Sheet stacking apparatus and image forming apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

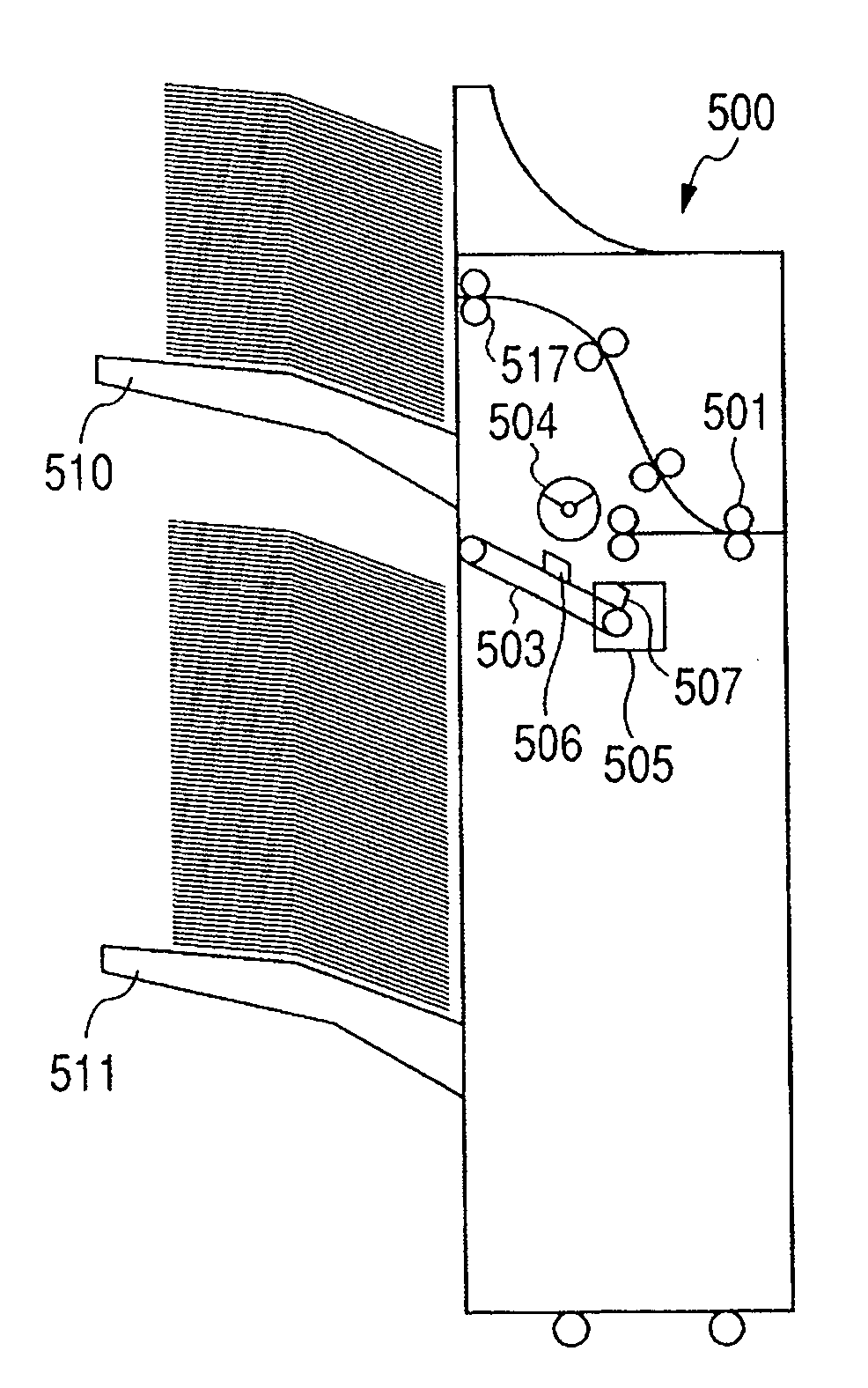

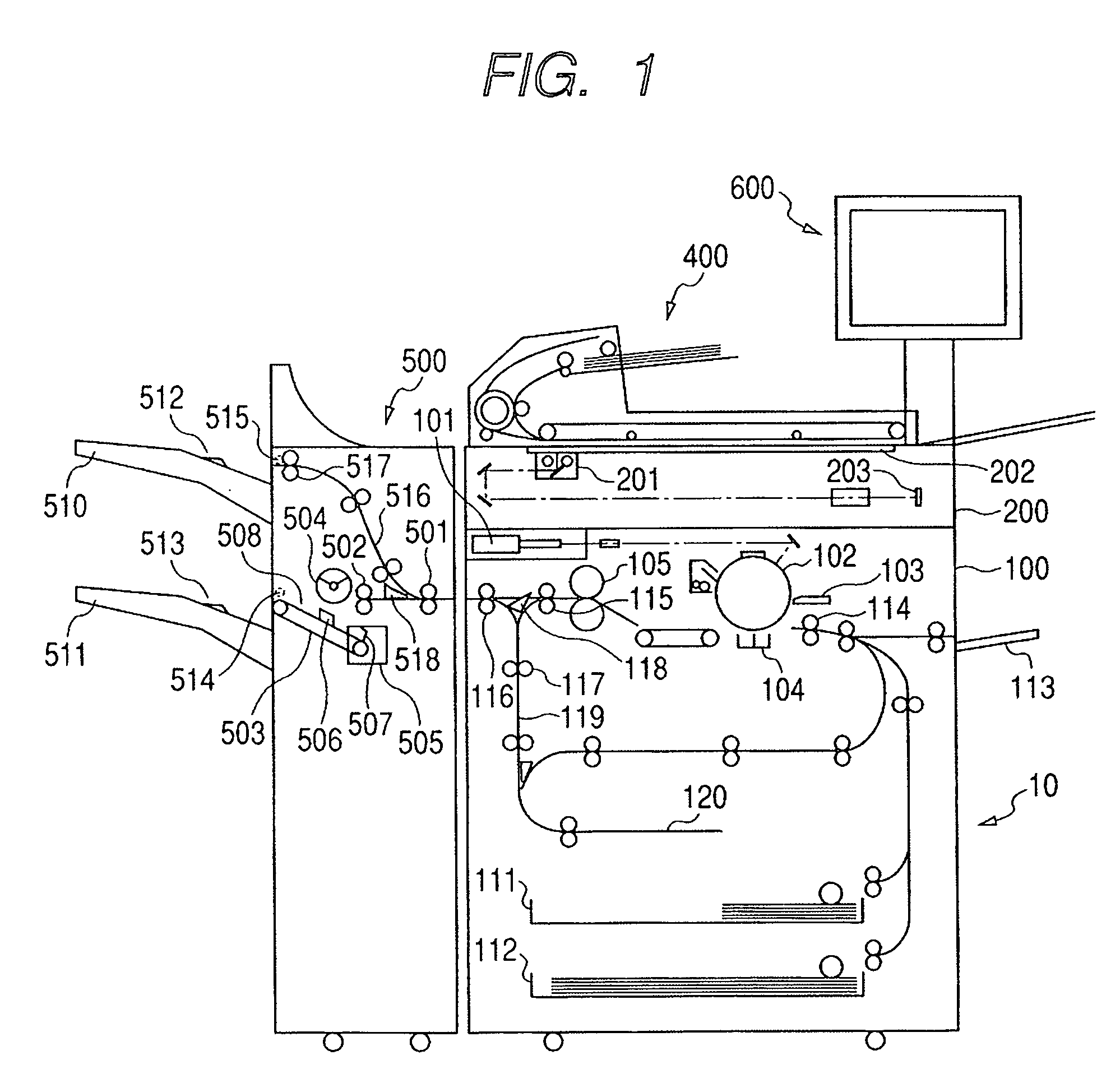

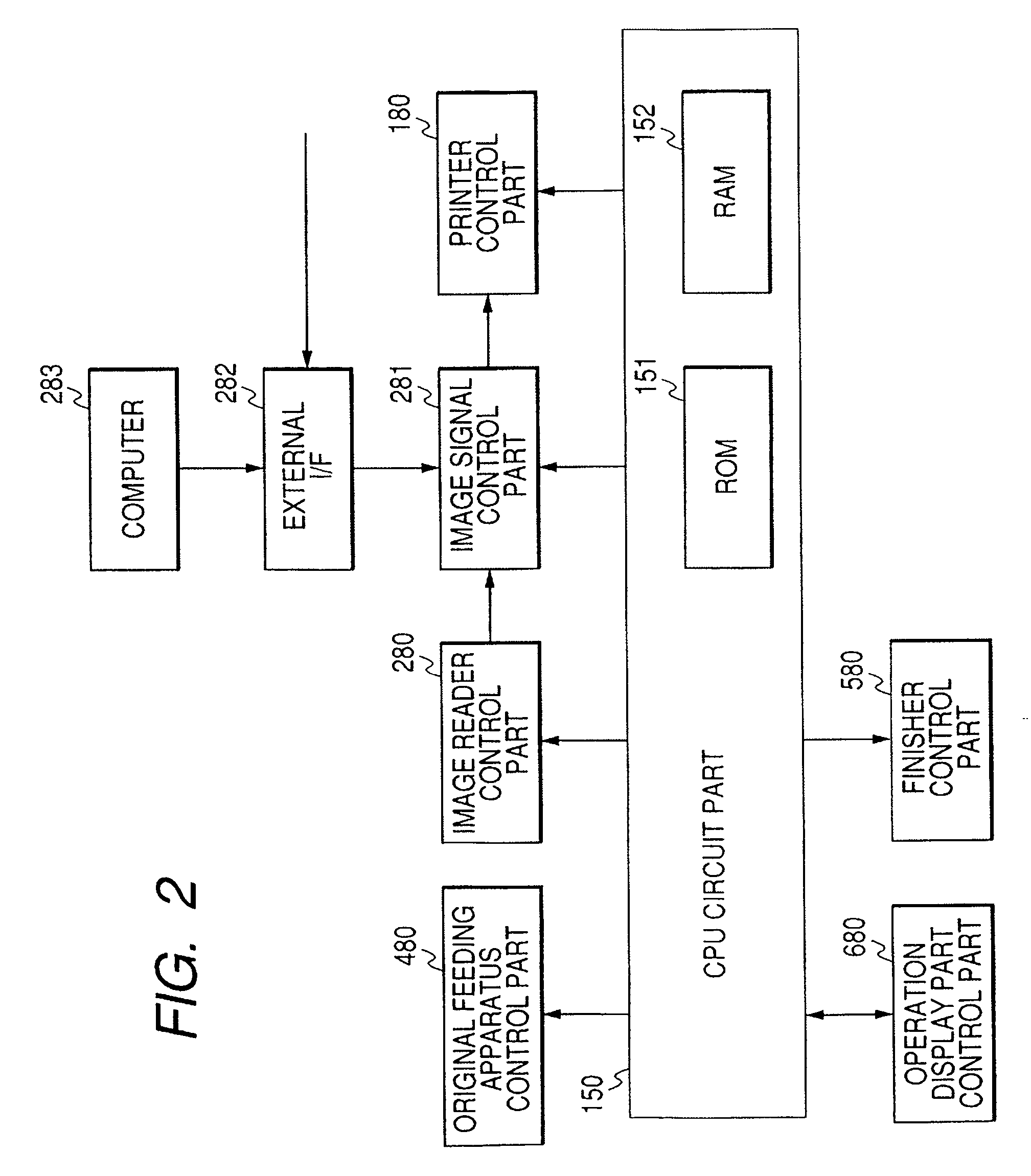

[0022] Hereafter, by referring to the accompanying drawings, preferred embodiments of the present invention are illustratively described in detail. An embodiment of an image forming apparatus having a sheet processing apparatus is described below. In this case, a copying machine is shown as an image forming apparatus and a finisher is shown as a sheet processing apparatus.

[0023] First, a schematic configuration of the whole of an image forming apparatus is described by referring to FIG. 1. FIG. 1 is a sectional view showing an internal structure of the whole of an image forming apparatus which is an embodiment of the present invention.

[0024] As shown in FIG. 1, an image forming apparatus 10 has a printer 100 serving as an image forming part and an image reader 200 serving as an image reading part. Moreover, the image forming apparatus 10 has a document feeder 400, finisher 500 serving as a sheet stacking apparatus and operation display part 600.

[0025] The document feeder 400 is m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com