Carrier for substrate film

a film carrier and substrate technology, applied in the field of substrate film carriers, can solve the problems of affecting the processing efficiency of substrate films, so as to enhance the rigidity of substrate films and enhance the rigidity of substrate units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

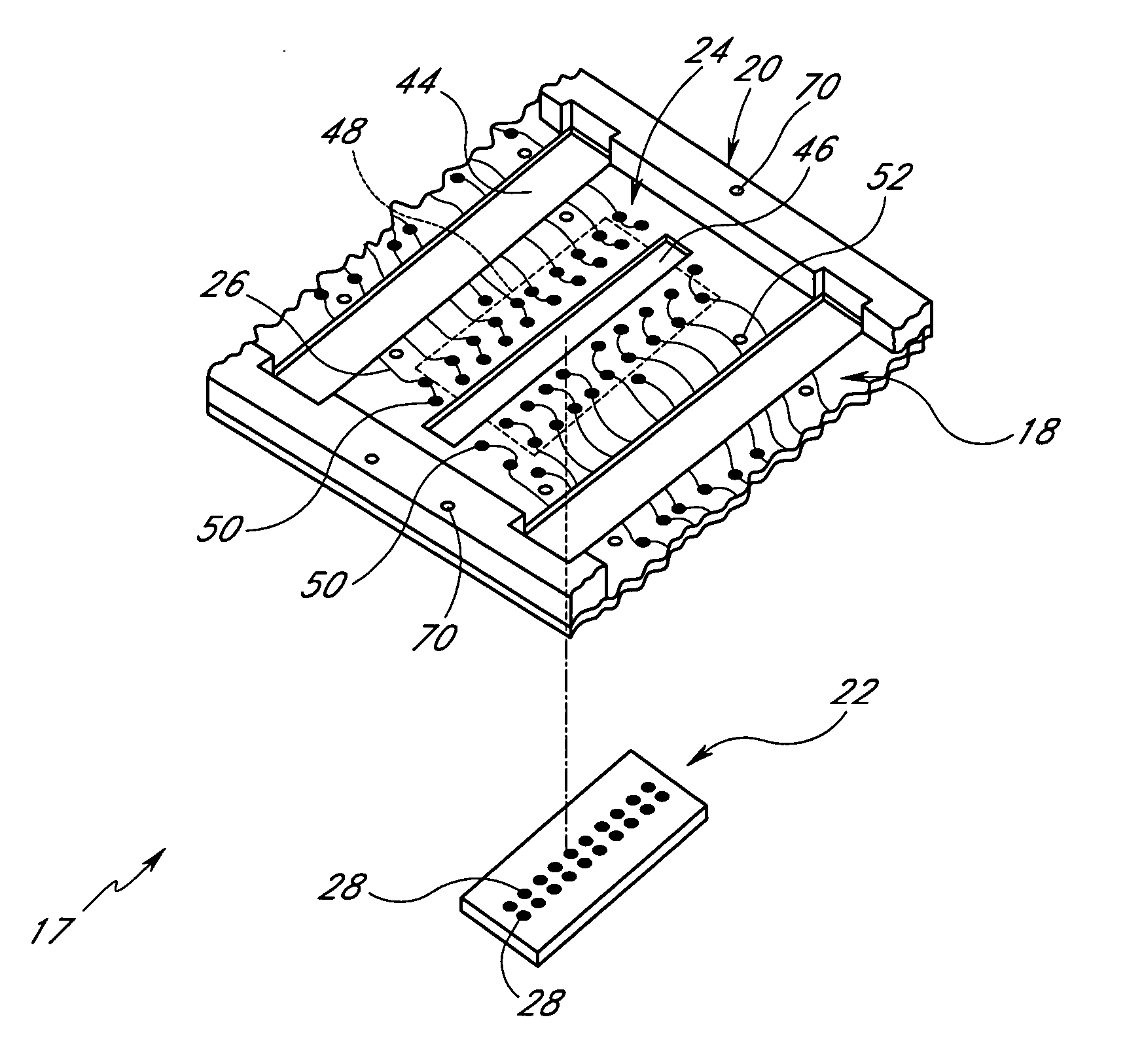

[0025]FIG. 1 schematically illustrates a ball grid array (BGA) chip package 10 and a printed circuit board (PCB) 12. The BGA package 10 serves as an encapsulating device for a die or chip and permits electrical access to the die via solder or electrode bumps 14. The PCB 12 includes a pattern of pads 16 which are arranged in alignment with the BGA solder bumps 14. This allows the BGA chip package 10 to be connected to the PCB 12. Of course, other chip packaging types may also be used, for example, pin grid arrays (PGA), dual in-line packages (DIP), and the like. These packaging types can be connected to compatible connectors on a PCB or other external circuitry.

