Absorption refrigerator with ice-maker

a technology of refrigerator and ice maker, which is applied in the field of absorber refrigerator, can solve the problems of humidity transfer from the ice maker to the air, difficulty in achieving a high enough cooling power of the refrigeration system, and further increase of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] An exemplifying embodiment of the invention will now be described with reference to the accompanying drawings in which:

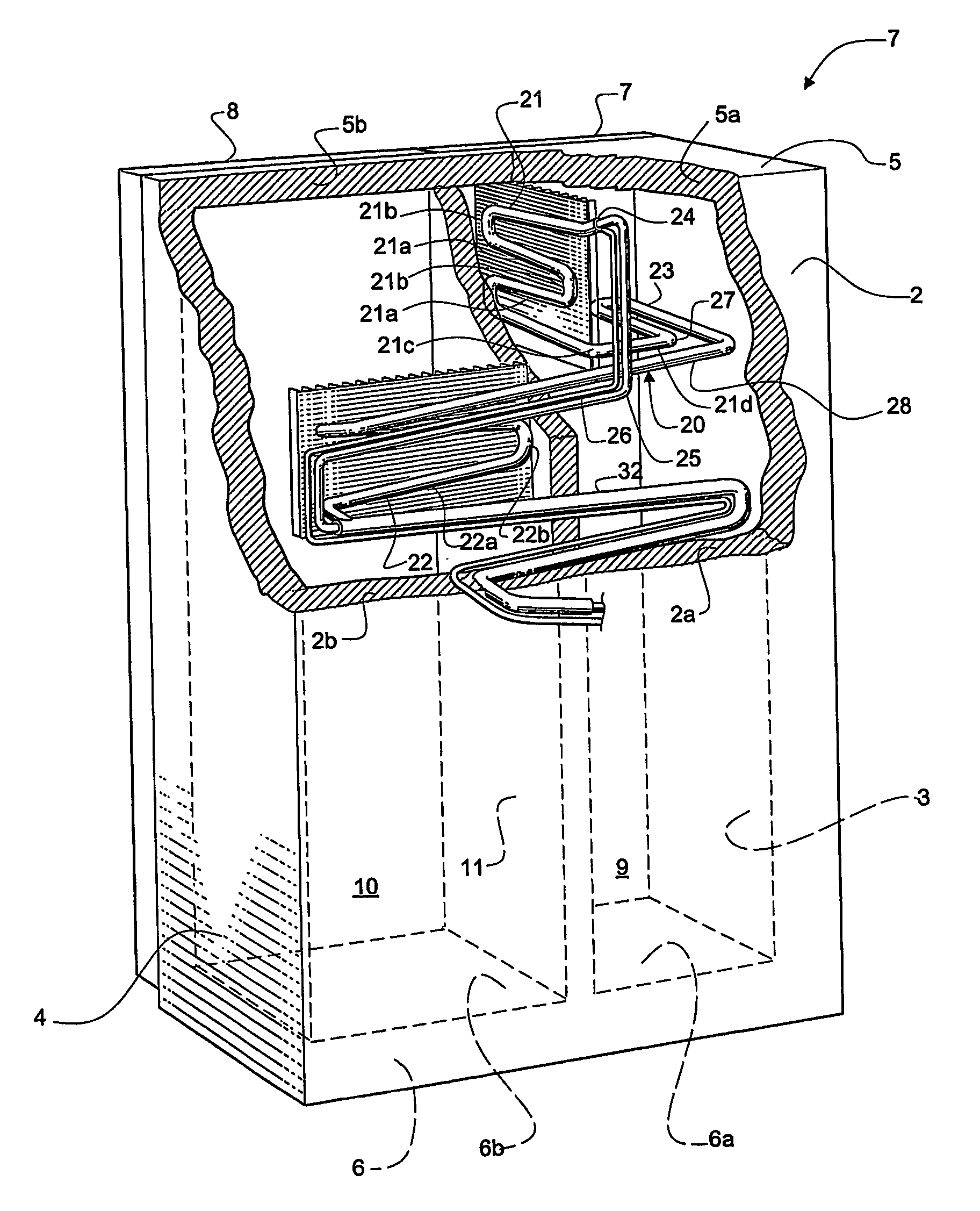

[0023]FIG. 1 is a top elevation view, with parts of the walls broken away, of a refrigerator cabinet according to the present invention.

