Axle straightening press

a technology of axle and axle, which is applied in the direction of manufacturing tools, metal-working apparatus, and shaping tools, etc., can solve the problems of not having alignment dowels, and not having hammer blowing, etc., to achieve low manufacturing cost, easy and efficient manufacturing and marketing, and low price of sale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

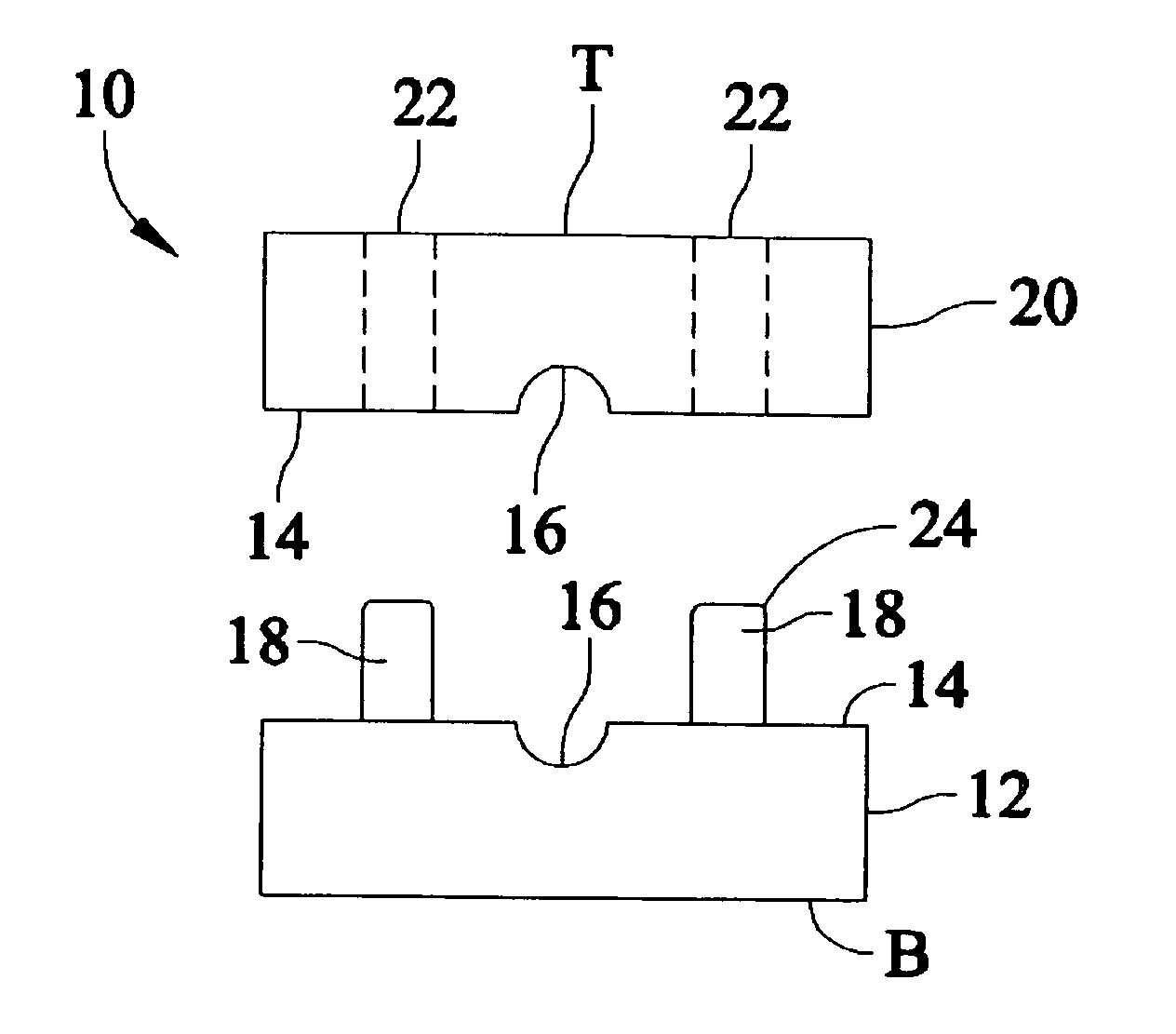

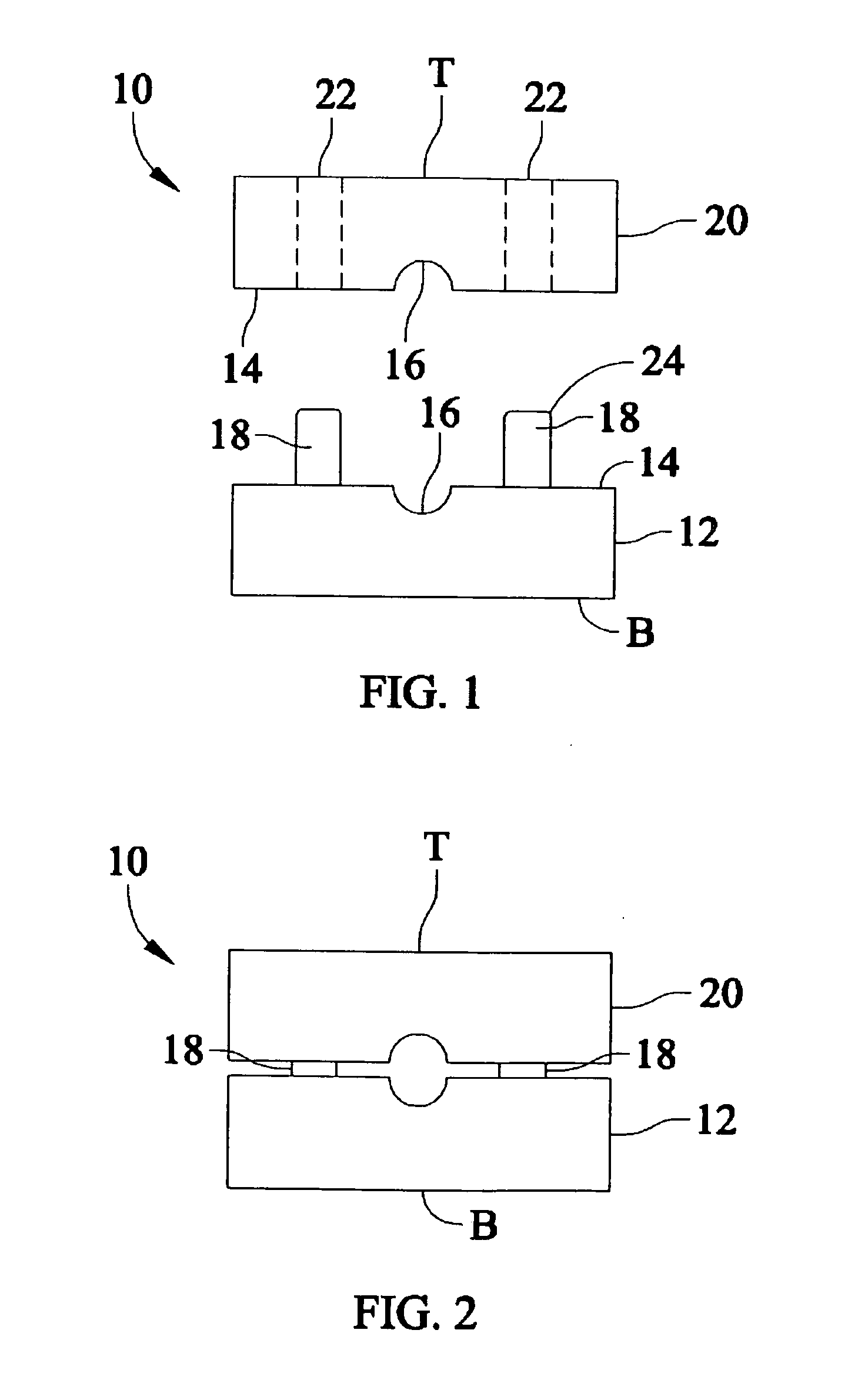

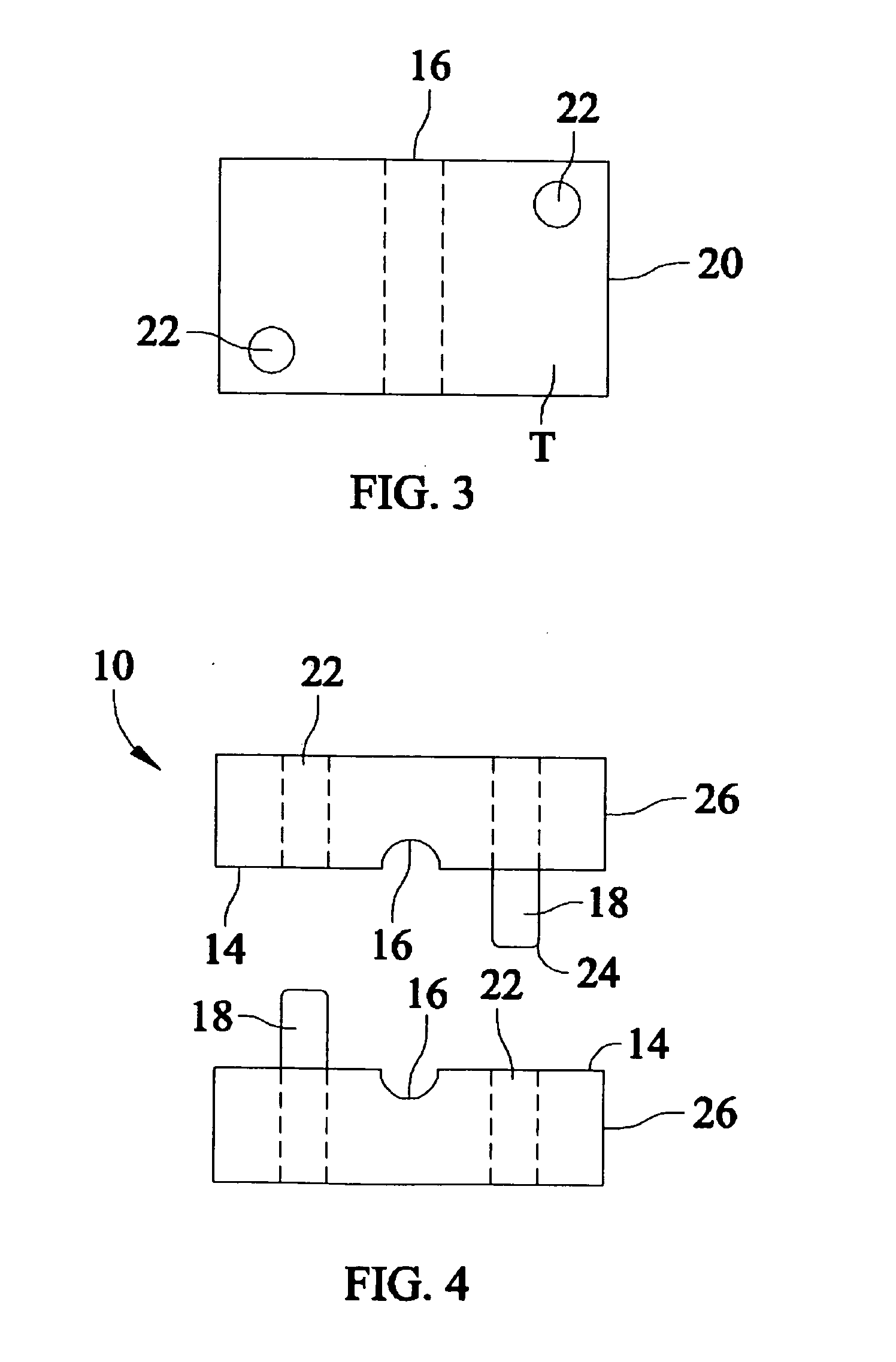

[0042] Referring now to the drawings, and particularly to FIGS. 1-5, a preferred embodiment of the axle straightening press of the present invention is shown and generally designated by the reference numeral 10. The present art overcomes the prior art limitations in straightening an axle by a Cub Scout with a hammer at minimal risk of injury. In FIG. 1, a new and improved axle straightening press 10 of the present invention for straightening axles is illustrated and will be described. More particularly, the axle straightening press 10 appears in a view with a female jaw 20 and a male jaw 12. The female jaw 20 has a top surface T generally rectangular in shape with an opposing mating surface 14. The mating surface 14 has a generally rectangular shape with a centered and transverse half channel 16 in the mating surface 14. The half channel 16 has a semi-circular cross section on a plane parallel to the longitudinal axis of the mating surface 14. The half channel 16 has its diameter co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com