Manually held dental flossers

a technology of flossing holder and flossing ring, which is applied in the field of tooth flossing, can solve the problems of inability to floss daily, inconvenient use, and inability to adhere to flossing daily, and achieve the effect of reducing spring force and improving leverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

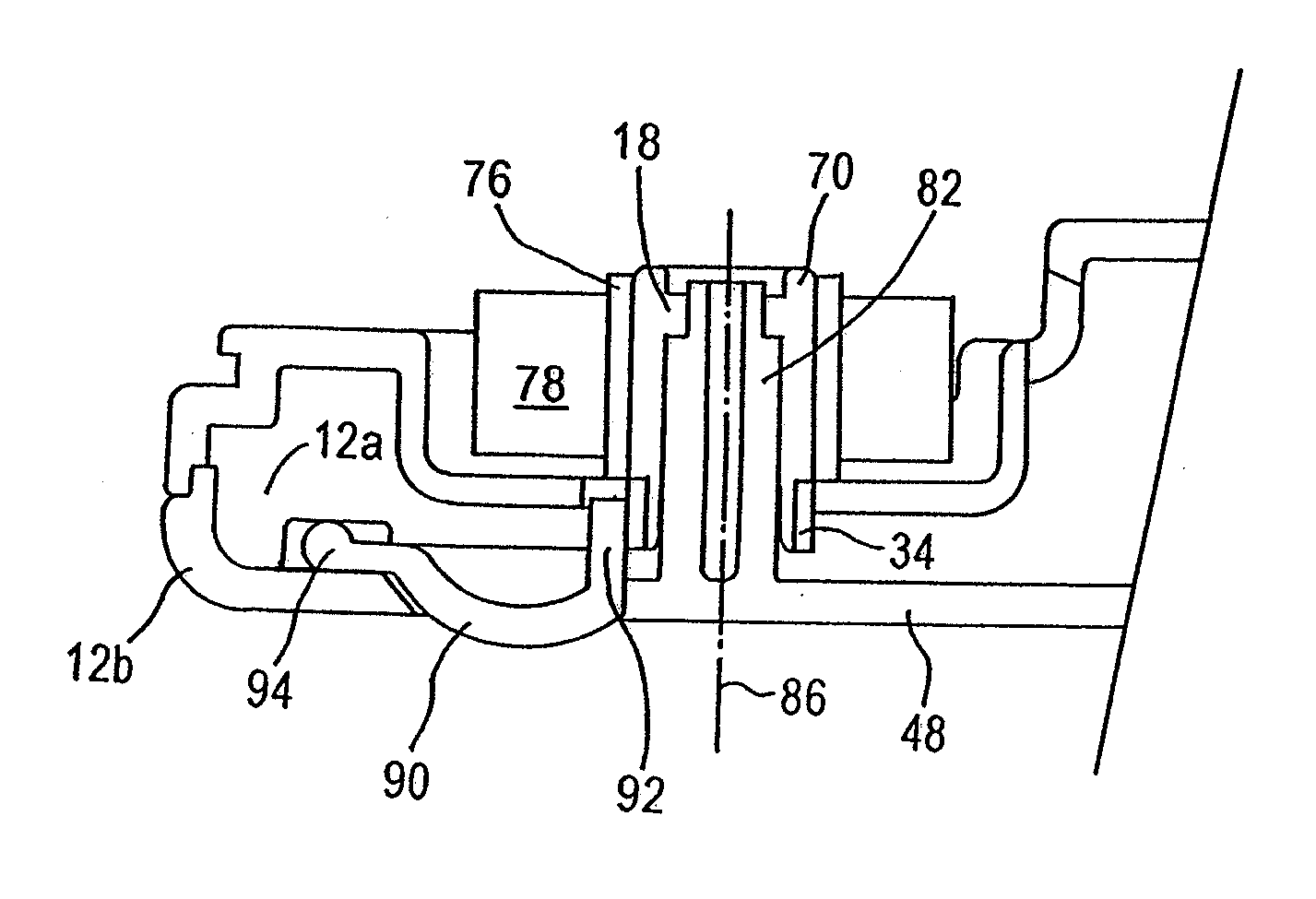

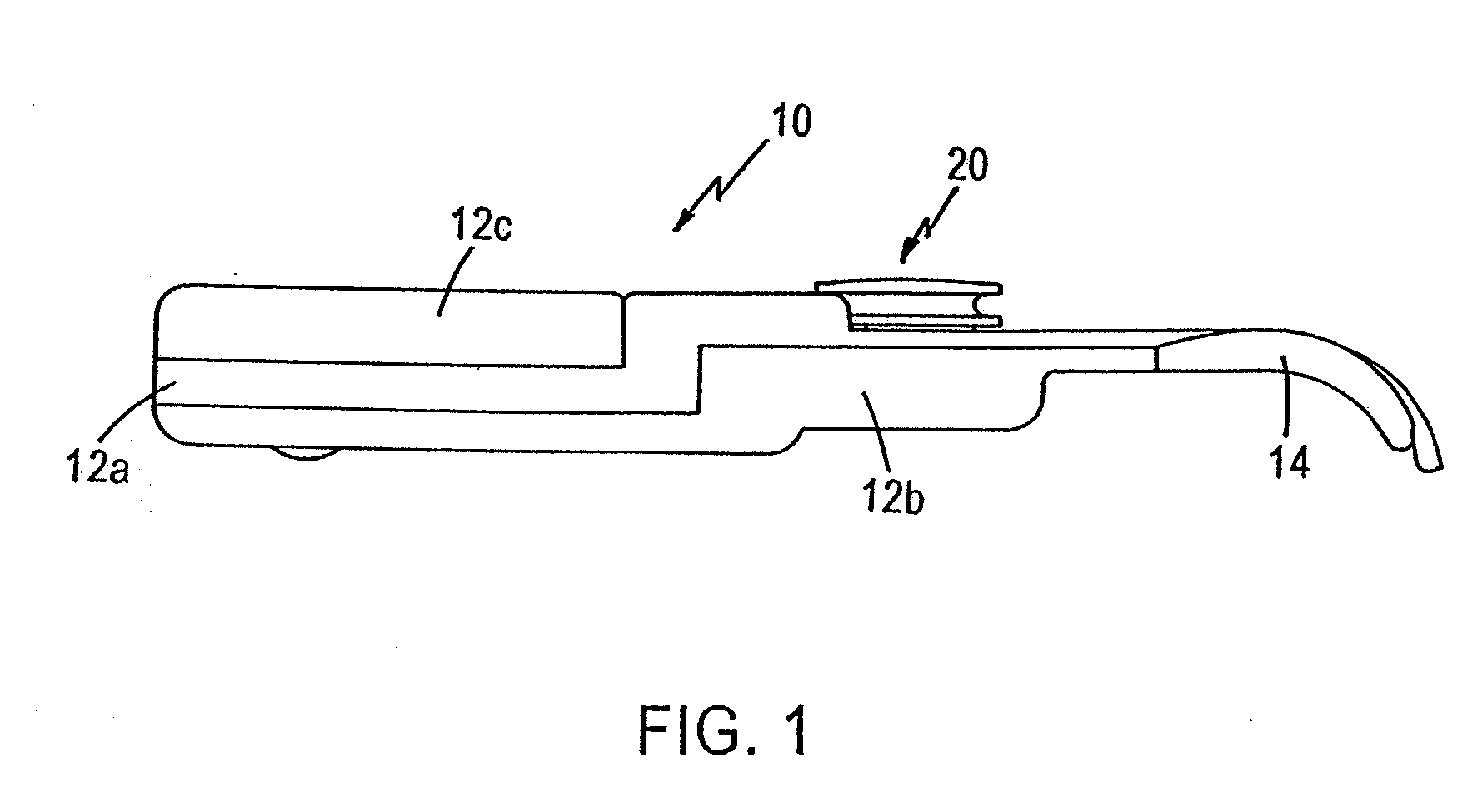

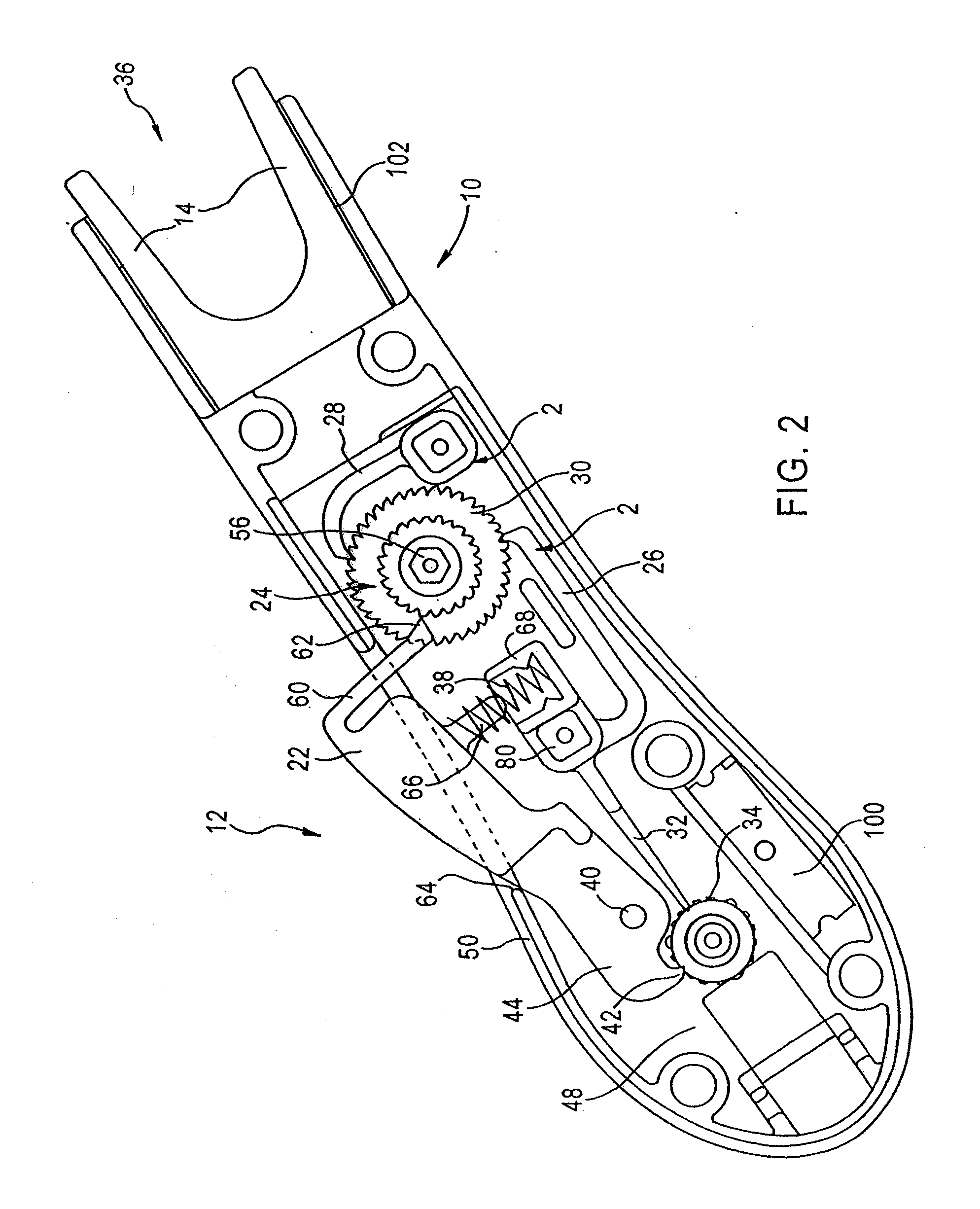

[0031] Referring to FIGS. 1 and 2, there is disclosed a manual dental flosser 10 having a handle or body portion 12 formed from a top housing 12a and a bottom housing 12b from which bottom housing a pair of fork arms 14 project forwardly in laterally spaced relationship to each other. The handle 12 supports a floss supply spool 16 normally covered with a snap-on cover 12c. Supply spool 16 is uniquely mounted to a supply spool mounting post 18, and a take-up spool 20 is mounted forwardly (i.e. closer to the fork arms 14) of the floss supply spool in the novel manner described below. Manually depressing a trigger 22 projecting from a side of handle 12 is operable to partially rotate an input drive ratchet 24, co-rotatably mounted to the take-up spool 20, which in turn co-rotates the take-up spool in a counter clockwise direction. The take-up spool 20 is rotatable in one direction only, i.e. to wind used floss, and is preferably located advantageously above top housing 12a. Undesired r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com