Piston with sealing piece

A technology of seals and pistons, which is applied in the field of pistons, can solve the problems of flowing into the upper part of the piston cylinder, polluting the working environment, hydraulic oil loss, etc., and achieves the effects of reducing loss, saving hydraulic energy, and tight sliding fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

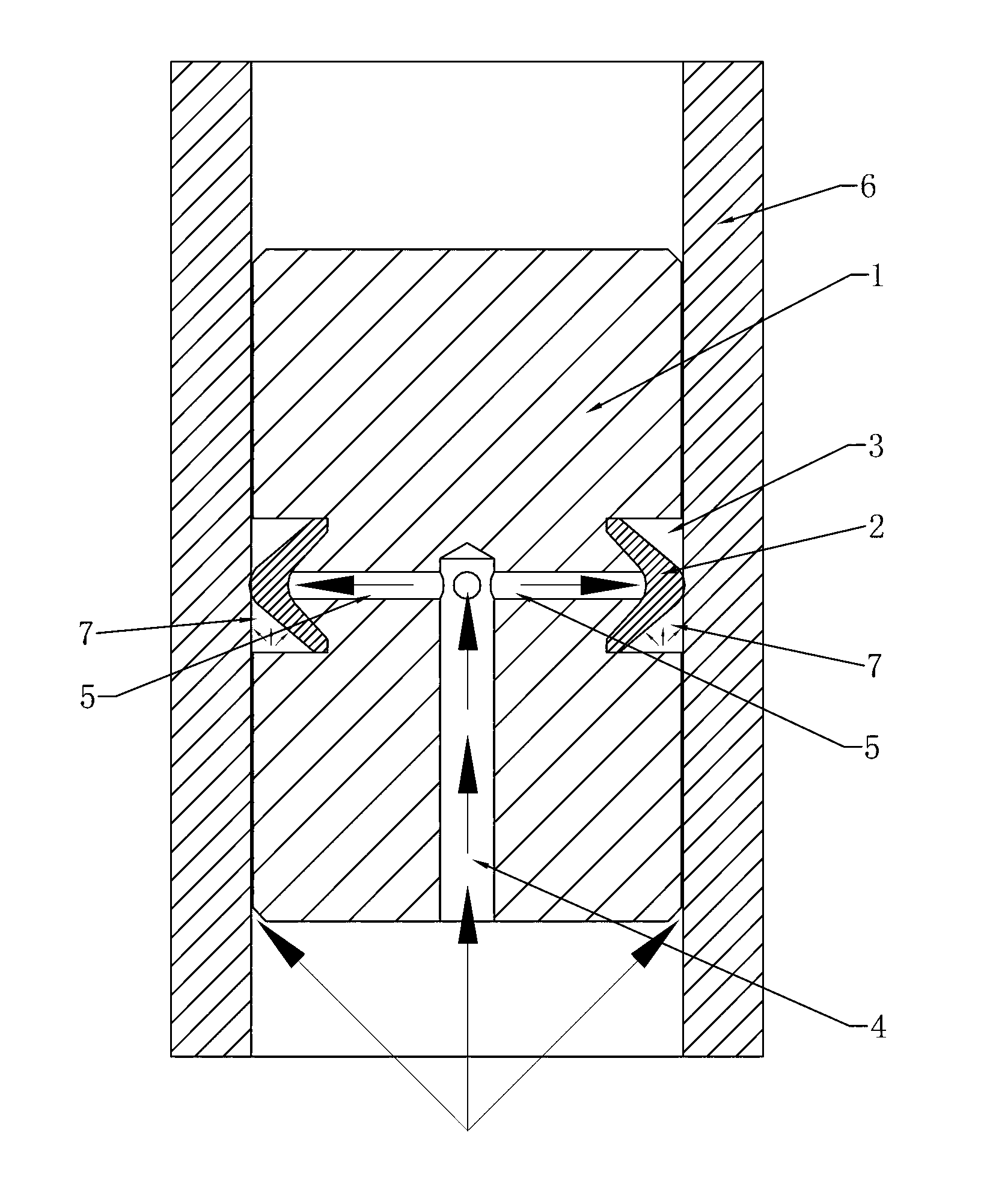

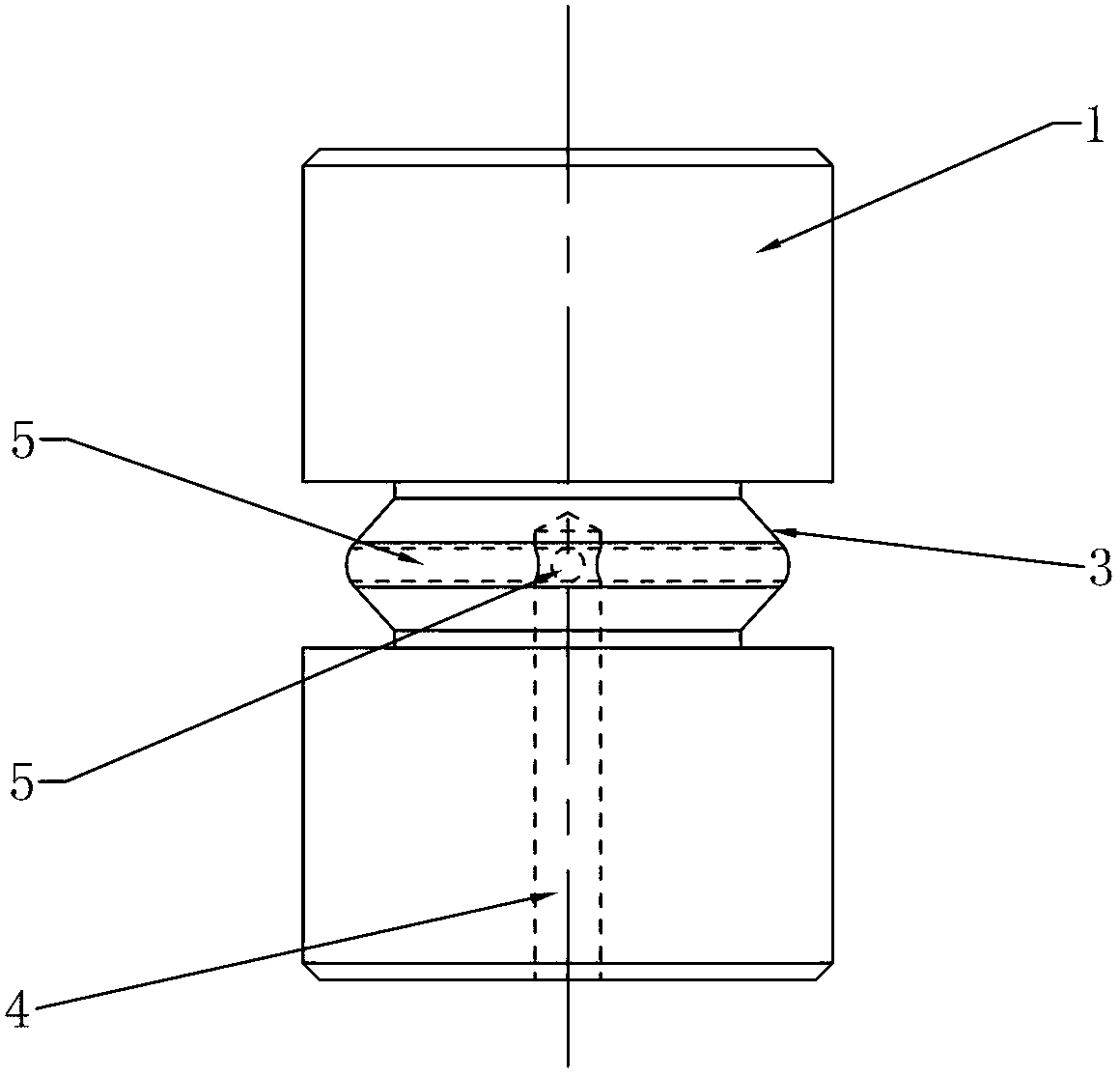

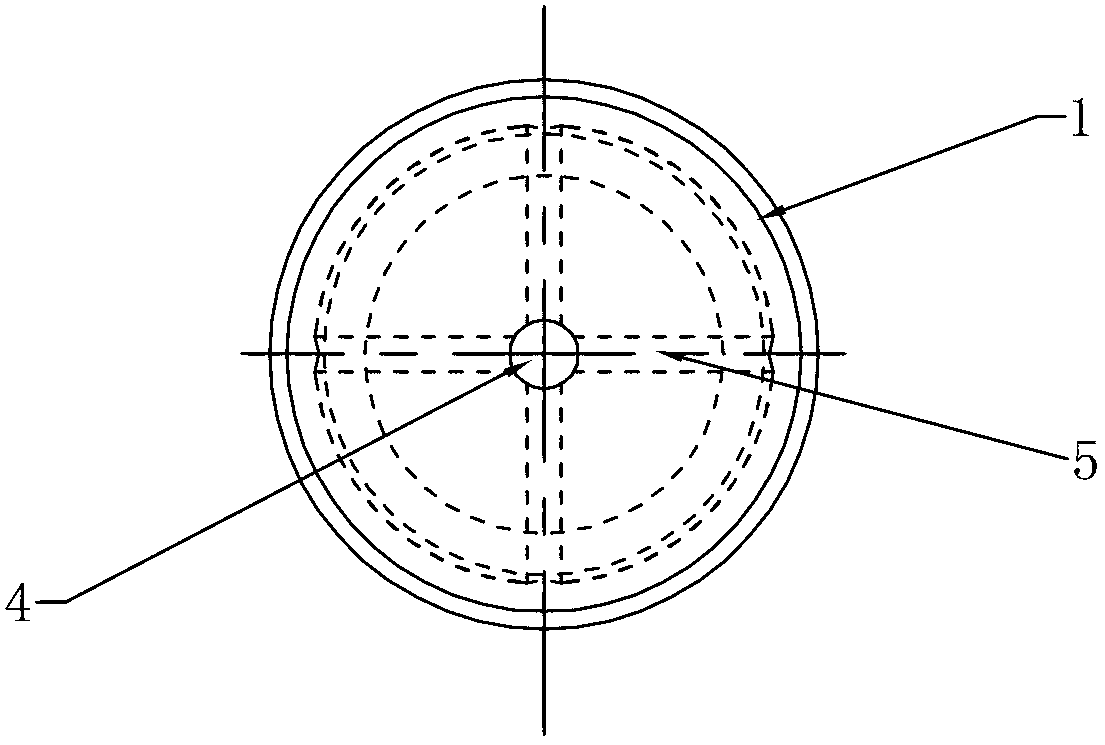

[0015] Such as figure 1 As shown, a piston with a seal in the present invention includes a piston body 1 and a seal 2 . combine Figure 5 , Image 6 As shown, the sealing member 2 is ring-shaped, the section of the sealing member 2 is V-shaped, the opening direction of the V-shaped section is inward, and the sealing member 2 is made of elastic wear-resistant material. combine figure 2 , Figure 4 As shown, the outer peripheral surface of the piston body 1 is provided with an annular groove 3 , and the bottom surface of the annular groove 3 protrudes outward. The sealing member 2 is installed in the annular groove 3, the inner surface of the sealing member 2 fits the bottom surface of the annular groove 3, and the first oil hole 4 is opened on the upper or lower end surface of the piston body 1, the first oil hole 4 is located at the center of the lower end surface of the piston body 1 . combine image 3 As shown, four second oil holes 5 are provided in the middle of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com