Modular heel assembly for high heel shoes

a module and high heel technology, applied in the direction of heels, wear-resisting attachments, fastenings, etc., can solve the problems of high heel shoes that are difficult to wear, the level surface is prone to perils for the wearer, and the wearer is often fatigued and uncomfortable, so as to increase the area of the shoe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Stiletto Shoe with Assembly for Receiving Modular Wedge Apparatus

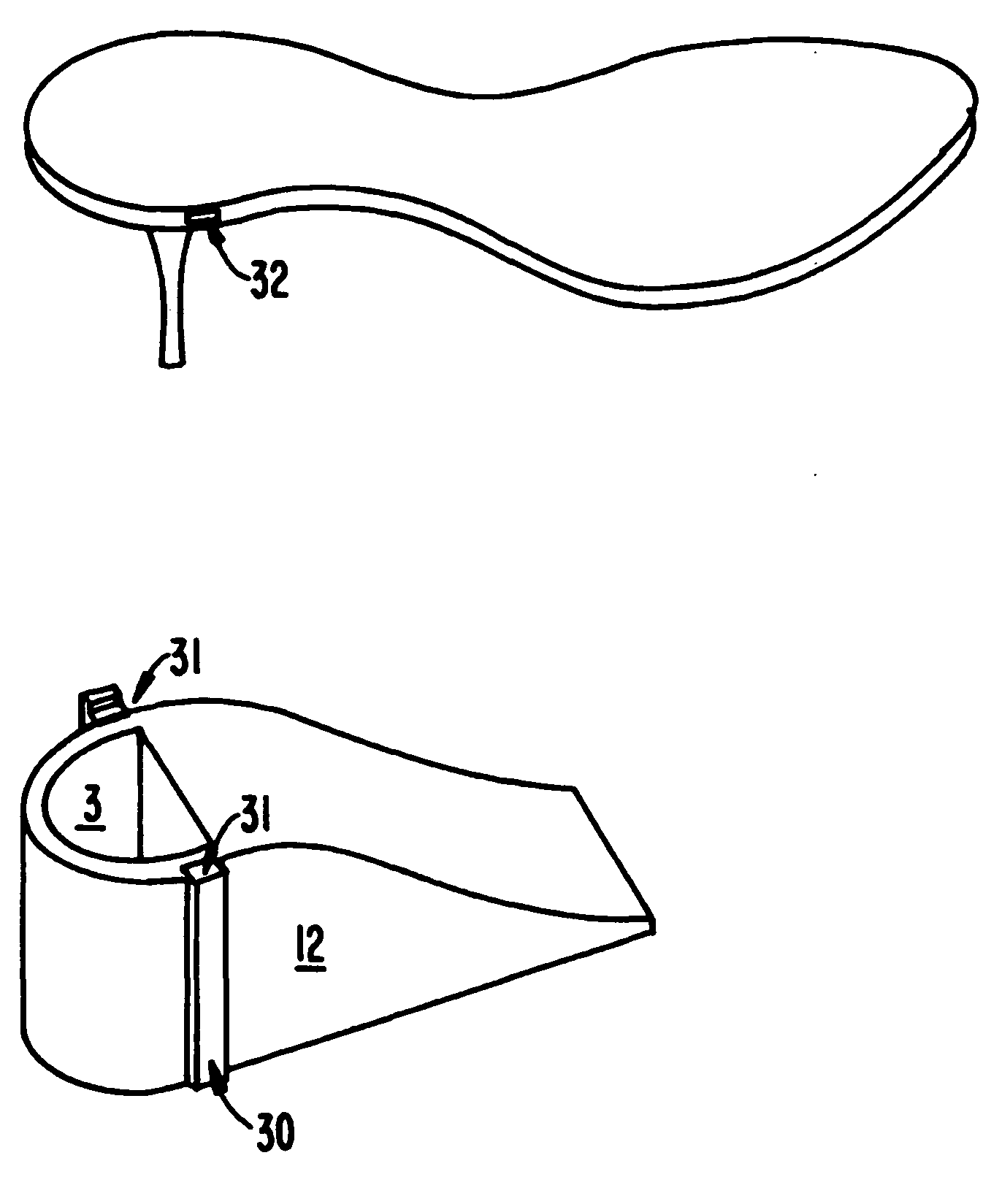

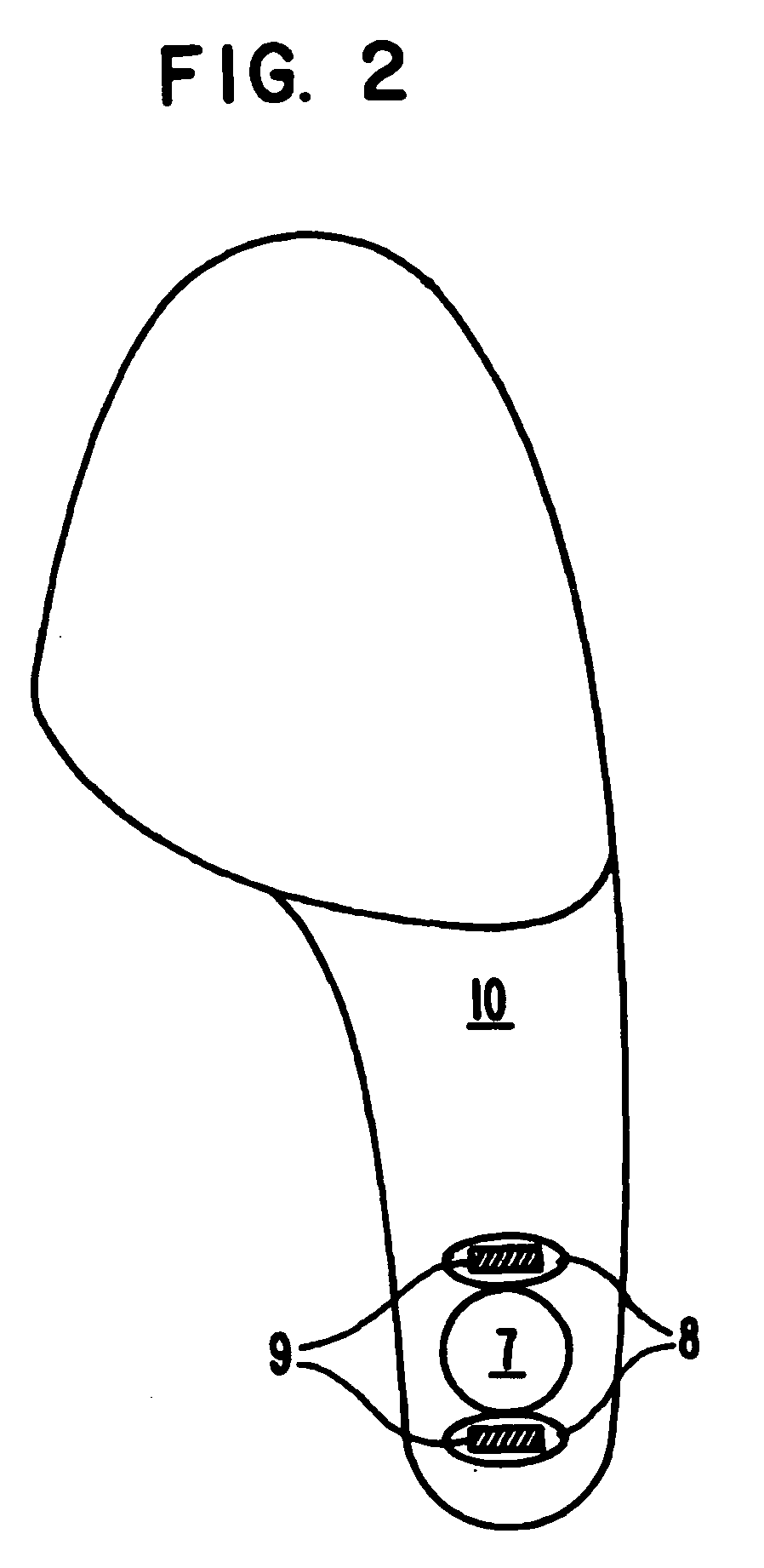

[0041] In this embodiment of the invention, grooves have been manufactured into the body of the shoe that is designed to accept protrusions of the modular wedge. FIG. 5 presents a schematic cross-sectional view of the bottom portion of the shoe (10) which contains a groove (14) in the posterior section of the body of the shoe under the ball of the foot. This groove may be in the outsole, or may start in and pass through the outsole and end within the midsole of the shoe. The modular attachment (12) includes a tongue-like protrusion (15), manufactured contiguous with the modular heel that fits into the groove (14). This groove adaptation is also depicted in FIG. 6, which presents a view from below of the shoe and modular heel assembly. FIG. 6 also shows that the shoe contains a groove at the top of the back of the heel (16), adapted to receive a posterior edge (17) of the modular attachment, depicted on FIG. 7. A close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com