Two piece interlocking block system

a technology of interlocking blocks and blocks, applied in the direction of walls, constructions, building components, etc., can solve the problems of block walls being laid up, time-consuming and difficult systems, and keeping the cost of this type of construction high, so as to reduce the cost and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

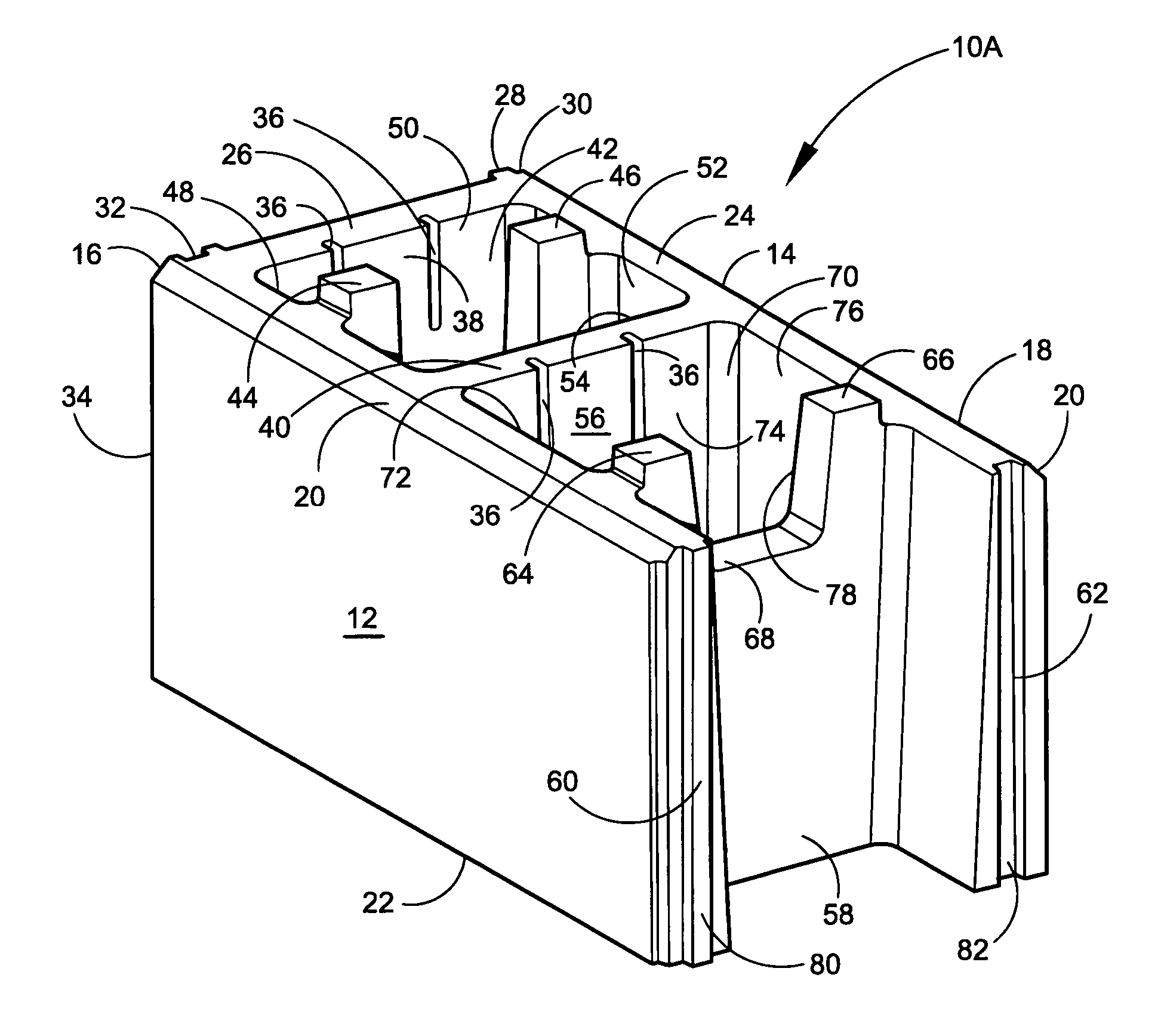

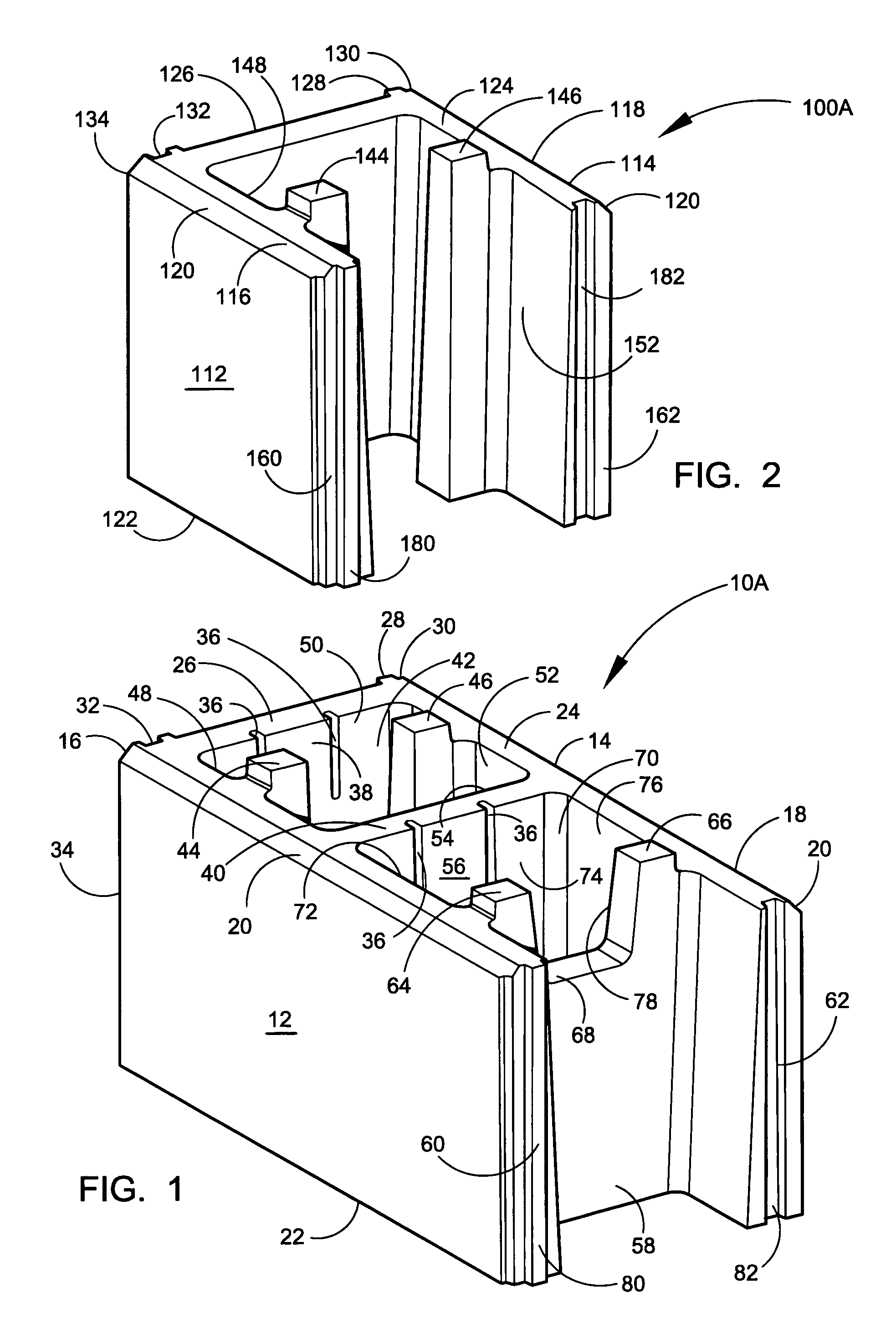

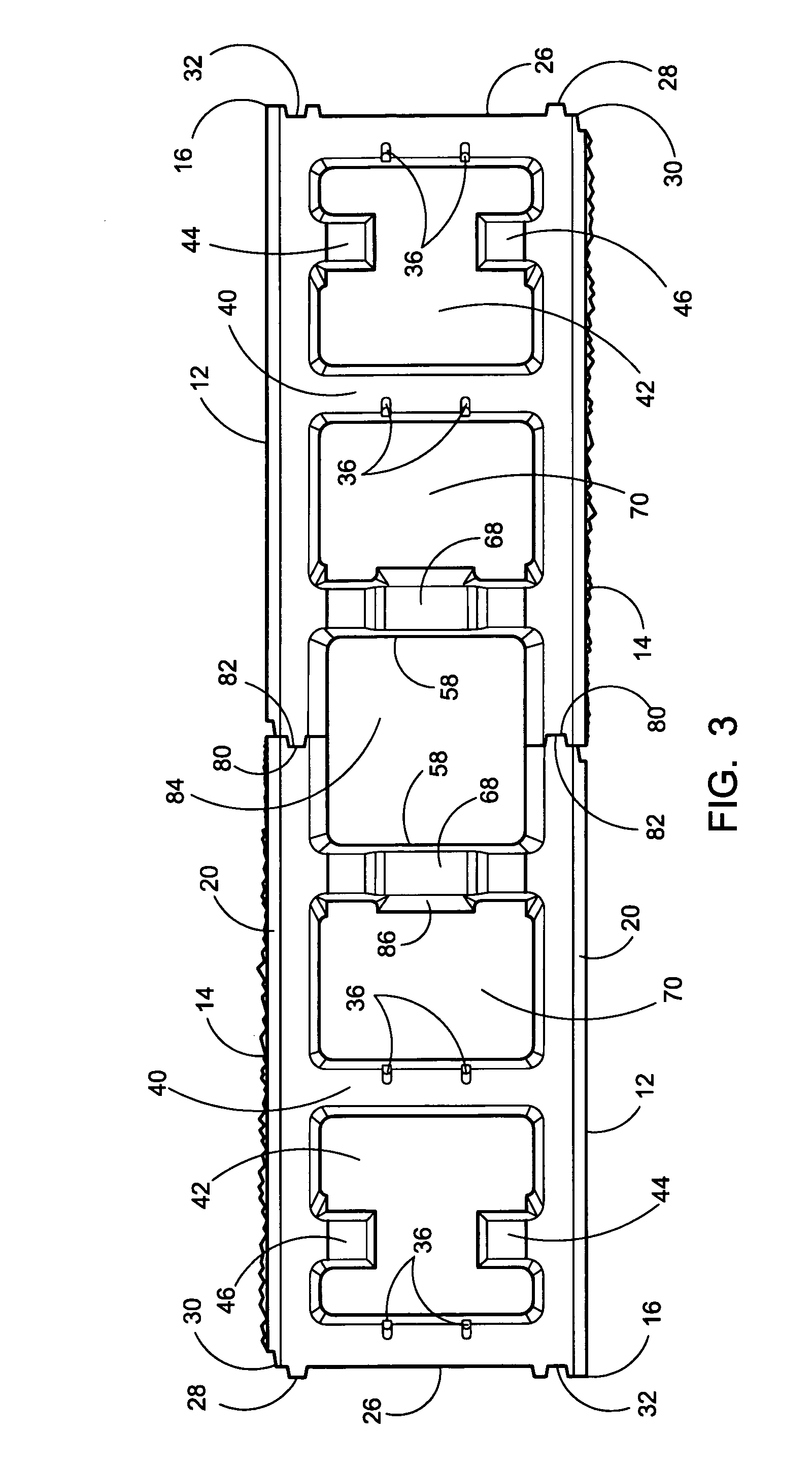

[0052] Referring now to the drawings, wherein similar parts of the invention are identified by like reference numerals, there is seen in FIG. 1 a perspective view of the Haener interlocking full block 10A with two parallel rectangular sides 12 and 14. This system requires that the blocks must be laid in the upright position and cannot be inverted although they can be rotated end to end. In the preferred embodiment of the invention, the top edges 16 and 18 have a beveled surface 20. The bottom surface 22 of the full interlocking block 10 is basically flat and parallel to the top surface 24. The flat end wall 26 has an engagement tongue 28 on one side edge 30 and a receiver groove 32 on the other side edge 34. A pair of knock out grooves 36 are located on the inner surface of the flat end wall 26. By hitting between the knockout grooves 36 with a hammer, an upper section 38 of the flat end wall 26 may be removed as a means to insert reinforcing bars. A center wall 40 extends between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com