Plating apparatus and plating method

a technology of plating apparatus and plating film, which is applied in the direction of electrolysis components, manufacturing tools, and semiconductor/solid-state device details, etc., can solve the problems of imposing a limitation on affecting the quality of the plating, and small footprint, so as to enhance the in-plane uniformity of the plated film thickness, good gas-bubble releasability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] Preferred embodiments of the present invention will now be described with reference to the drawings. The following description illustrates the case of using a substrate, such as a semiconductor wafer, as an object to be plated.

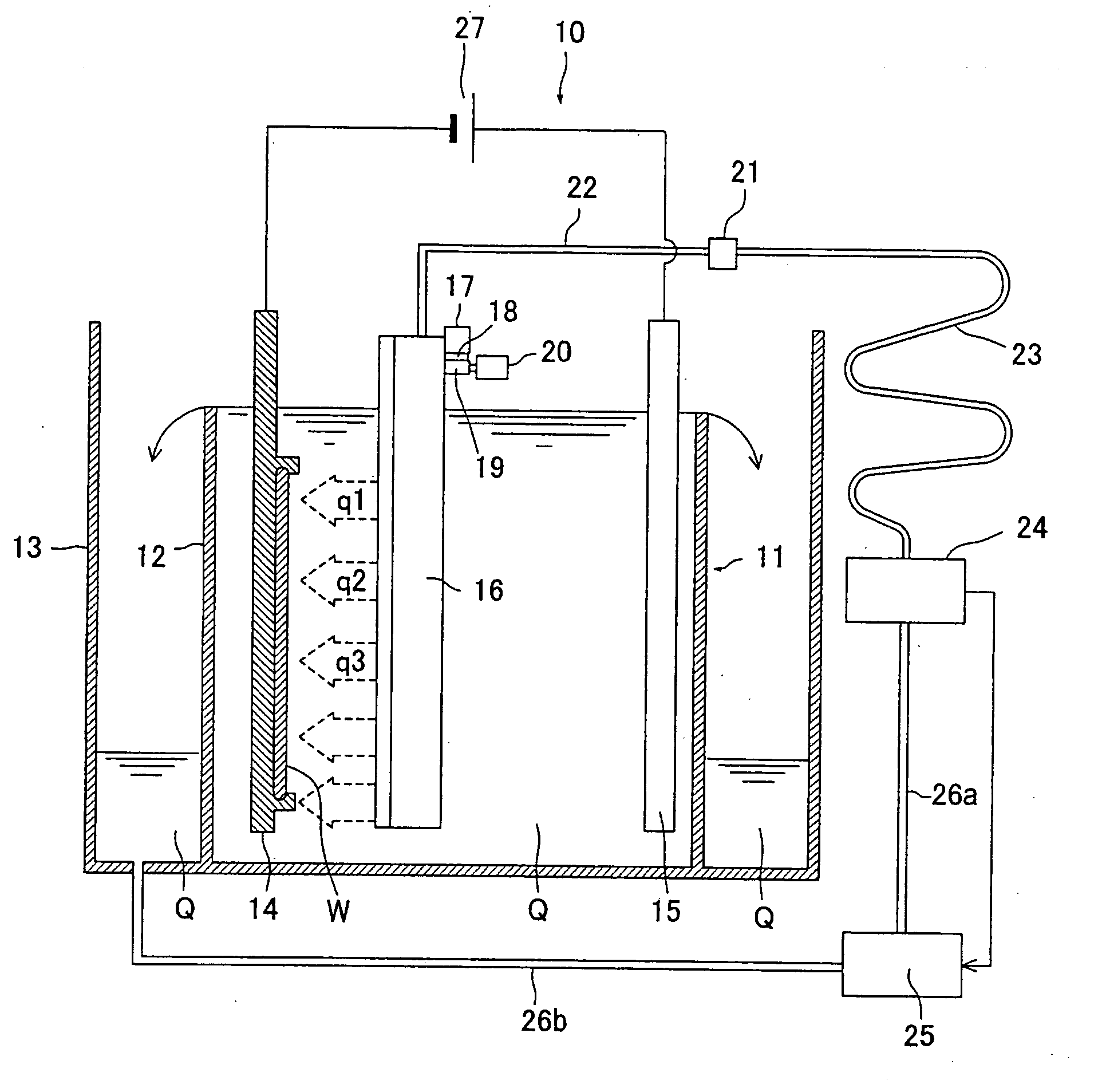

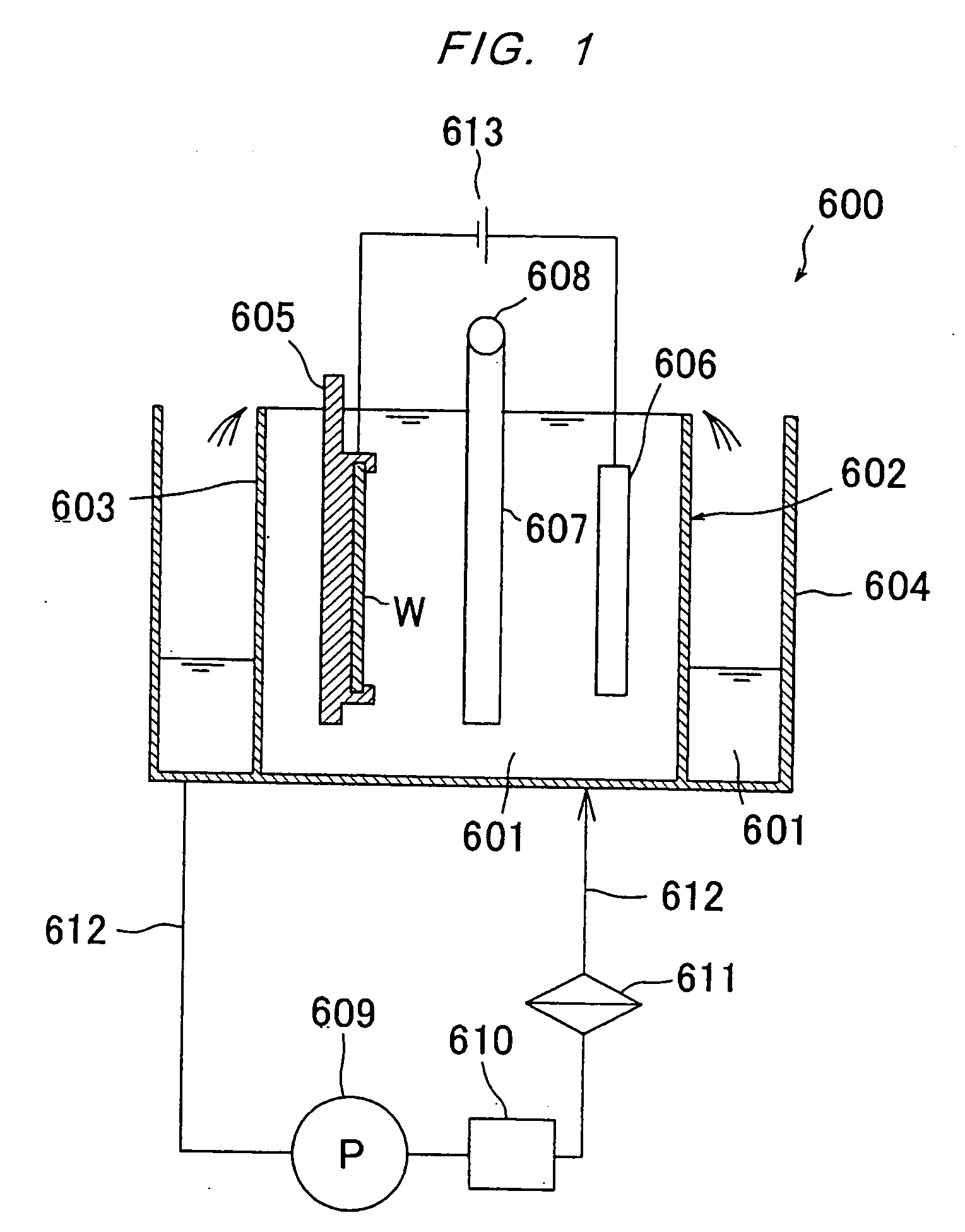

[0090]FIG. 6 is a schematic vertical sectional view of a plating apparatus according to an embodiment of the present invention, and FIG. 7 is a plan view showing the arrangement of a substrate holder, an anode and plating solution jet nozzles in a plating tank. The plating apparatus 10 is an electroplating apparatus, and includes a plating tank 11 for holding therein a plating solution Q, and an overflow tank 13 for holding the plating solution Q that has overflowed the upper end of the overflow weir 12 of the plating tank 11. In the plating tank 11, a substrate W, which is held by a substrate holder 14, and an anode 15, both immersed in the plating solution Q, are disposed vertically and opposite to each other at a predetermined distance. Plating solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com