Sheet metal tie

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

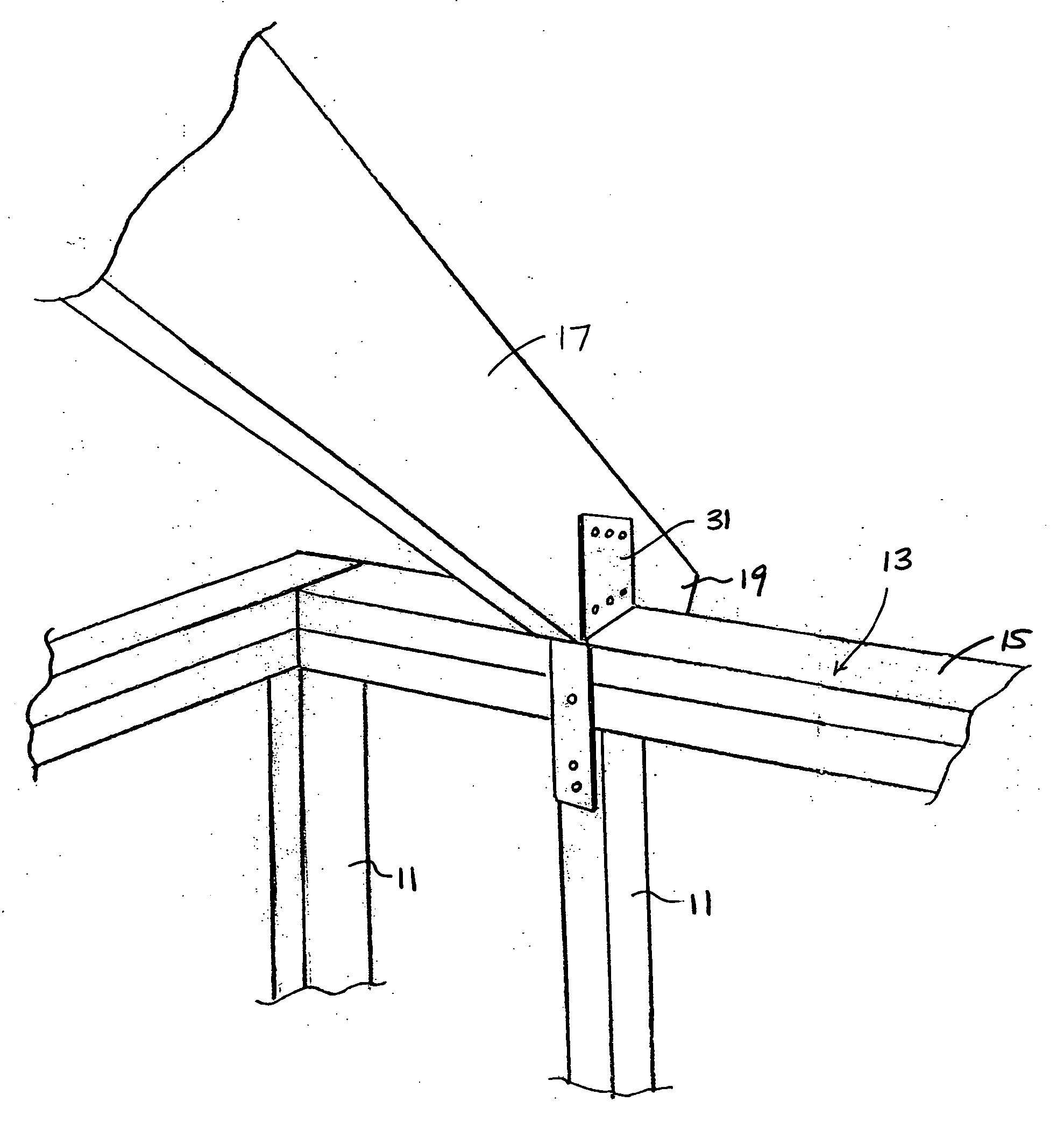

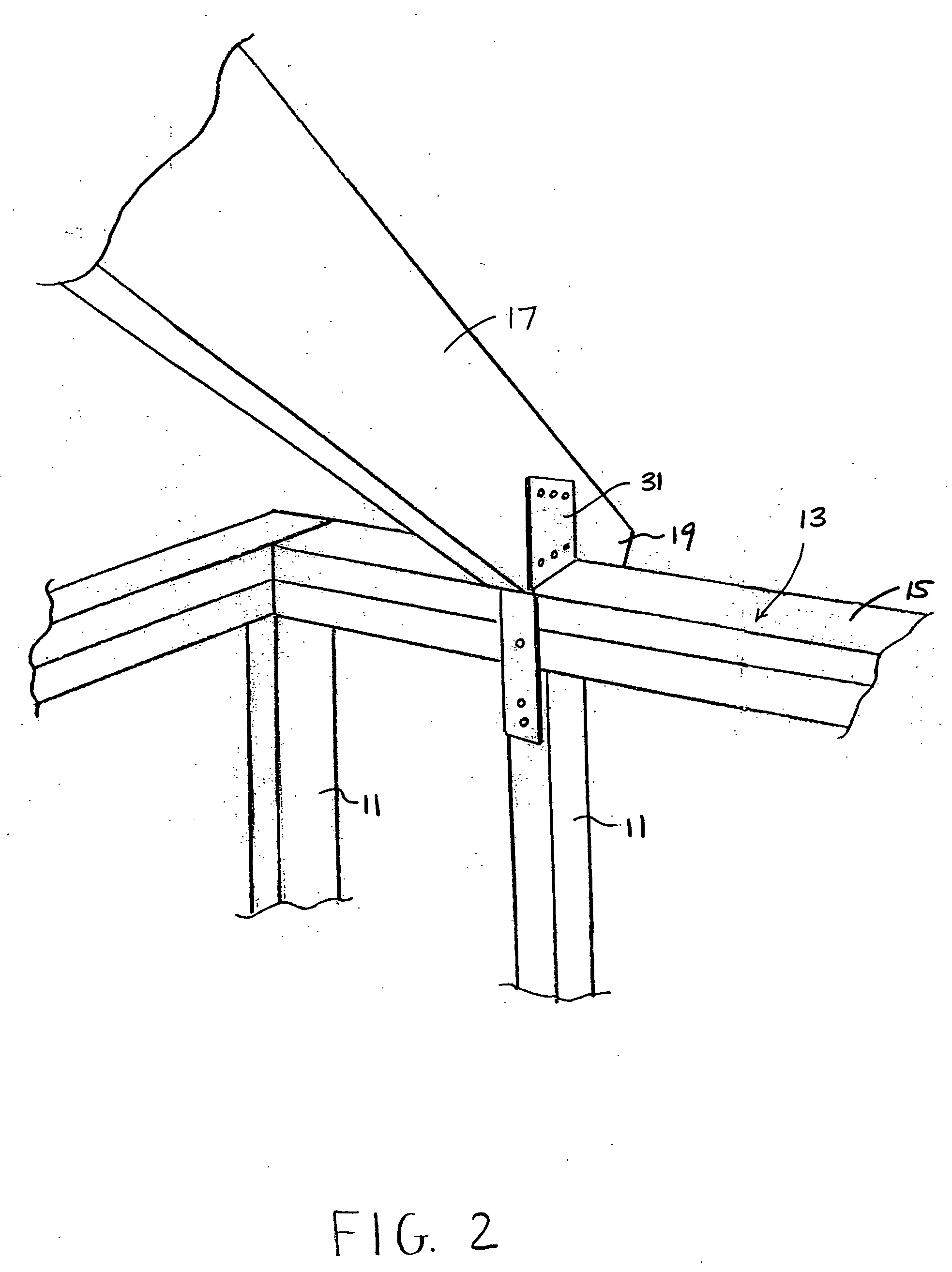

[0025] Referring now to FIG. 2, there is shown a tie which is constructed according to the teachings of the present invention, the tie being identified generally by reference numeral 31. As will be described further in detail below, tie 31 is designed to help secure together a vertically disposed, elongated wooden stud 11, a horizontal top plate 13 (represented herein as being in the form of a pair of stacked 2×4 wooden beams 15) and a rafter 17 (represented herein as being in the form of a single 2×6 wooden beam). Together, stud 11, top plate 13 and rafter 17 partially define the support structure, or framing, for a building.

[0026] Referring now to FIG. 3, there is shown a flat pattern layout, or blank, of tie 31 prior to bending, tie 31 preferably being constructed from a rigid, durable and strong piece of sheet metal, such as an 18 gauge galvanized steel or an 18 gauge 316 stainless steel.

[0027] Tie 31 comprises a rectangularly-shaped base 33 which serves as the main plate for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com