Laminated flat mophead

a mop head and foam technology, applied in the field of foam mop heads, can solve the problems achieve the effects of reducing the potential contamination of the cleaning site, increasing durability, and reducing the particle removal of the mop head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

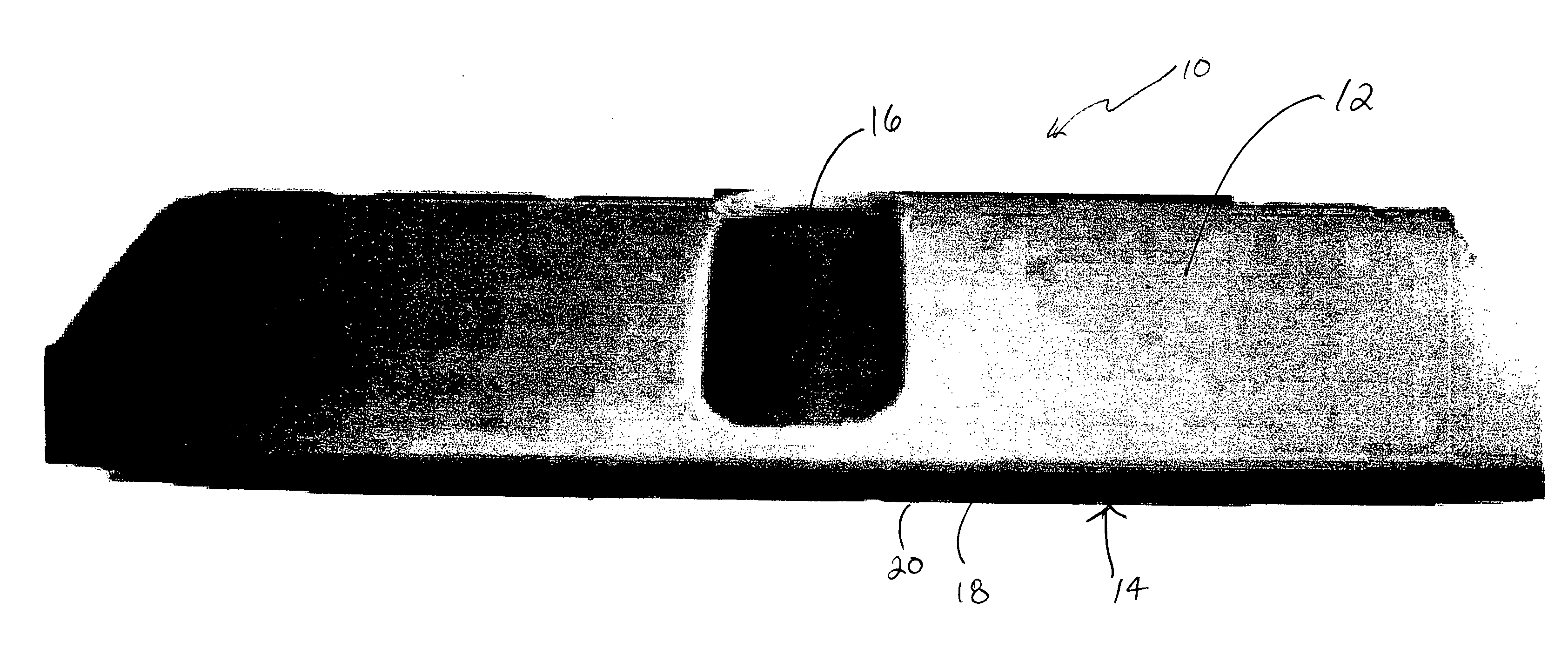

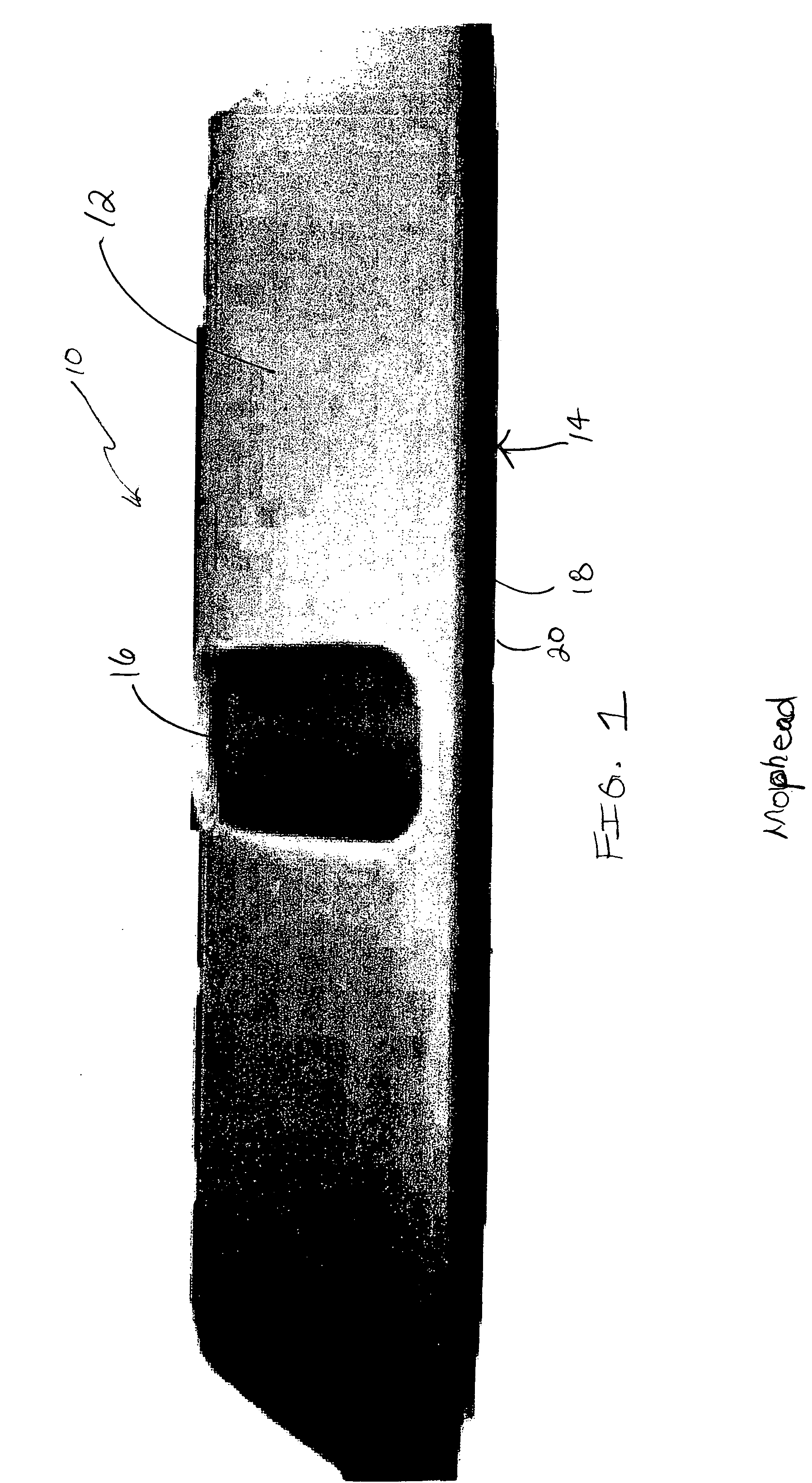

[0010]FIG. 1 shows a top perspective view of a flat mop head 10 in accordance with the invention. Flat mop head 10 includes a top 12 and a bottom 14. Top 12 of flat mop head 10 also includes an opening 16 for a mop handle (not show) which enables flat mop head 10 to be securely attached to the mop handle during use. Flat mop head 10 further includes a flat foam layer 18 and at least one fabric material 20 laminated to the flat foam layer 18 without using glue. Fabric material 20 may be laminated to the top and / or bottom of flat foam layer 18 but is preferably at least laminated to the bottom of the flat foam layer 18 which comes into contact with the surface to be mopped or cleaned.

[0011]FIG. 2 is a bottom perspective view of the flat mop head 10 shown in FIG. 1 with a laminated double-knit snag-resistant polyester fabric 22 attached to the bottom of the flat mop head and FIG. 3 is a bottom perspective view of the flat mop head 10 shown in FIG. 1 with a laminated micro fiber textil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| durable | aaaaa | aaaaa |

| durability | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com