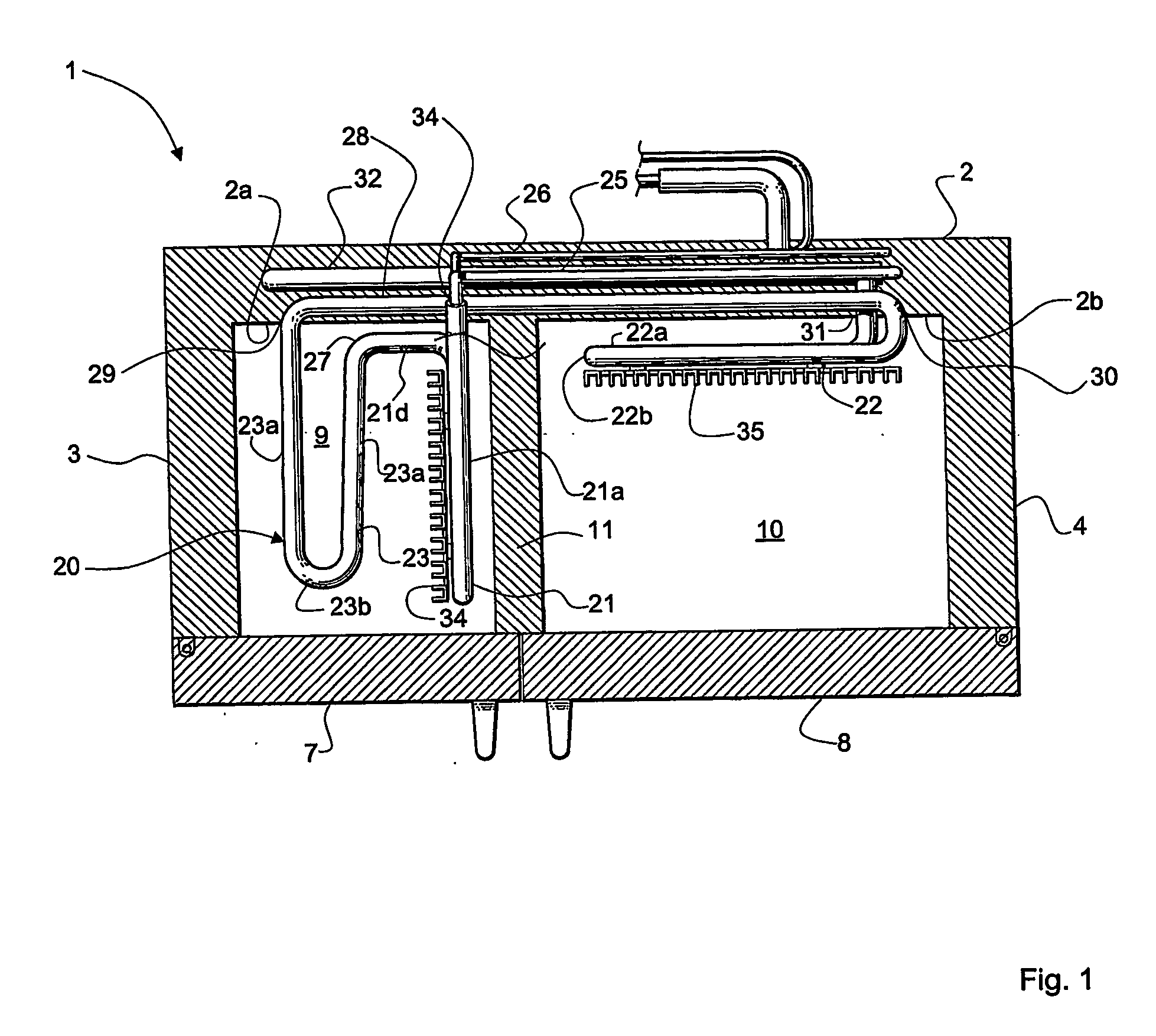

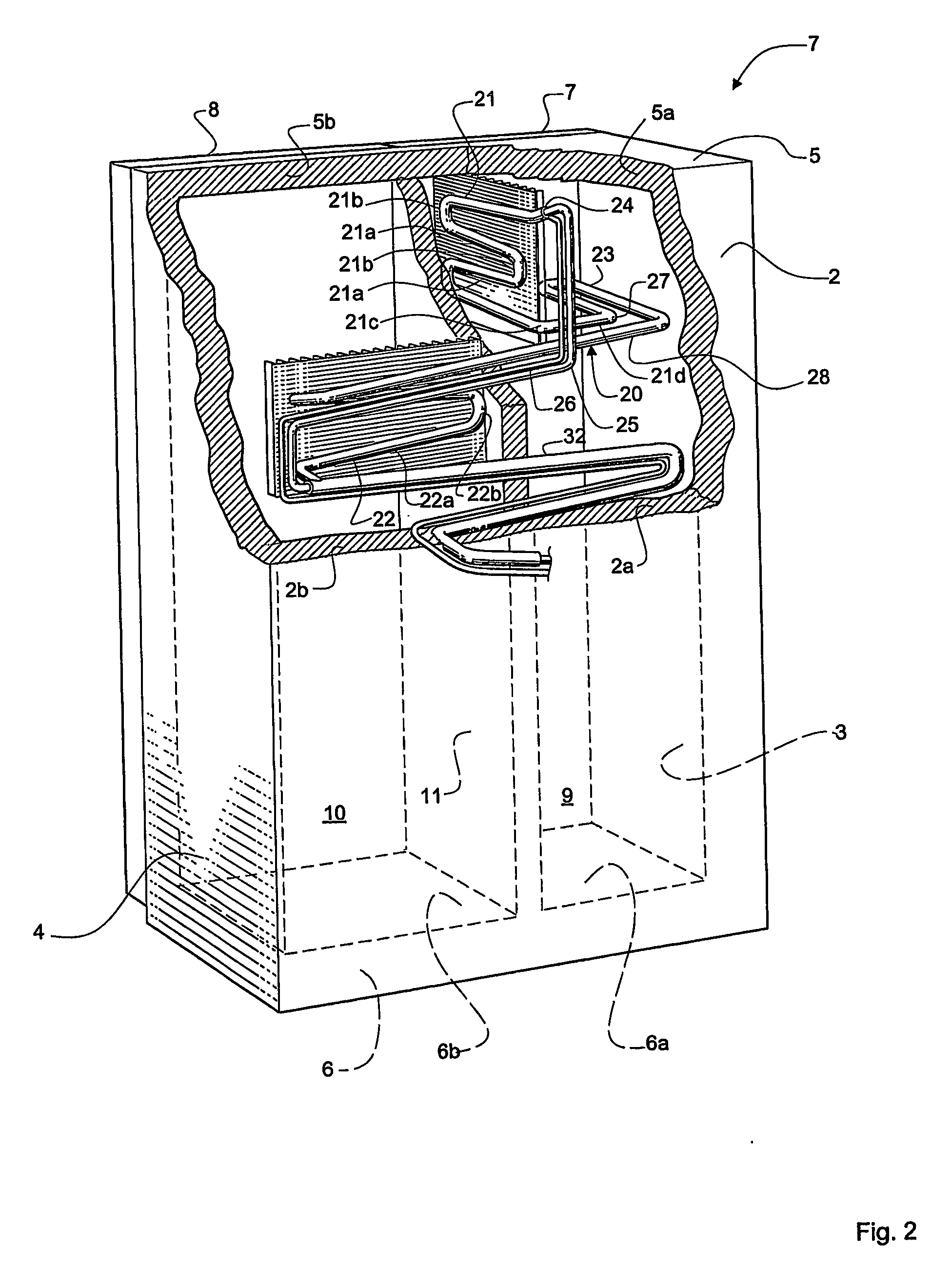

[0024]FIG. 2 is a perspective view from behind, with parts broken away, of the refrigerator in FIG. 1.

[0025] In the figures a side-by-side absorption refrigerator 1 is shown. The cabinet includes a rear wall 2, two side walls 3, 4, a top-wall 5 and a bottom-wall 6. These outer walls 2-6, together with two front doors 7, 8 enclose a low temperature storage compartment 9 and a higher temperature storage compartment 10. The outer walls 2-6 and the front doors 7, 8 all include an outer and an inner shell between which heat insulating material, such as polyurethane foam, is arranged. The two compartments 9, 10 are hermetically sealed from each other by a vertical partition wall 11, which extends perpendicular to and from the rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com