Coupling for joining two pipes

a technology of coupling and pipe, applied in the direction of couplings, pipe joints, flanged joints, etc., can solve the problems of joint loosening, inability to withstand the high temperature of fluid or pipes, and in the vicinity of a very hot object, so as to facilitate the opening of the coupling, increase the protection against the spread of the rings, and facilitate the effect of coupling opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

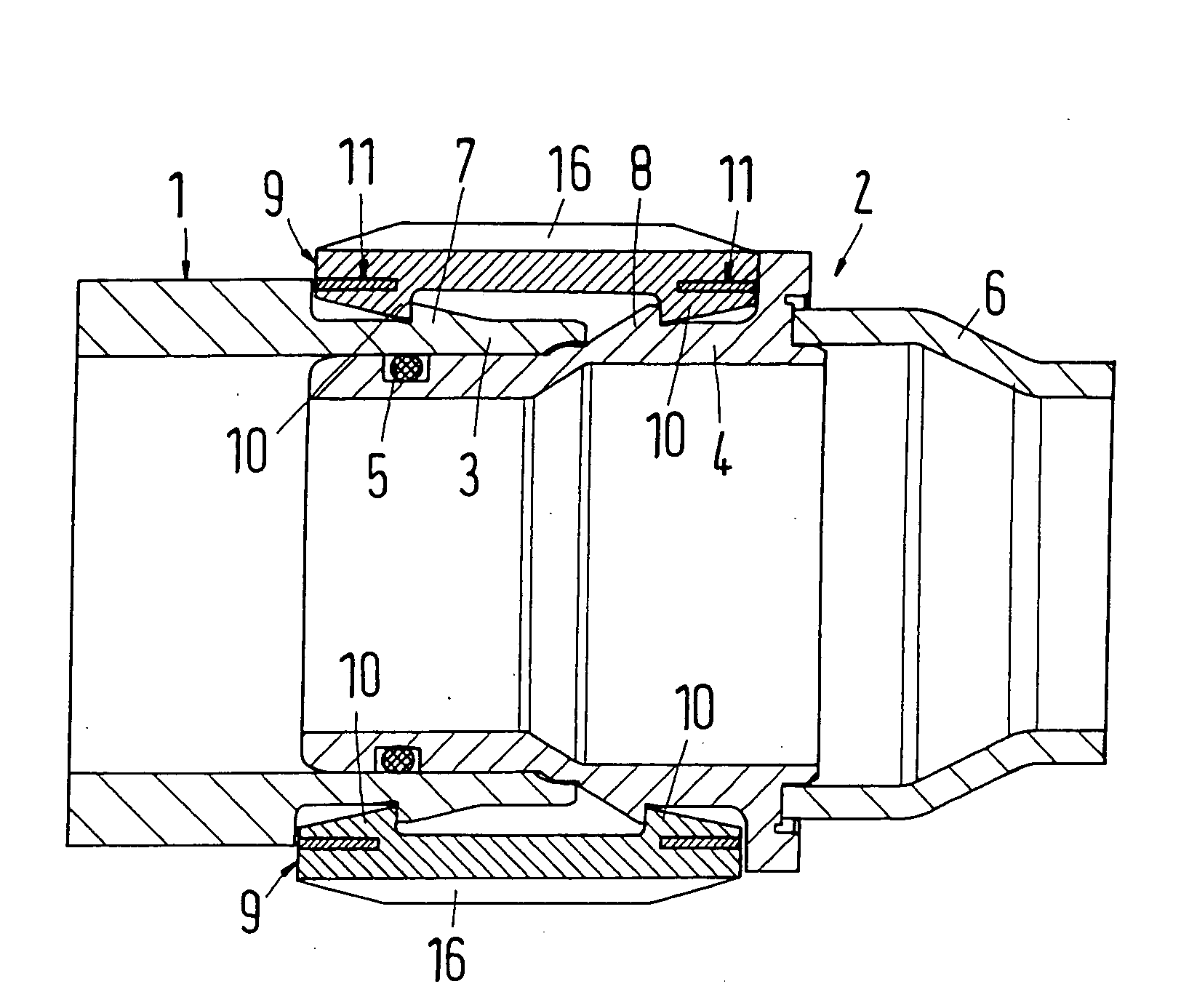

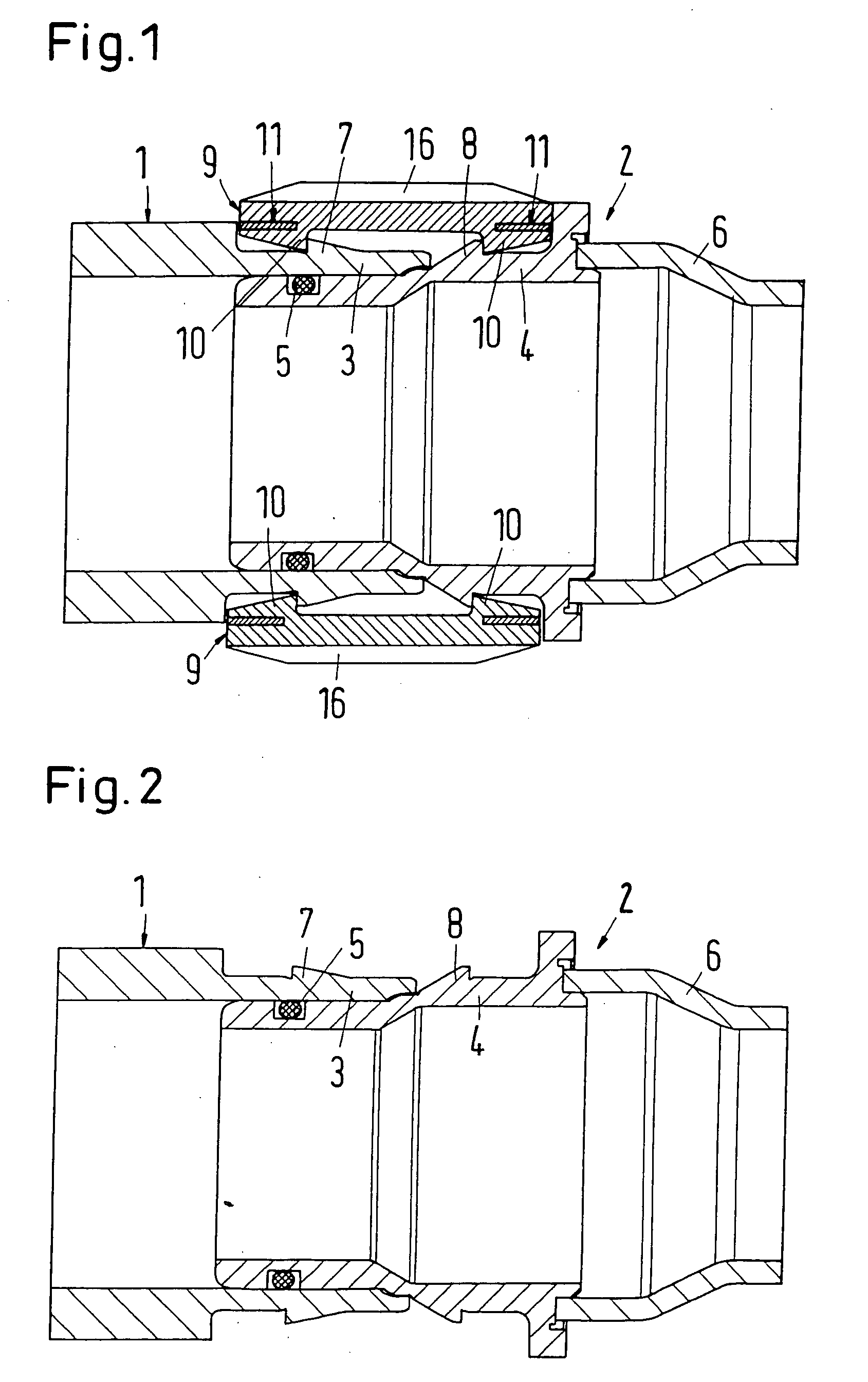

