Breech loaded fixed needle syringe and automatic injection device having the same

a technology of automatic injection and fixed needle syringe, which is applied in the direction of automatic syringe, ampoule syringe, intravenous device, etc., can solve the problems of increasing the damage to tissue at the injection site, more pain inflicted on the person receiving the injection, and the gauge of the needle for a syringe filled at the time of use is, typically, limited by the strength of the column, and the needle is long and thin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

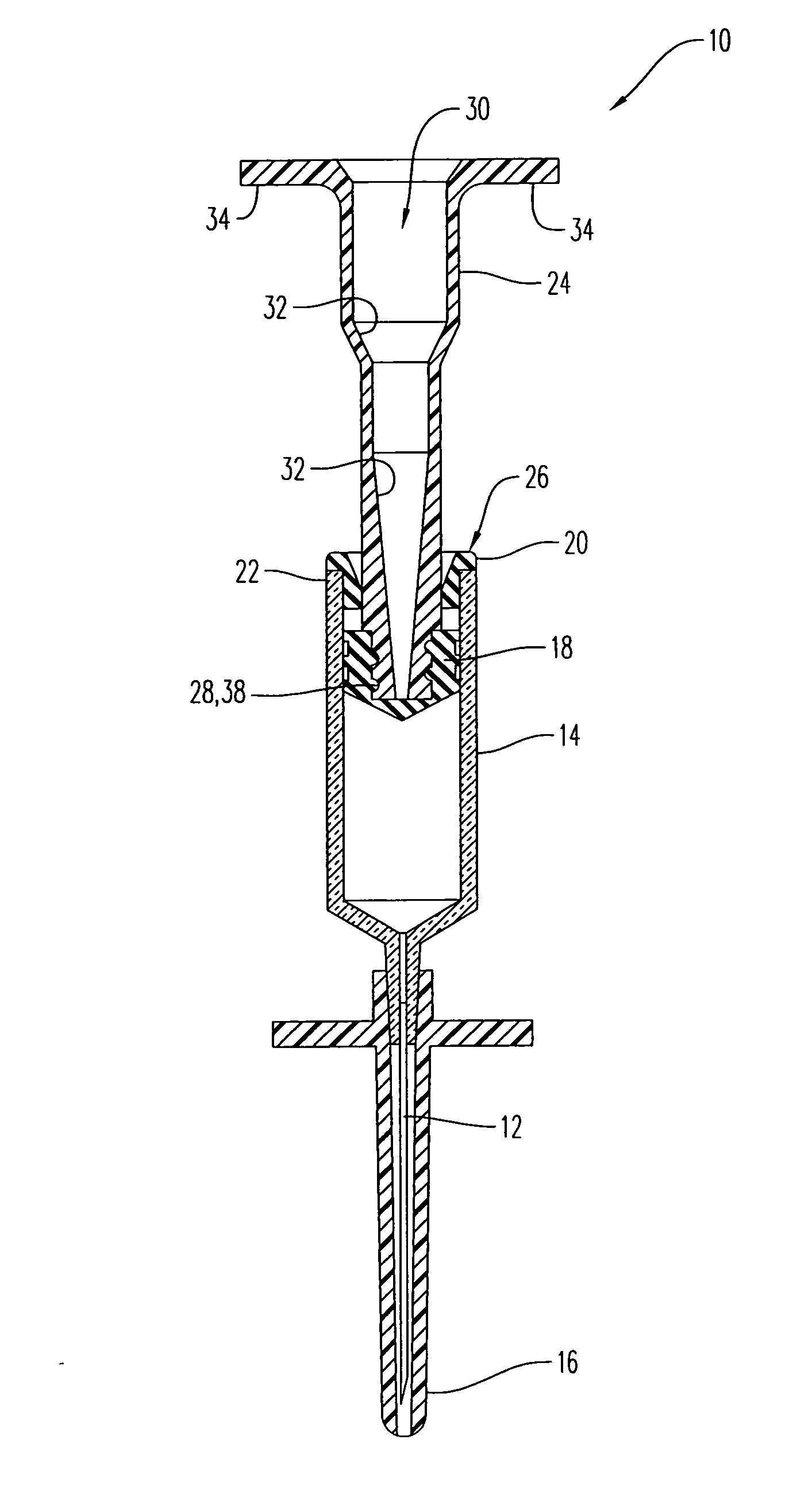

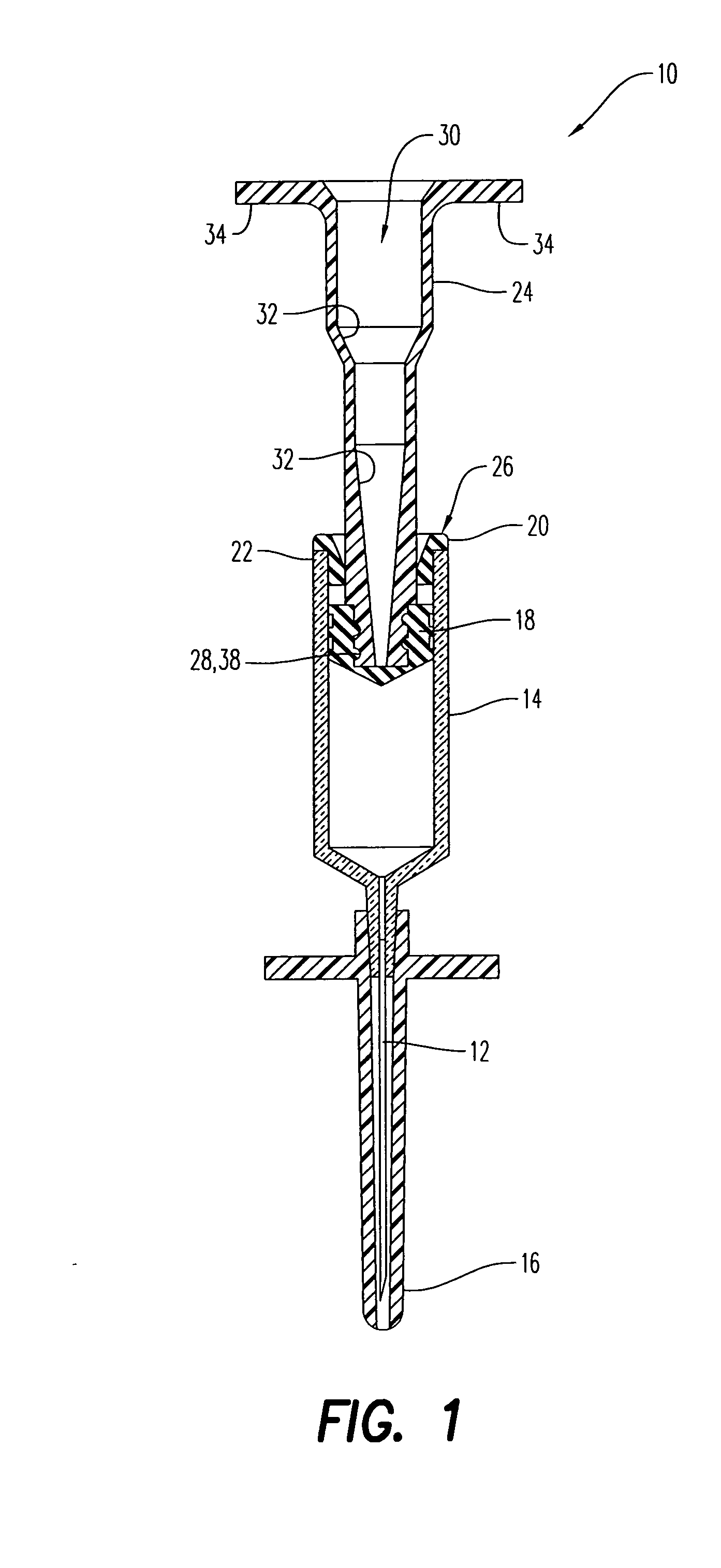

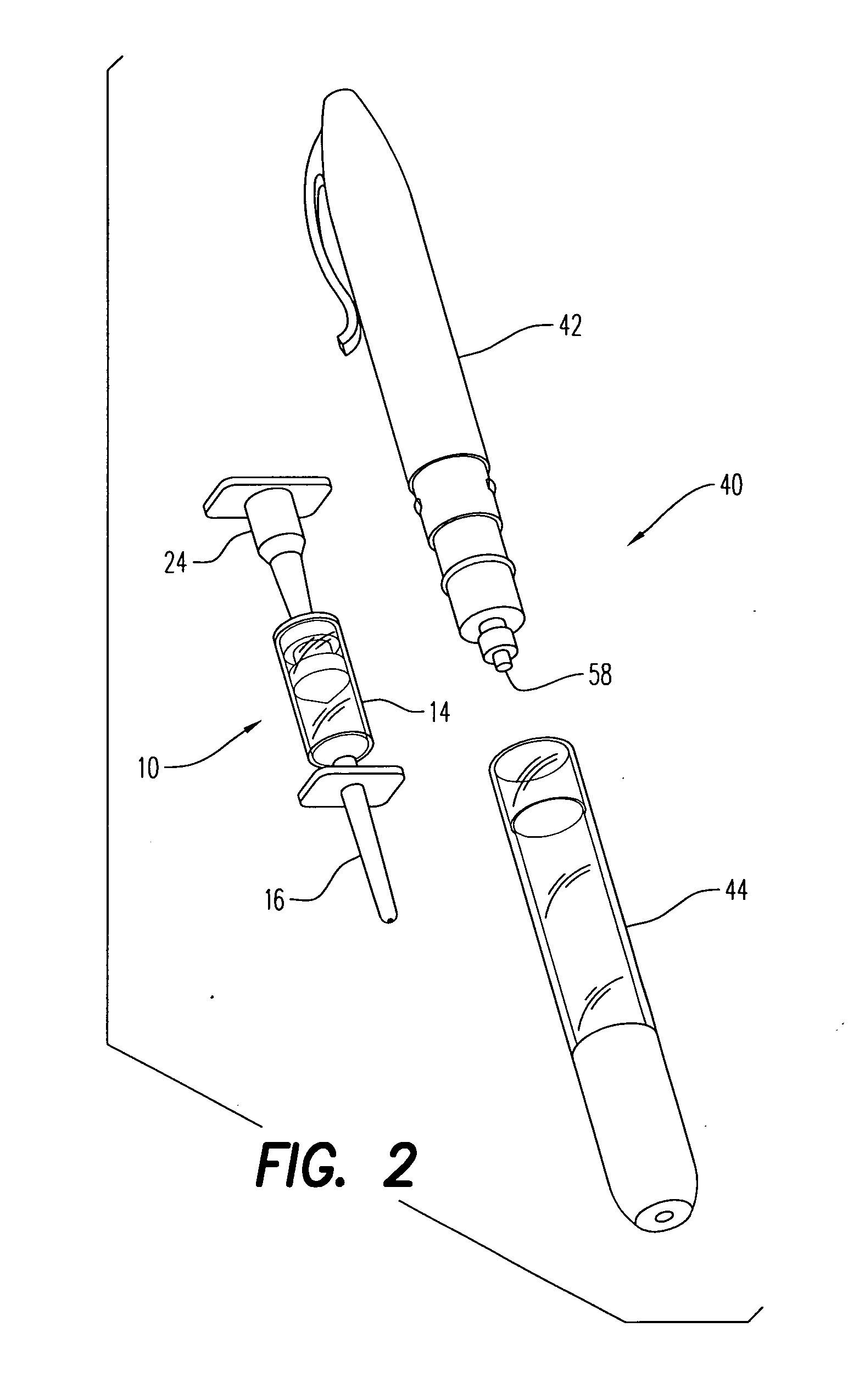

[0025] Referring to the figures and in particular to FIG. 1, an exemplary embodiment of a fixed needle syringe 10 according to the present disclosure is shown. Syringe 10 includes a hypodermic needle 12 in fluid communication with a medicine compartment 14. In some embodiments, syringe 10 can include a removable protective cover 16 disposed over hypodermic needle 12.

[0026] Syringe 10 also includes a piston 18 slideably disposed in medicine compartment 14. Preferably, syringe 10 includes a syringe end cap 20 at a breech end 22 of medicine compartment 14 to prevent inadvertent withdrawal of piston 18 from the medicine compartment.

[0027] Advantageously, syringe 10 is configured so that compartment 14 can be filled with medicine through piston 18.

[0028] It has been determined by the present disclosure that the size of the hypodermic needle is limited by the forces imposed on hypodermic needle 12 during aspiration. Advantageously, syringe 10 disassociates the forces imposed on hypoder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com