Rotational set well packer device

a packer device and rotating technology, applied in the direction of sealing/packing, fluid removal, borehole/well accessories, etc., can solve the problems of inability to retrieve production tubing along with the tool string without resorting to costly fishing expedients, and the difficulty of unscrewing the components of the packer that unseat or relax the packer elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

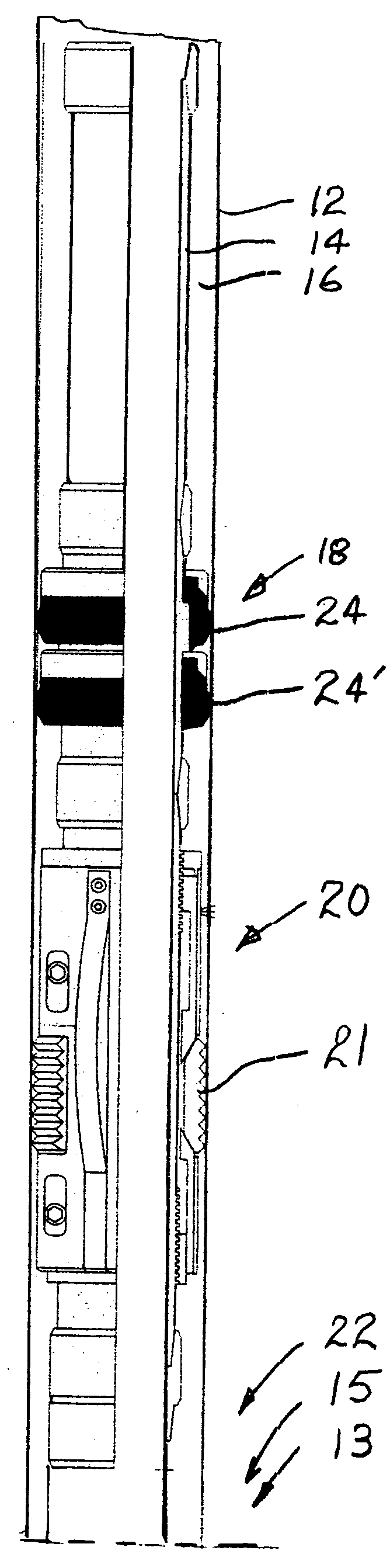

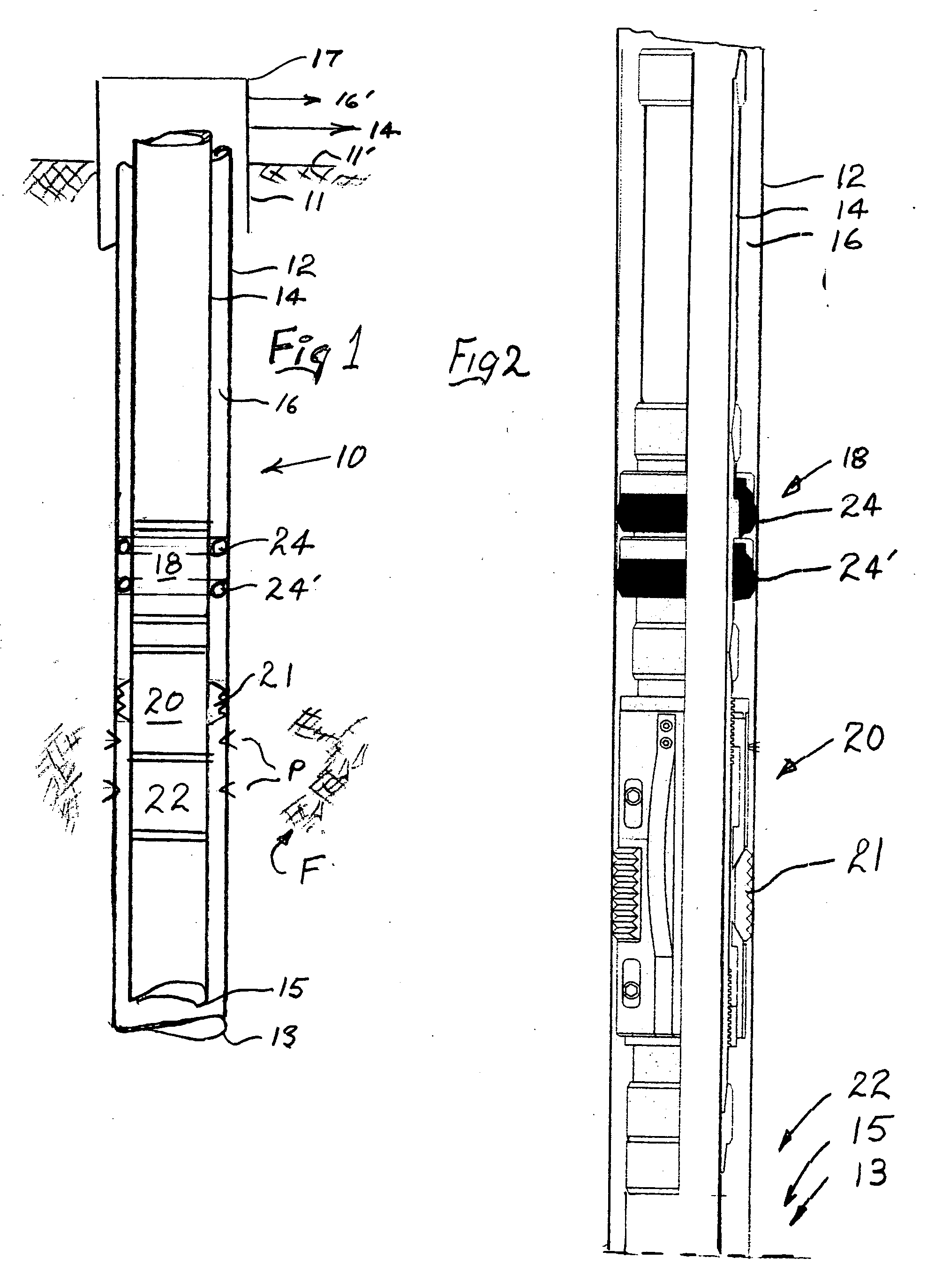

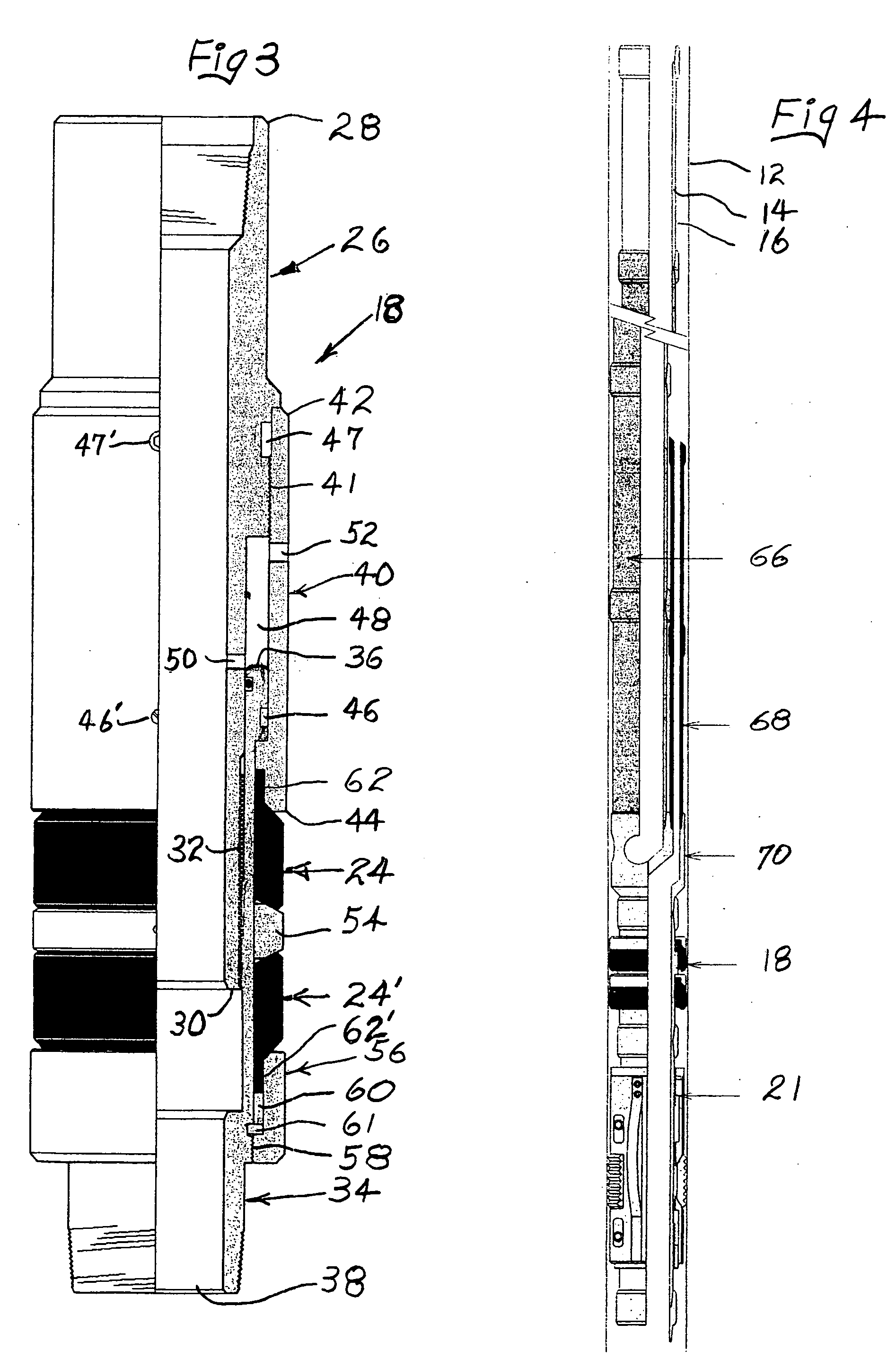

[0031]FIG. 1 of the drawings diagrammatically discloses a producing well bore 10 formed through the surface of the earth and extends downhole through a fluid producing formation F. There is a surface pipe or upper casing 11 for protecting the upper aquifer. Within surface casing 11 there is axially received a main well casing 12 extending downhole into proximity of the bottom 13 of the borehole. Production tubing 14 is also axially received respective casings 11 and 12. Accordingly, an annulus 16 is formed between casing 12 and tubing 14. Tubing 14 is a production pipe string, sometime referred to as a tool string for it is series connected respective to various oil field apparatus such as, for example only, the instant packer device 18, made in accordance with this invention, the details of which are more fully described later on herein.

[0032] The surface casing 11, well casing 12, and production tubing 14 are attached to a wellhead 17, also called a Christmas tree.

[0033] The tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com