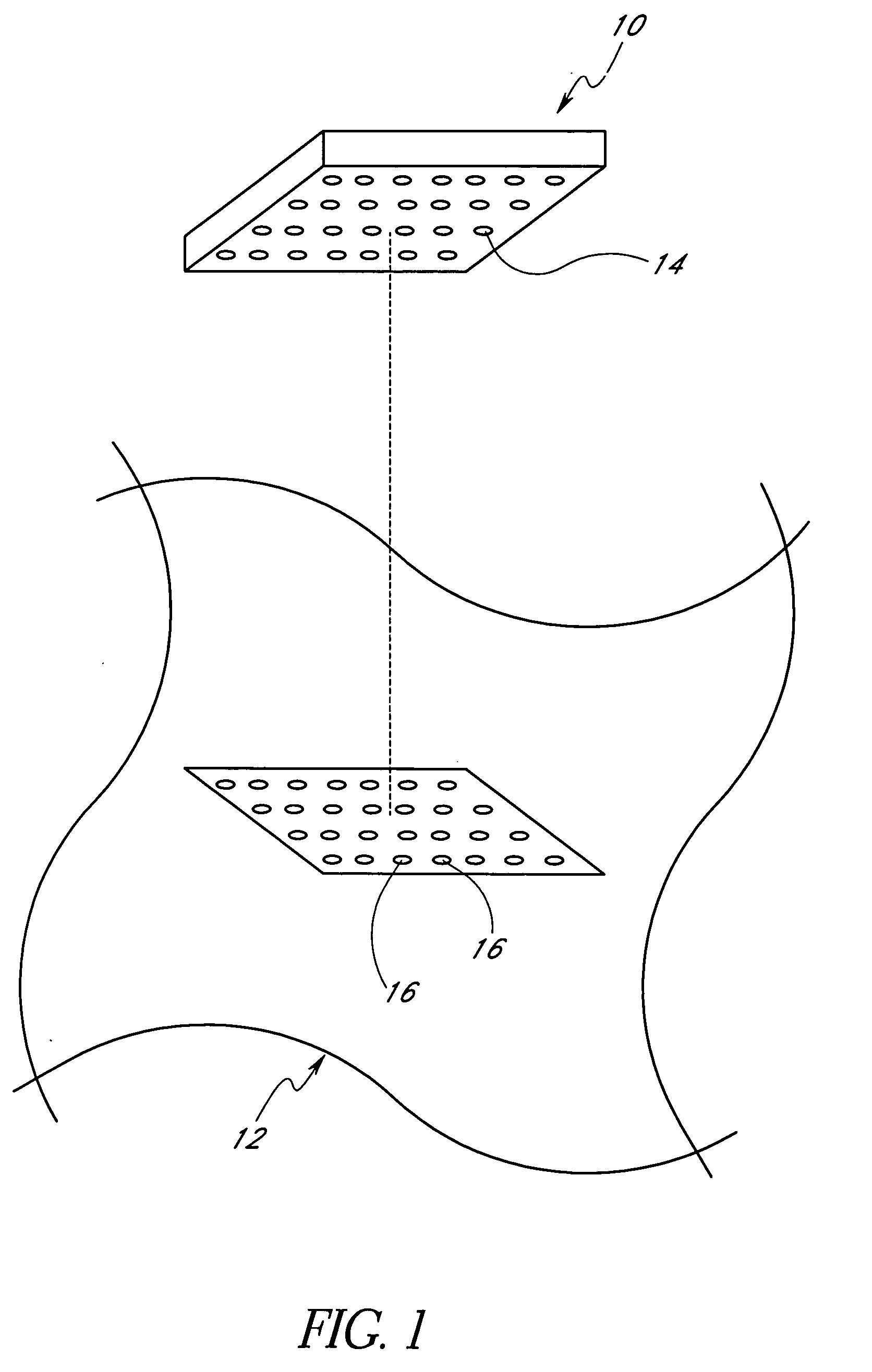

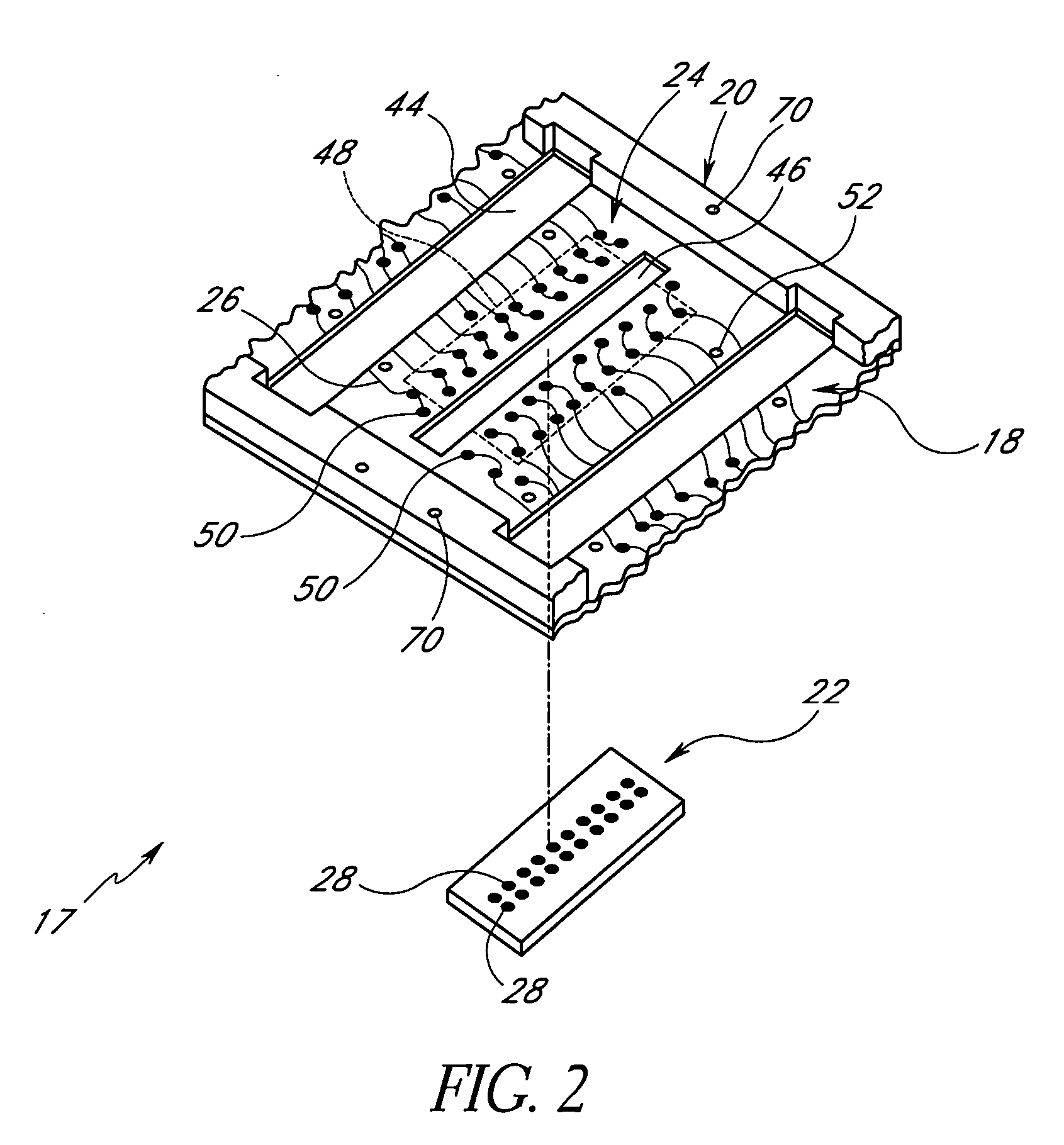

[0026] In accordance with one embodiment, FIG. 2 is a representation of a lead-over-chip (LOC) assembly 17 and generally shows a substrate film 18, a film carrier or structure 20 and a semiconductor die or chip 22. The substrate film 18 includes a plurality of substrate units 24, as discussed in greater detail below, with eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com