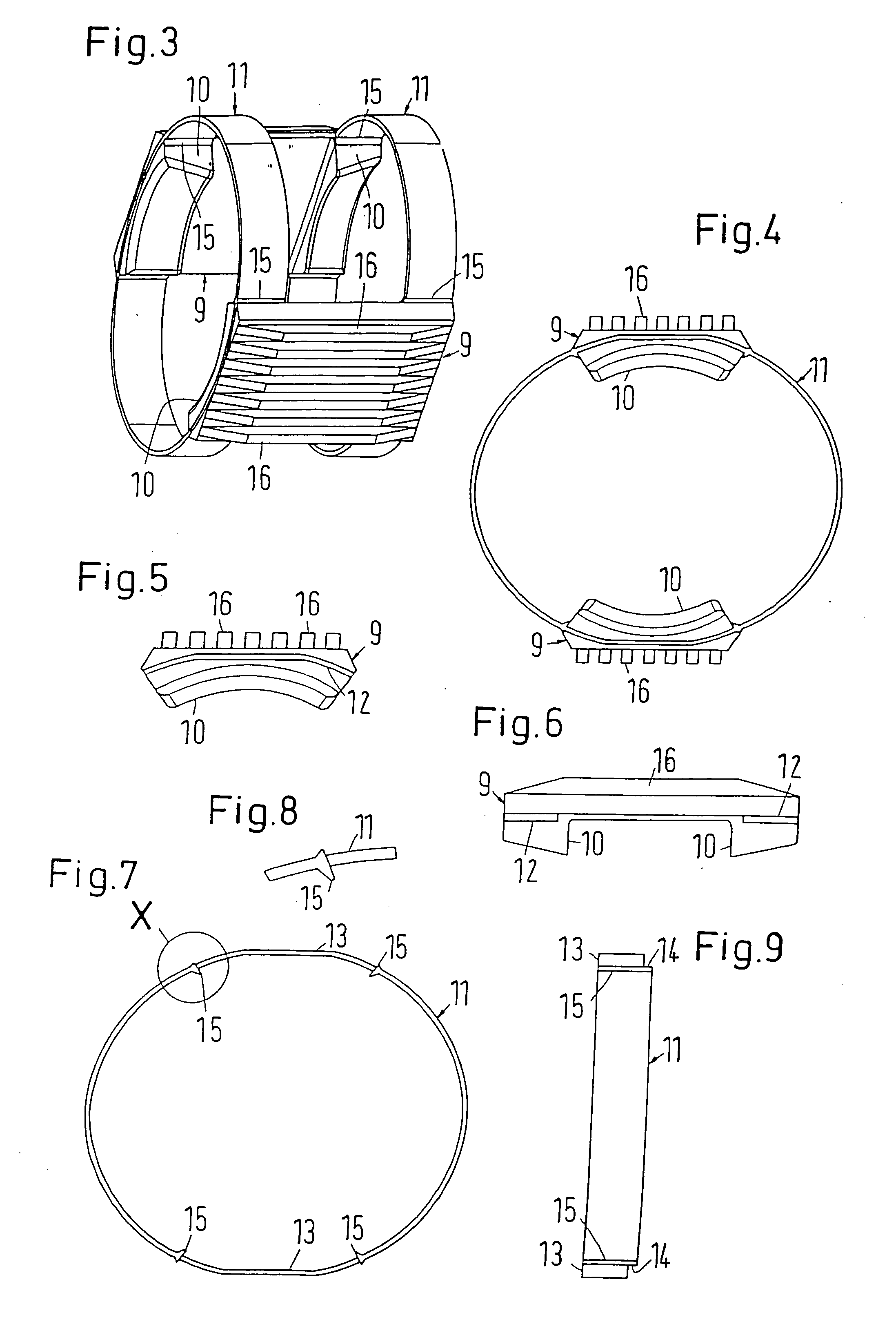

[0061]FIG. 1 and FIGS. 3 to 9 show a specific embodiment of the coupling of the invention and its individual parts. The coupling is used to join two pipes 1 and 2, which are made of a thermoplastic material or metal and are only partially shown in the drawings. Pipes 1 and 2 are shown in FIG. 2 without the coupling. The end sections 3 and 4 of the pipes 1 and 2 are inserted in the coupling and fitted together. The regions of the end sections 3 and 4 that are fitted together are sealed from each other by a gasket 5. The end section 4 is welded to the remaining part 6 of the pipe 2. Each end section 3 and 4 has a circumferential locking rib 7 and 8, respectively.

[0062] The coupling has radially inwardly projecting stop projections 10 at the ends of axial, flexurally stiff webs 9. The stop projections lock or snap in behind the locking ribs 7 and 8 when the end sections 7 and 8 are inserted in the coupling, and at the same time they fit together. For this purpose, the webs 9 are joine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com