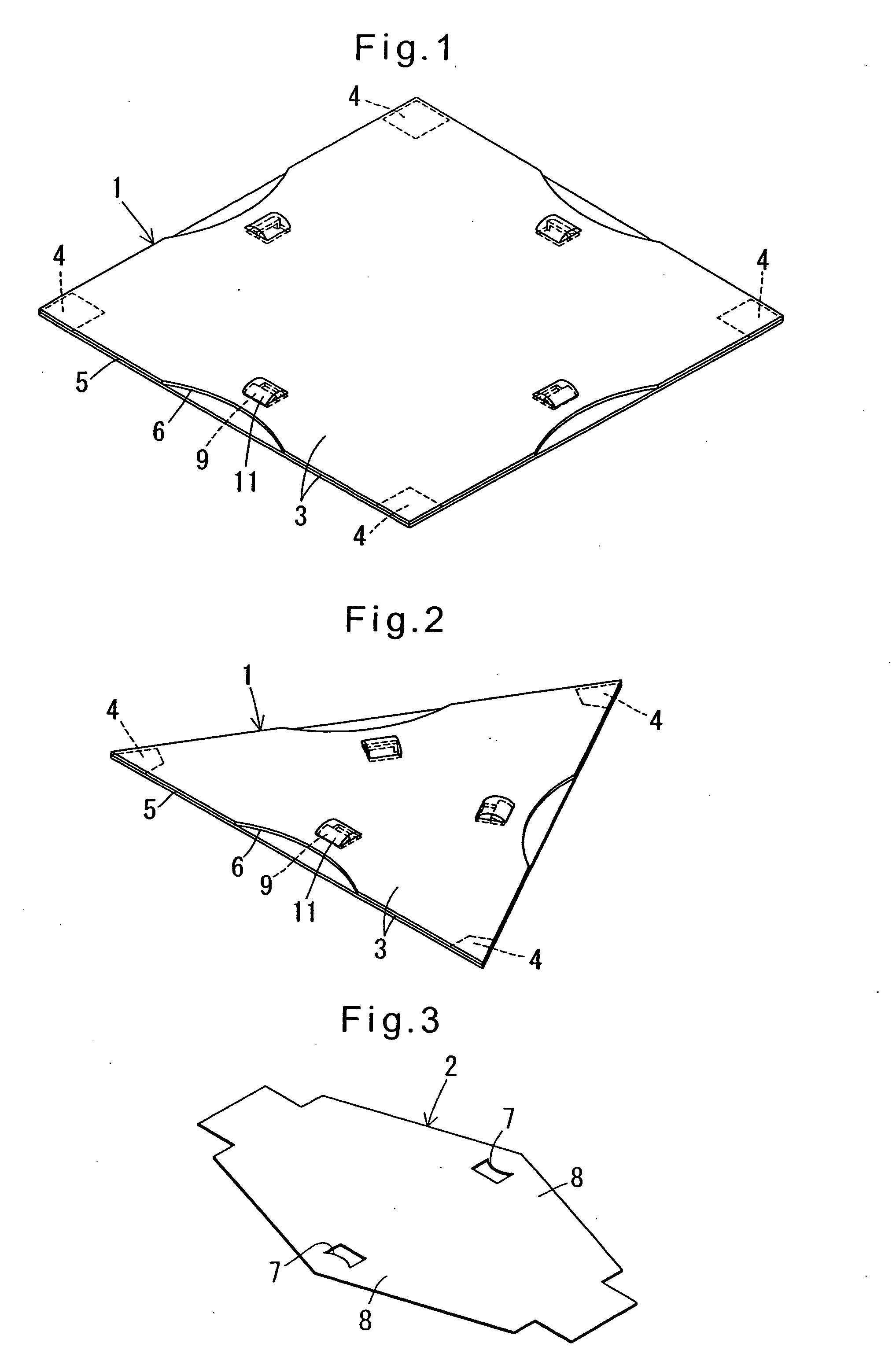

[0052] The assembled block of this embodiment comprises block plates 1 as shown in FIGS. 1 and 2, and joints 2 as shown in FIGS. 3 to 5. The block plates 1 comprise square ones as shown in FIG. 1 and equilateral triangular ones as shown in FIG. 2. All the block plates 1 have edges of equal length and are equal in thickness too.

[0053] The block plates 1 shown in FIGS. 1 and 2 are formed by laminating two flexible plastic base plates 3 (upper and lower plates 3). The two base plates 3 are joined together by e.g. fusing them at joint portions 4 at the corners.

[0054] Except the joint portions 4, the edges of the base plates 3 are not joined together, thus defining receptacles 5 through which a joint 2 can be inserted into between the base plates 3. Each edge of the upper base plate 3 is cut out at its central portion to form an arcuately concave guide pocket 6.

[0055] Slightly inwardly of each edge of the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com