Valve stem seal

A technology of sealing device and valve device, which is applied in the direction of valve device, shaft seal, valve lift, etc., can solve problems such as leakage, and achieve the effects of avoiding leakage, reducing friction loss, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

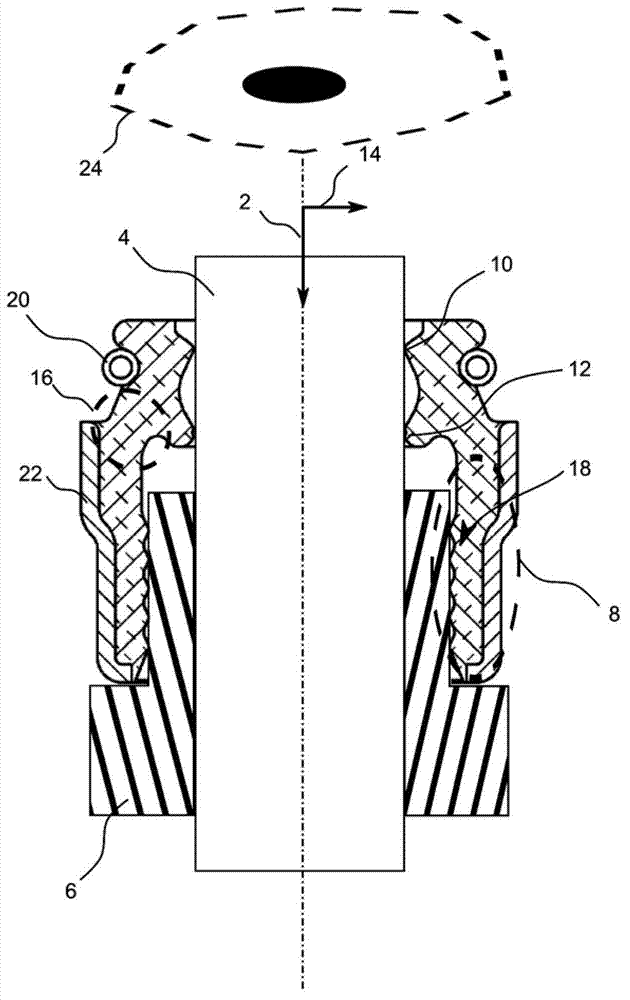

[0015] figure 1 The stem seal is shown in the installed condition. The valve stem sealing device is used for sealing the valve stem 4 moving along the axial direction 2 . The valves or valves are usually operated counter to the axial direction 2 and are not shown here for the sake of clarity, eg cam actuation. Movement along the axis 2 opens a valve crown or disc connected to the valve stem 4 on the extension of the axis 2 to open the inlet or outlet of the combustion chamber of the vehicle engine. As for the valve top or the valve disc and other mechanisms, for the sake of clarity of view, they are not shown and described in detail here, because those skilled in the art are well aware of them.

[0016] The valve stem 4 is guided by a valve guide 6 whose inner diameter or through hole matches the outer diameter of the valve stem 4 and is used to achieve or determine the linear movement of the valve stem 4 . Due to unavoidable manufacturing tolerances, there is a radial axia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com