Laminated foam mophead

a foam mop and foam technology, applied in the field of foam mop heads, can solve the problems of reducing the potential contamination of the cleaning site, and achieve the effect of increasing durability and decreasing particle removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

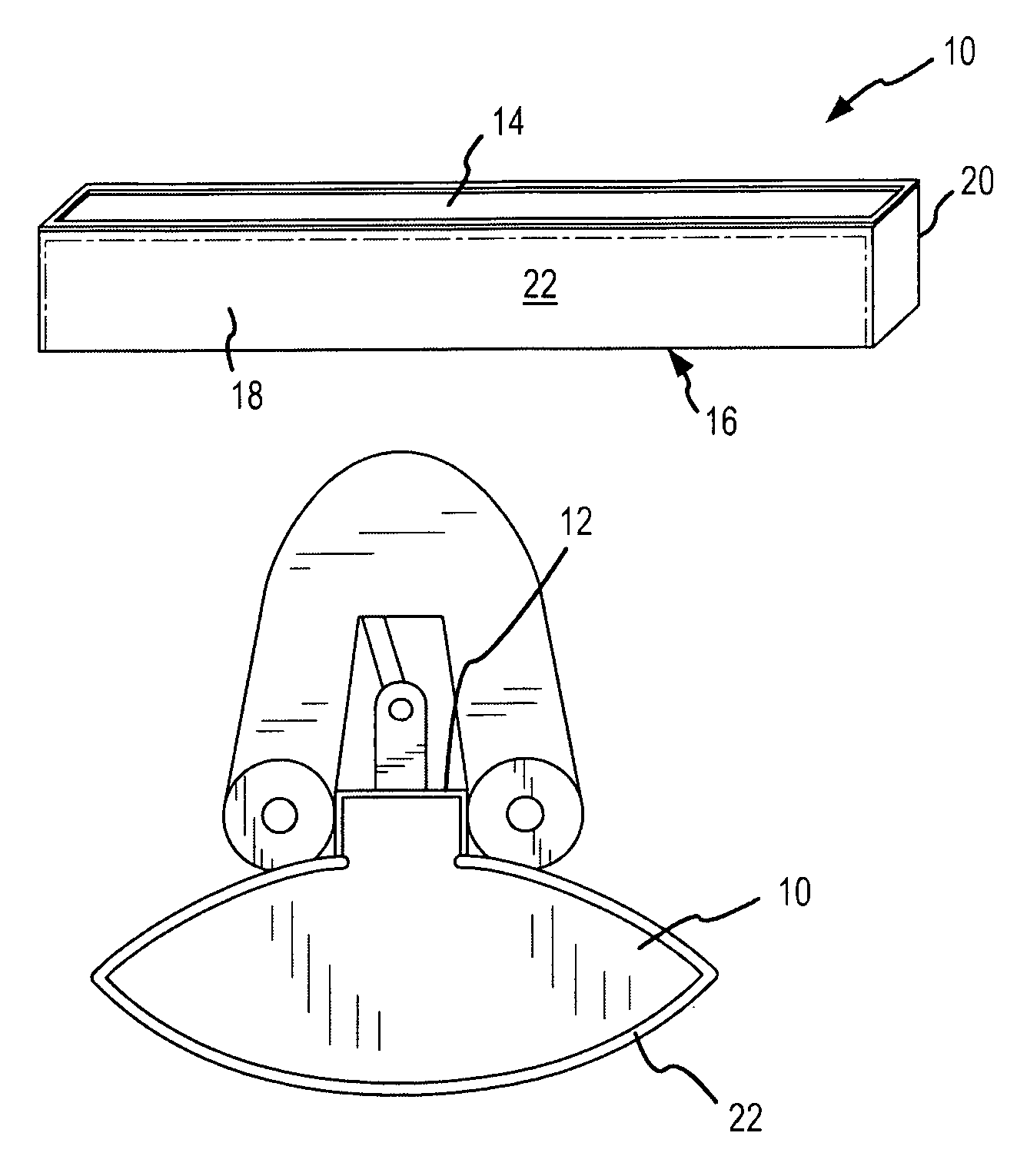

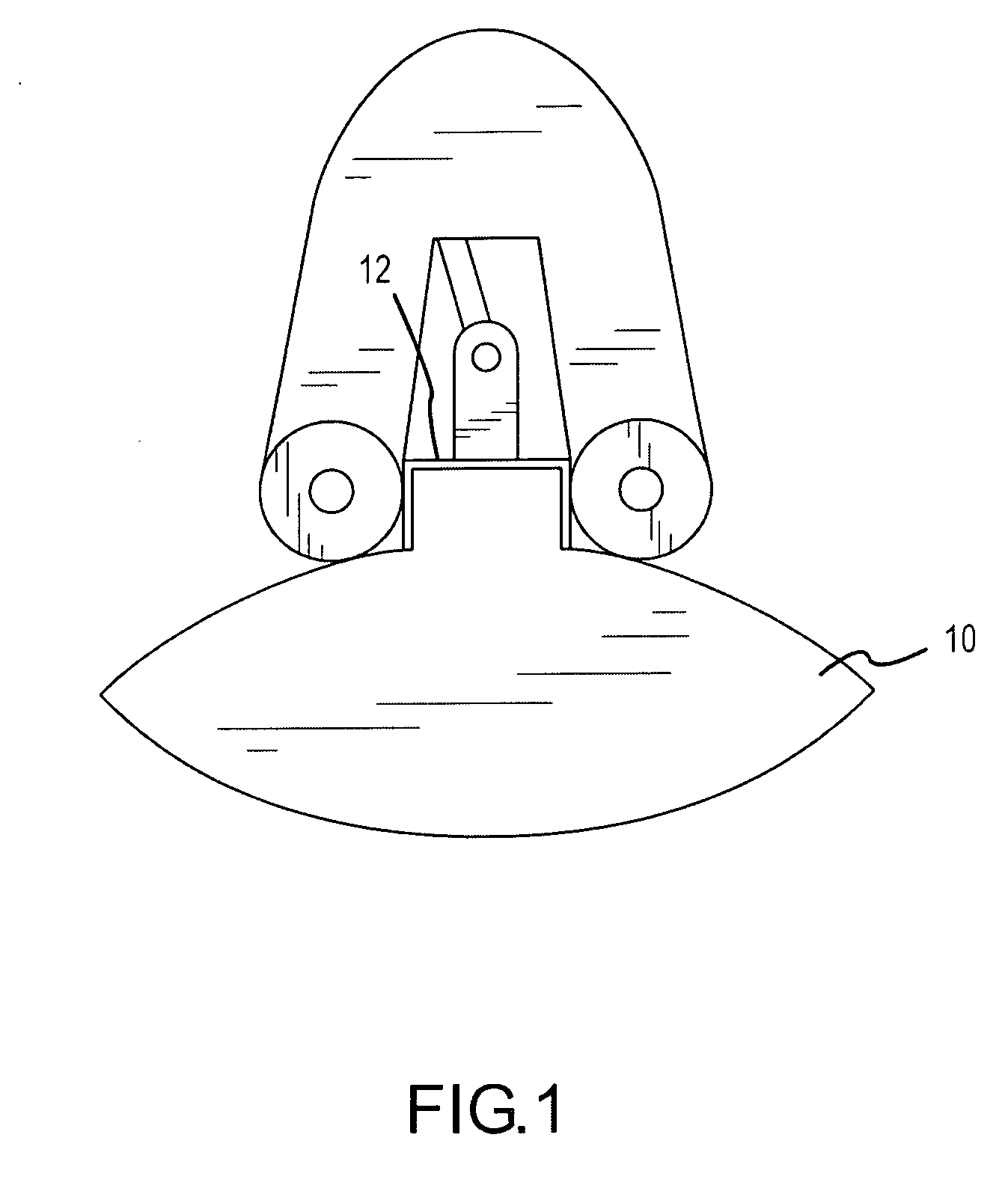

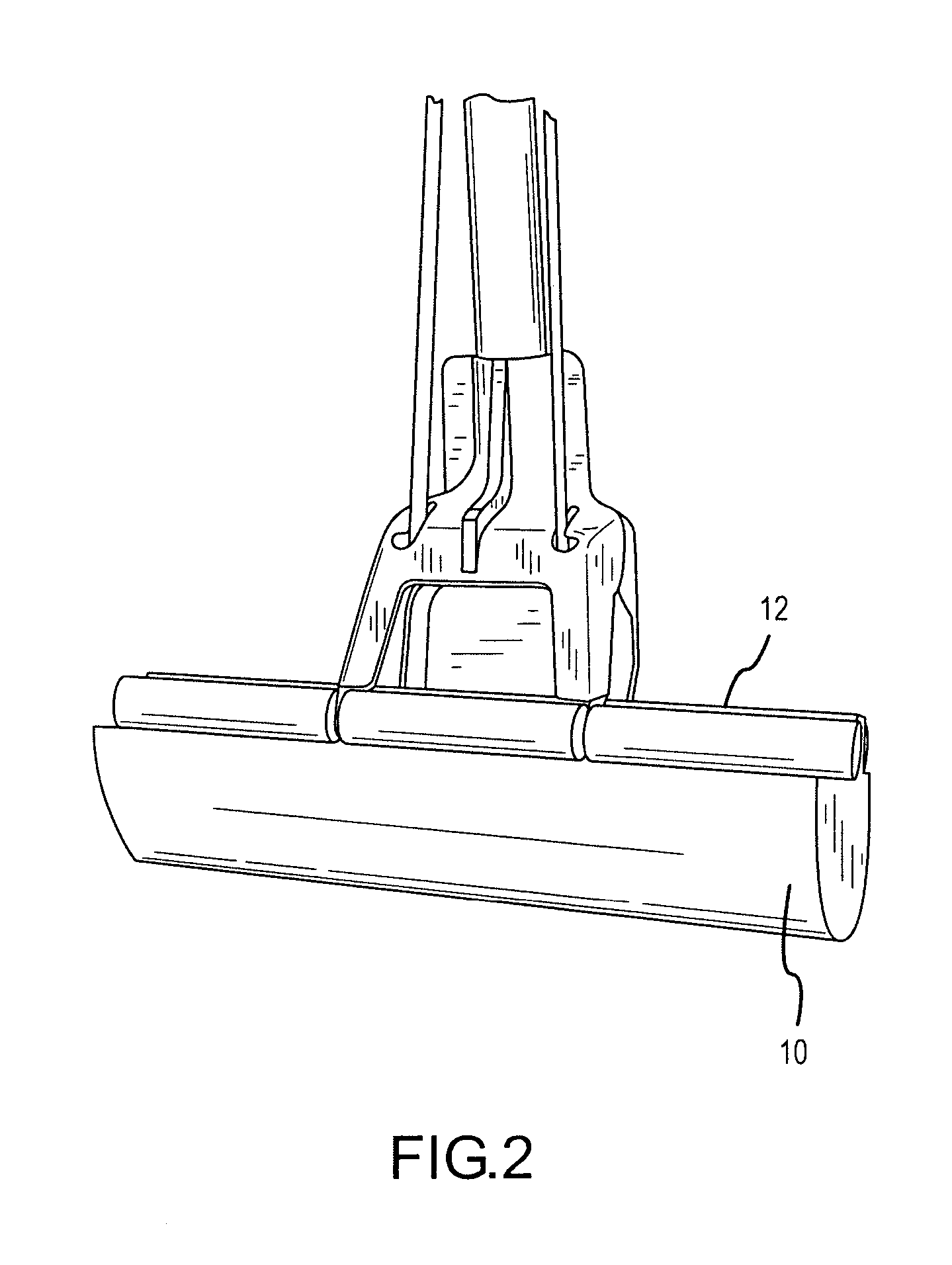

[0011]FIG. 1 is a side perspective view of a mop head 10 in accordance with the invention. FIG. 3 is a schematic showing lamination with a micro-fiber on three sides of the mop head shown in FIG. 1 before installation of the stainless steel bracket 12 shown in FIG. 1. Mop head 10 comprises a foam block having a top surface 14, a bottom surface 16, two side surfaces 18, and two end surfaces 20. At least one fabric material 22 is wrapped around, and laminated to the bottom surface 16 and side surfaces 18 of the foam block.

[0012] Fabric material 22 may be laminated to the bottom surface 16 and side surfaces 18 of the foam block by using any known means of uniting superimpose layers that does not include a glue or adhesive, such as, for example, heat and pressure applied to the superimposed layers. A stainless steel bracket (as shown in FIGS. I and 2) is attached to the top surface 14 of the foam block such that the bottom surface 16 and side surfaces 18 of the foam block are drawn upw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com